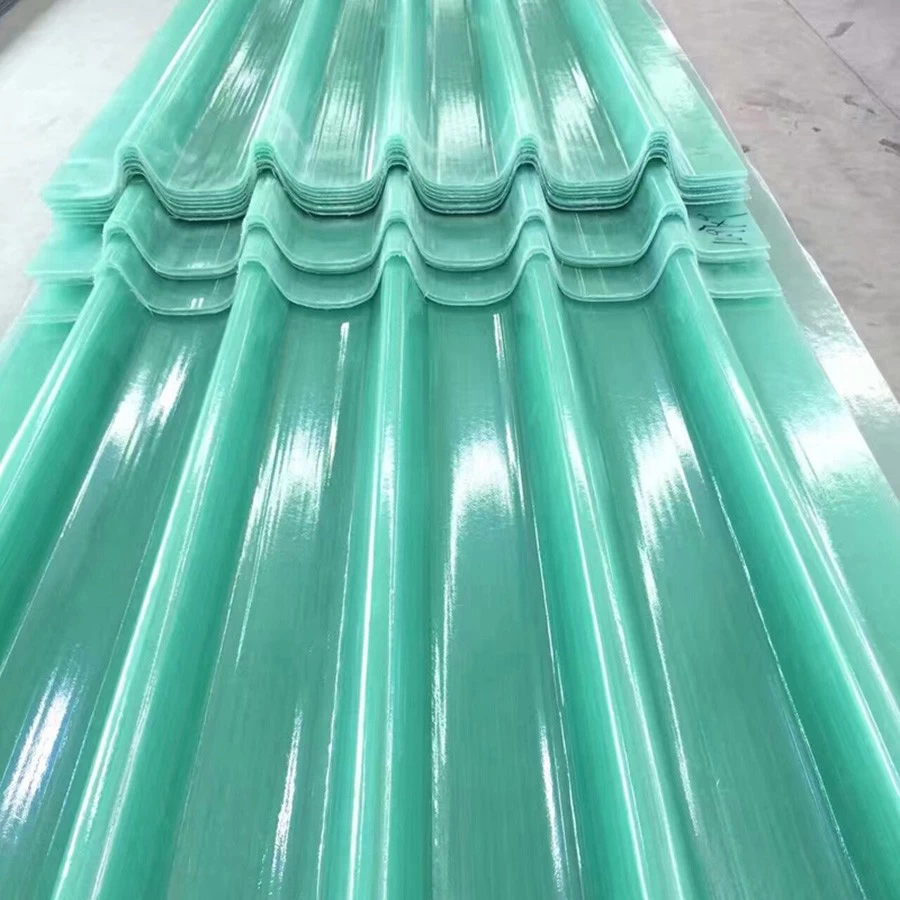

FRP (Fiber Reinforced Polymer) Composites Benefits

Arion Shu

Foreth

2018-03-06 17:55:22

Composites offer many advantages compared to traditional materials used in corrosion applications.

Corrosion Resistance: FRP composites do not rust or corrode. There are various resin systems available to the fabricator which provide long-term resistance to almost every chemical and temperature environment. Properly designed FRP composites parts have long service life and minimum maintenance as compared to most competitive materials.

Inherent Durability: There are case histories of fiberglass ductwork being in service in chemical manufacturing plants for over twenty-five years – operating in harsh chemical environments twenty-four hours a day, seven days a week. How long do composites last? In many cases, over fifty years and still counting!

