Fiberglass Reinforced Panels FAQ’s

Arion Shu

Foreth

2018-03-07 15:11:35

Q: Can Fiber Reinforced Panels be installed over most substrates?

A: Fiber reinforced panels could be installed almost on all substrates. However, the installation method used will vary from one substrate to another.

Q: How to Install Fiberglass reinforced panels over Drywall?

A: Yes, FRP can be installed almost on all substrates by mechanical installation method. However if the contractor wants to install Fiberglass reinforced panels using adhesives, it could be done, just need to use solvent free adhesive only over porous surfaces such as concrete block, drywall, plywood or plaster walls. When installing FRP over non-porous surfaces, such as wall tiles, using a solvent base adhesive with rivets is recommended, In order to complete a better installation, remember to sand the tiles so the FRP could adhere better.

Q: Does Fiberglass reinforced panels could be installed flat against the wall?

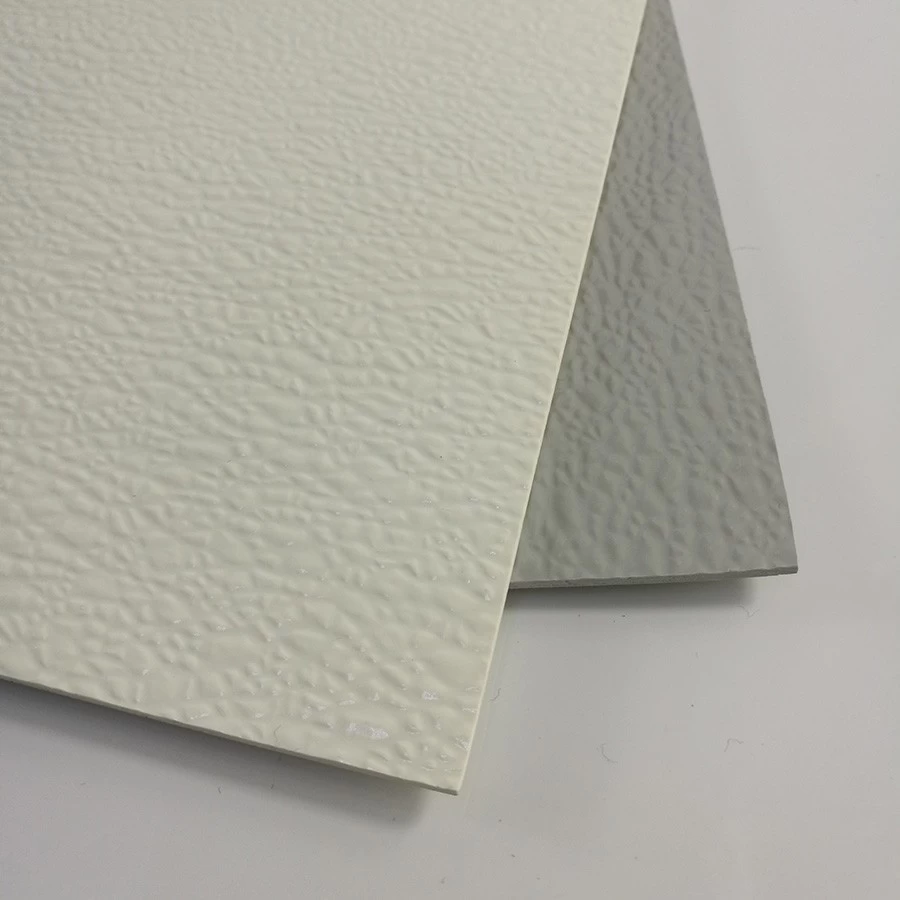

A: FRP panels are so flexible so it can be installed flat against the wall. But remember as any building material, it will expand and contract according to environmental conditions where it was installed.

Q: What tools are required to install FRP?

A: The installation of FRP could be done by using: a fine tooth saw blade, carbide drill bit, the manufacturer’s recommended trowel, and a laminate roller that will be used to ensure maximum adhesion between FRP and the surface where it is being installed.

Q: In what size does FRP is manufactured?

A: Fiberglass reinforced panels usually are manufactured in 4 foot by 8 foot sections and with some architectural trims and/or moldings. For small applications and surfaces the FRP could be cut to exact dimensions by using a power saw with a fine tooth, carbide tip blades or masonry blades. FRP Panels in 0.090” thickness weigh about 12 ounces per square foot. A skid of 100 – 4x8’ panels weighs approximately 2000 pounds each.

Q: What could be a possible solution and faster installation procedure?

