ABS Sheet Performance and Applications

Arion Shu

Foreth

2018-05-11 22:45:01

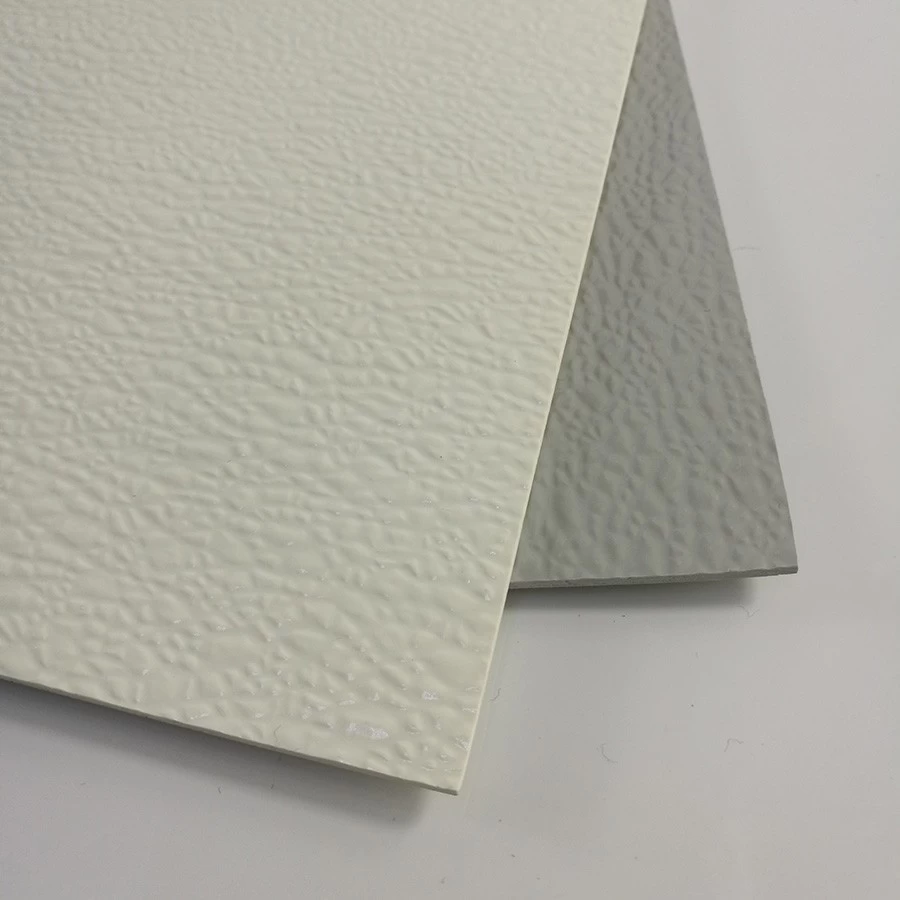

ABS sheet is an emerging material in the plastic sheet industry. The full name is Acrylonitrile butdiene styrene. It is a polymer with a relatively large output and a wide range of applications. It combines the various performances of PS, SAN, and BS and combines the excellent mechanical properties of toughness, stiffness, and rigidity.

ABS Main Performance:

1. ABS has excellent mechanical properties, its excellent impact strength, can be used at very low temperatures; ABS excellent wear resistance, dimensional stability, and oil resistance, can be used for bearings under medium load and speed. The bending strength and compressive strength of ABS are inferior in plastics. The mechanical properties of ABS are greatly affected by temperature.

2. ABS is not affected by water, inorganic salts, alkalis, and various acids, but it is soluble in ketones, aldehydes, and chlorinated hydrocarbons, and is eroded by glacial acetic acid, vegetable oils, etc., and can cause stress cracking. ABS has poor weatherability and is easily degraded under the action of ultraviolet light; after half a year outdoors, the impact strength is reduced by half.

3. ABS sheet has excellent impact strength, dimensional stability, dyeing, molding and machining, high mechanical strength, high stiffness, low water absorption, good corrosion resistance, simple connection, non-toxic, tasteless, and excellent Chemical properties and electrical insulation properties. It can be heat-resistant without deformation and has high impact toughness under low temperature conditions. It is also a hard, hard-to-scratch, hard-to-deform material. Low water absorption; high dimensional stability. The conventional ABS board is not very white, but its toughness is very good. It can be cut with a shear, or it can be opened.

4. The heat distortion temperature of ABS is 93~118°C, and the product can be increased by about 10°C after being annealed. ABS can still exhibit certain toughness at -40°C, and can be used within the temperature range of -40°C to 100°C.

5. ABS plate is prone to internal stress and causes deformation of the plate during processing. Therefore, ABS plate must be stress-removed before use.

ABS Main Applications

1. Automobile interior and exterior decoration: instrument panel, decorative column, instrument front cover, grille, interior and exterior trim

2. Office Equipment Cases: Notebooks/Desktops, Copiers, Printers, Monitors, etc.

3. Telecom, mobile phone housing, radome

4. Electrical Products, Electronics Enclosures, Meter Covers and Housings

5. Household appliances, such as washing machines, hair dryers, microwave ovens, internal and external components