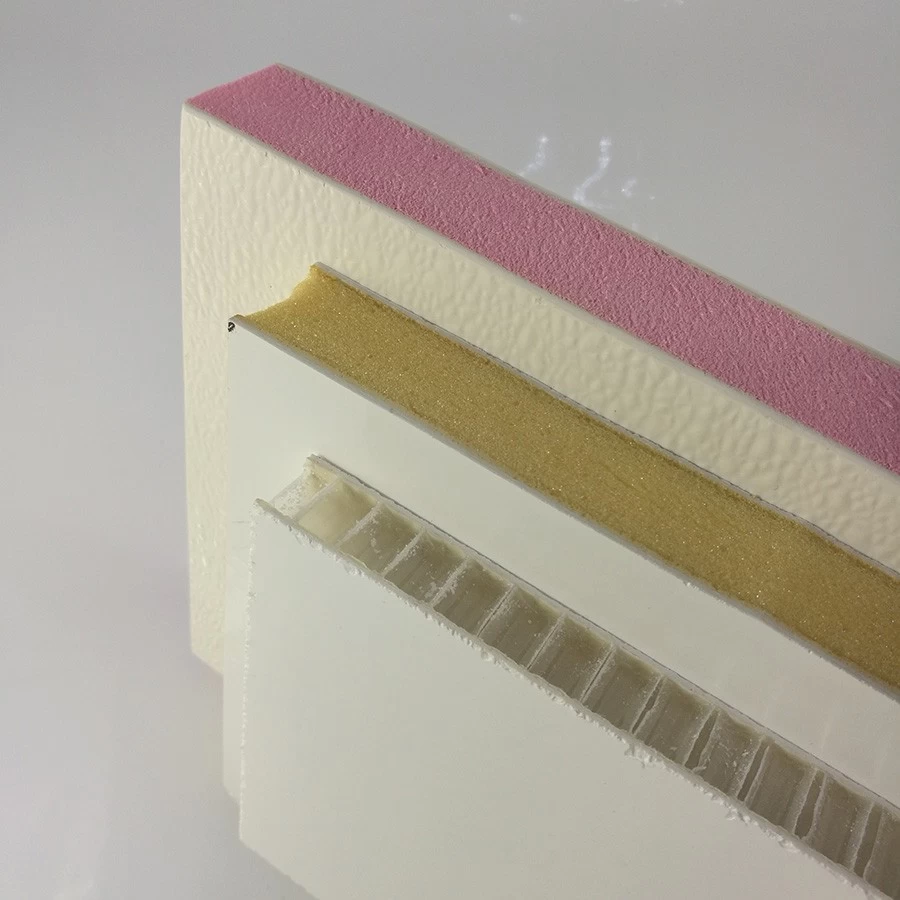

High Strength: FRP (Fiber Reinforced Polymer) composites are very effective in providing high strength components. FRP composites can be designed to provide a vast range of mechanical properties, including tensile, flexural, impact and compressive strengths. FRP composites are not isotropic, but anisotropic which allows the designer/fabricator to design a laminate with oriented reinforcement to provide strengths in specific areas or direction as the final application requires.

Lightweight: FRP composites have a higher specific strength than many of the materials used in corrosion applications. They can deliver more strength per unit of weight than most metals.

