Can Flame-retardant Fiberglass Lighting Roofing Panels Be Still Used After Yellowing?

Arion Shu

Foreth

2018-04-03 16:15:40

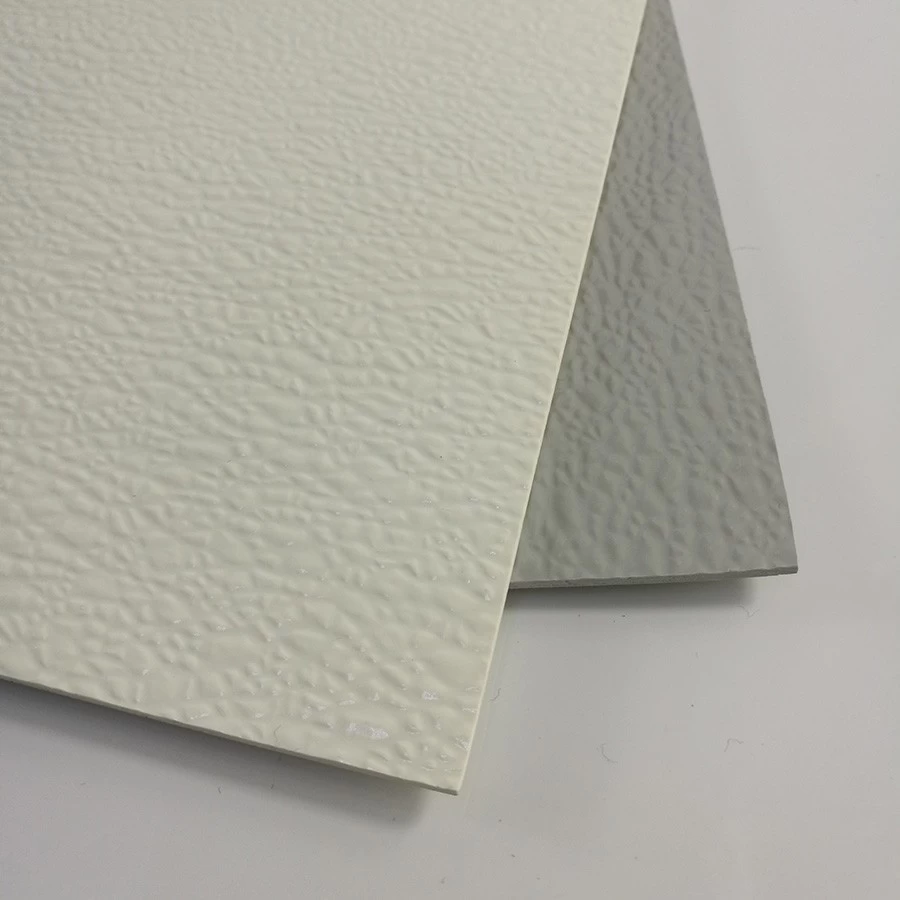

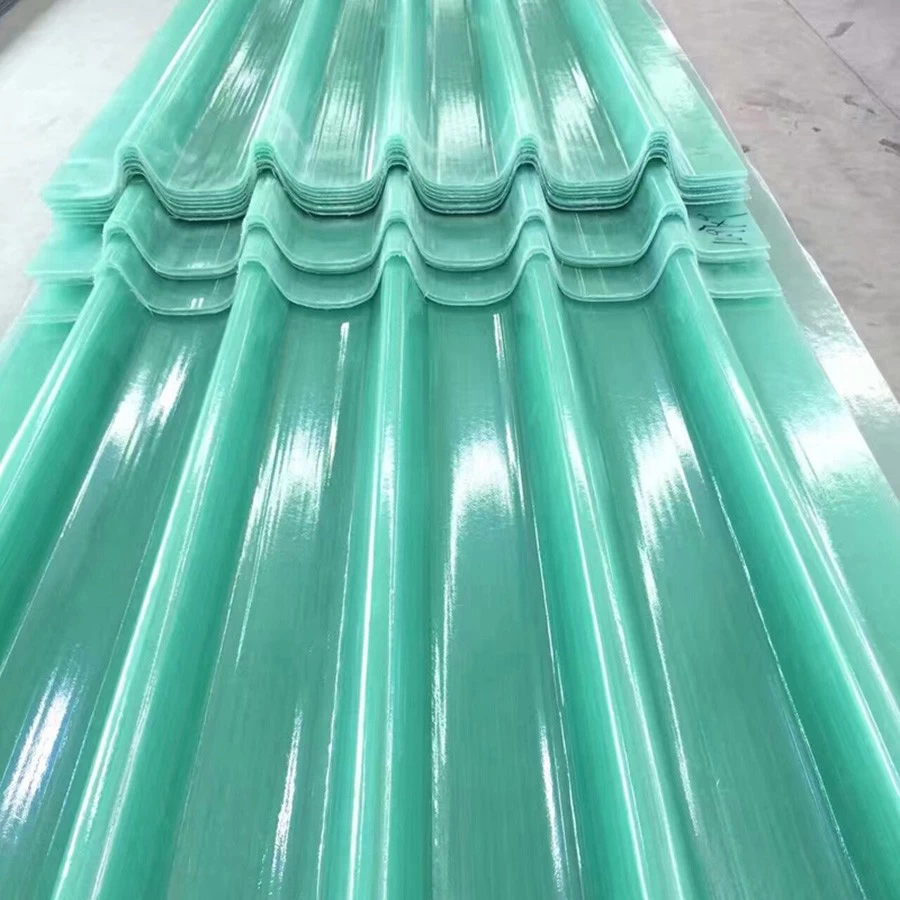

B. The flame retardant series of FRP lighting roofing panels and FRP plates currently produced by our company are classified into primary flame retardant (F1 grade, oxygen index>30) and secondary flame retardant (F2 grade, oxygen index>26). The F1 grade flame-retardant lighting rooing panel is produced by using a resin containing a flame-retardant component in its molecular structure (also called a reactive flame-retardant resin); F2 grade flame-retardant lighting roof panel is produced by using a flame-retardant additive (also called an additive-type resistance resin).

C, The flame retardant lighting roof panel compared to the general lighting roof panel and FRP plate, due to the presence of flame-retardant components in the resin material, so its aging resistance and yellowing resistance is slightly poor. After testing, F2 grade of flame-retardant lighting roof panel will show signs of yellowing after one year, and F1 flame-retardant lighting roof panel will experience slight yellowing followed by Yellowing will become more apparent as time passes.

In summary: Flame-retardant FRP lighting roof panels are easier to turn yellow than general FRP lighting roof panel and FRP plates, but they will not affect quality. Only the light transmission rate will decrease with the increase of service life. However, the yellowing does not represent the end of the lifespan of the lighting tile, and the mechanical properties of the lighting tile, such as mechanical strength, remain basically unchanged and can still meet the requirements of its use. Therefore, our commitment to the warranty 15 years.