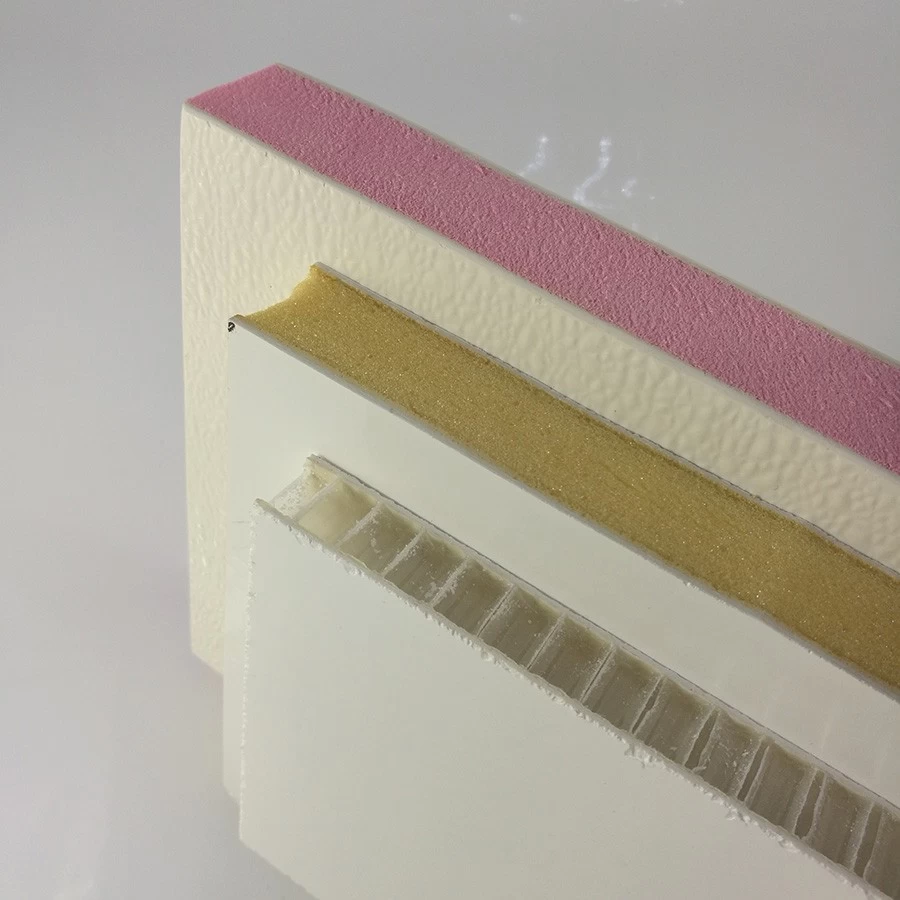

A: Fiberglass reinforced panels could be supplied with pre-laminated sheets of plywood, EPS insulation or drywall. By using this type of FRP, it will allow a faster installation and will produce a smoother surface, because it eliminates the need for rivets. It is also recommended before installing FRP to remove the packing of the panels, in the area where it will be installed.

FRP ideally will absorb the same environmental conditions of the place where the panels will be installed.

A: Fiber reinforced panels could be installed almost on all substrates. However, the installation method used will vary from one substrate to another.

Q: How to Install Fiberglass reinforced panels over Drywall?

A: Yes, FRP can be installed almost on all substrates by mechanical installation method. However if the contractor wants to install Fiberglass reinforced panels using adhesives, it could be done, just need to use solvent free adhesive only over porous surfaces such as concrete block, drywall, plywood or plaster walls. When installing FRP over non-porous surfaces, such as wall tiles, using a solvent base adhesive with rivets is recommended, In order to complete a better installation, remember to sand the tiles so the FRP could adhere better.

Q: Does Fiberglass reinforced panels could be installed flat against the wall?

A: FRP panels are so flexible so it can be installed flat against the wall. But remember as any building material, it will expand and contract according to environmental conditions where it was installed.

Q: What tools are required to install FRP?

A: The installation of FRP could be done by using: a fine tooth saw blade, carbide drill bit, the manufacturer’s recommended trowel, and a laminate roller that will be used to ensure maximum adhesion between FRP and the surface where it is being installed.

Q: In what size does FRP is manufactured?

A: Fiberglass reinforced panels usually are manufactured in 4 foot by 8 foot sections and with some architectural trims and/or moldings. For small applications and surfaces the FRP could be cut to exact dimensions by using a power saw with a fine tooth, carbide tip blades or masonry blades. FRP Panels in 0.090” thickness weigh about 12 ounces per square foot. A skid of 100 – 4x8’ panels weighs approximately 2000 pounds each.

Q: What could be a possible solution and faster installation procedure?

A: Fiberglass reinforced panels could be supplied with pre-laminated sheets of plywood, EPS insulation or drywall. By using this type of FRP, it will allow a faster installation and will produce a smoother surface, because it eliminates the need for rivets. It is also recommended before installing FRP to remove the packing of the panels, in the area where it will be installed.

FRP ideally will absorb the same environmental conditions of the place where the panels will be installed.