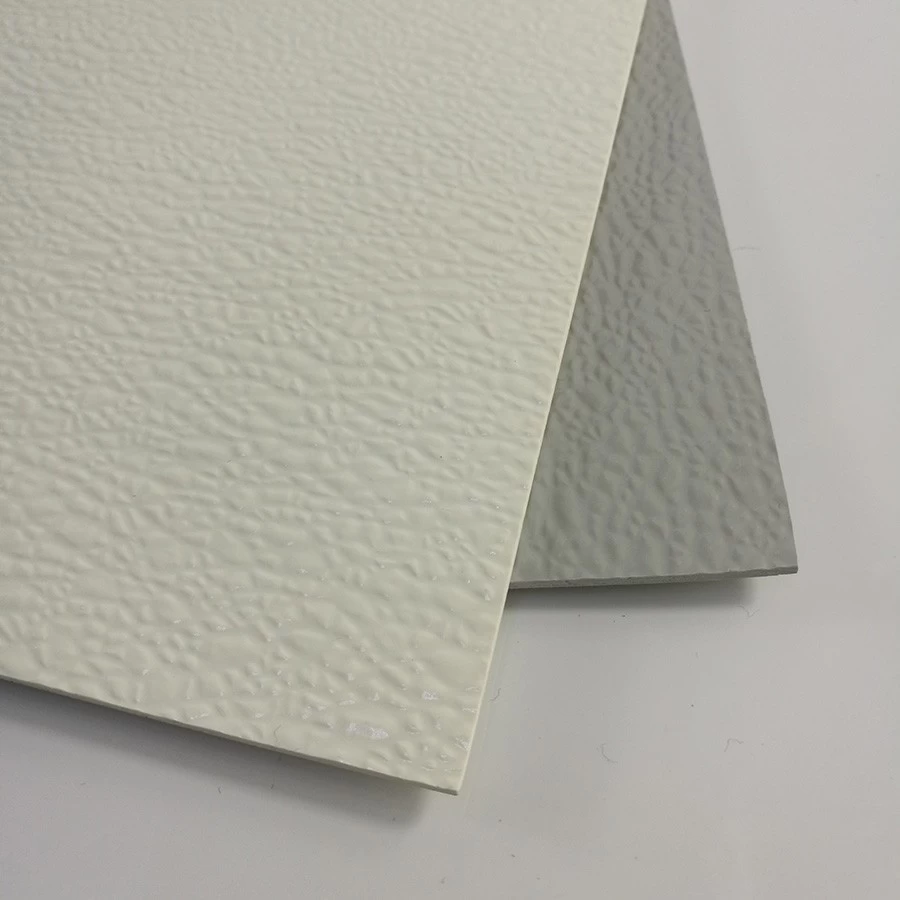

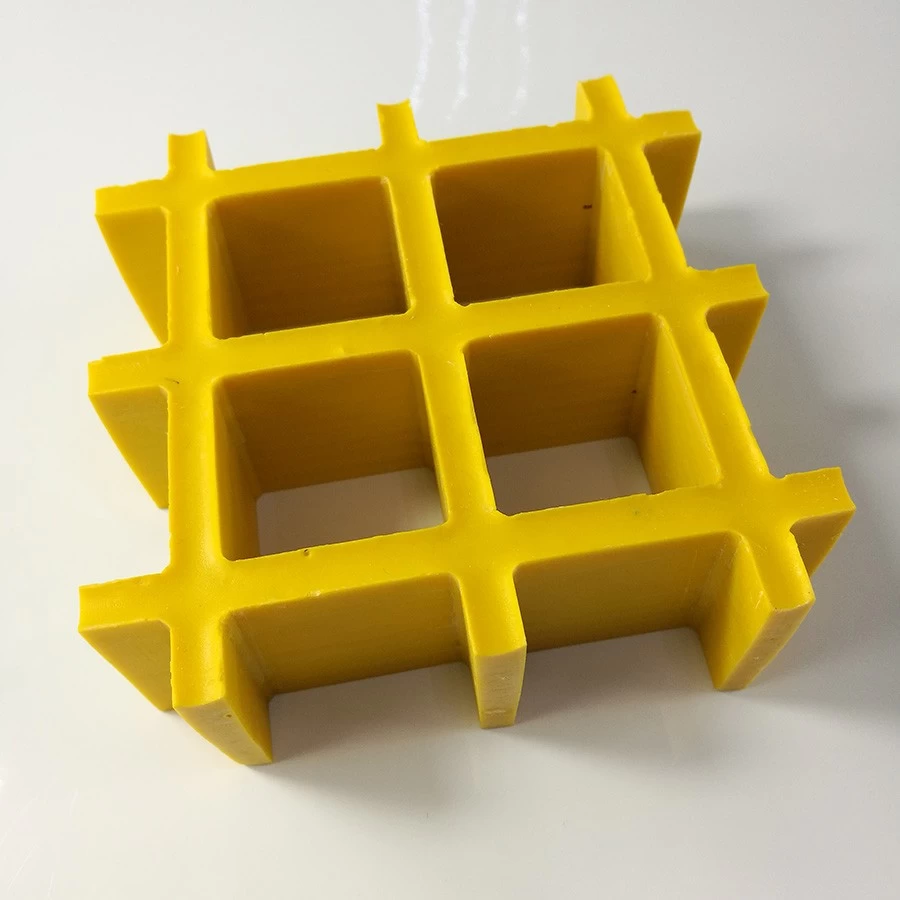

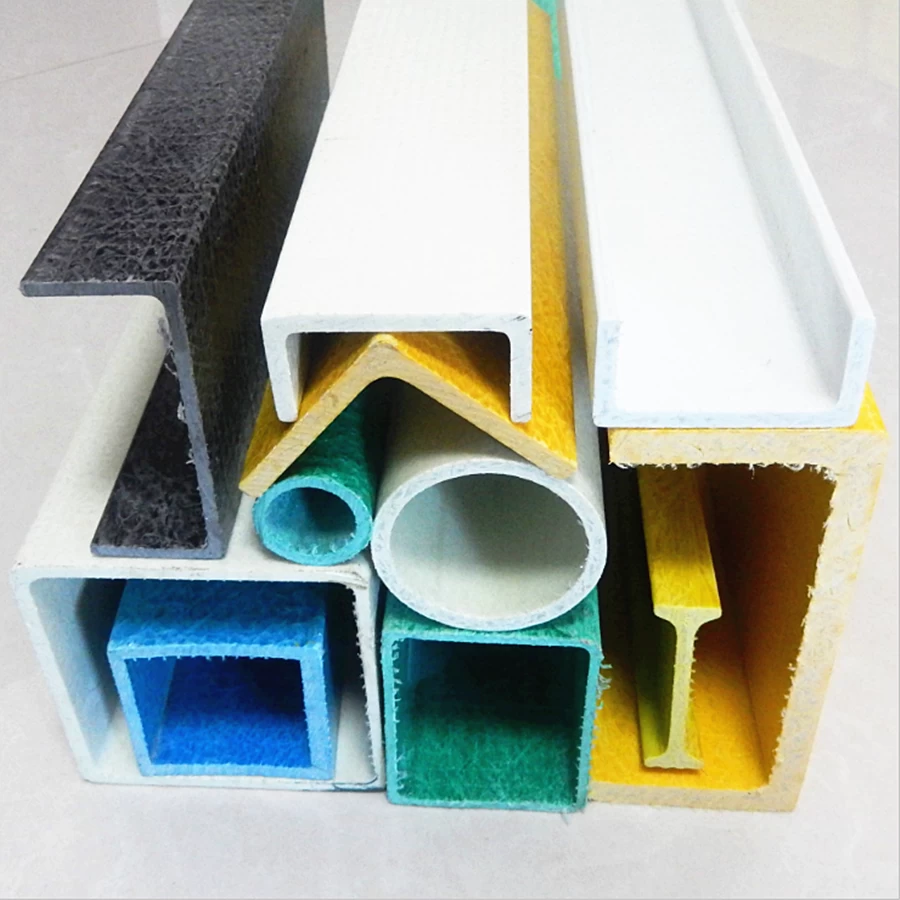

Design Flexibility: FRP composites can be fabricated into virtually any shape a designer may have in mind. A corrosion application can be complex or simple in configuration; large or small; structural, decorative or cosmetic , or all inclusive. FRP composites free designers to try new concepts, from prototype to production.

Elevated Temperature Service: FRP composite parts fabricated utilizing resins and inert filler technology perform very well in elevated temperature applications.

Thermal cycling: FRP composite parts, in large part due to the polymer matrix selected, operate in applications that experience temperature changes of more than 150o F for extended periods of time without adverse effects.

Dimensional Stability: FRP composites maintain their shape and functionality, even under severe mechanical and environmental stresses. FRP composites typically do not exhibit viscoelastic or “cold-creep” characteristics of thermoplastics. The yield point of FRP composites is generally its break point.

High Dielectric Strength: FRP composites have excellent electrical insulating properties, making them an obvious choice for current carrying applications.

Parts Consolidation: FRP composite parts often have replaced assemblies of many parts and fasteners required for traditional materials such as stainless steel.

Ability to Form Shapes: FRP composites can be formed into complex shapes easier than other competing materials. This ability gives the designer/fabricator the freedom to create any shape or configuration.

Corrosion Resistance: FRP composites do not rust or corrode. There are various resin systems available to the fabricator which provide long-term resistance to almost every chemical and temperature environment. Properly designed FRP composites parts have long service life and minimum maintenance as compared to most competitive materials.

Inherent Durability: There are case histories of fiberglass ductwork being in service in chemical manufacturing plants for over twenty-five years – operating in harsh chemical environments twenty-four hours a day, seven days a week. How long do composites last? In many cases, over fifty years and still counting!

High Strength: FRP (Fiber Reinforced Polymer) composites are very effective in providing high strength components. FRP composites can be designed to provide a vast range of mechanical properties, including tensile, flexural, impact and compressive strengths. FRP composites are not isotropic, but anisotropic which allows the designer/fabricator to design a laminate with oriented reinforcement to provide strengths in specific areas or direction as the final application requires.

Lightweight: FRP composites have a higher specific strength than many of the materials used in corrosion applications. They can deliver more strength per unit of weight than most metals.

Design Flexibility: FRP composites can be fabricated into virtually any shape a designer may have in mind. A corrosion application can be complex or simple in configuration; large or small; structural, decorative or cosmetic , or all inclusive. FRP composites free designers to try new concepts, from prototype to production.

Elevated Temperature Service: FRP composite parts fabricated utilizing resins and inert filler technology perform very well in elevated temperature applications.

Thermal cycling: FRP composite parts, in large part due to the polymer matrix selected, operate in applications that experience temperature changes of more than 150o F for extended periods of time without adverse effects.

Dimensional Stability: FRP composites maintain their shape and functionality, even under severe mechanical and environmental stresses. FRP composites typically do not exhibit viscoelastic or “cold-creep” characteristics of thermoplastics. The yield point of FRP composites is generally its break point.

High Dielectric Strength: FRP composites have excellent electrical insulating properties, making them an obvious choice for current carrying applications.

Parts Consolidation: FRP composite parts often have replaced assemblies of many parts and fasteners required for traditional materials such as stainless steel.

Ability to Form Shapes: FRP composites can be formed into complex shapes easier than other competing materials. This ability gives the designer/fabricator the freedom to create any shape or configuration.