How to Choose Refrigerated Truck Body Panels

Arion Shu

Foreth

2018-03-30 11:33:48

The body of a refrigerated truck is different from an ordinary van, and it needs good sealing performance and heat insulation effect, so as to ensure that the refrigerated cargo is in a stable temperature environment.

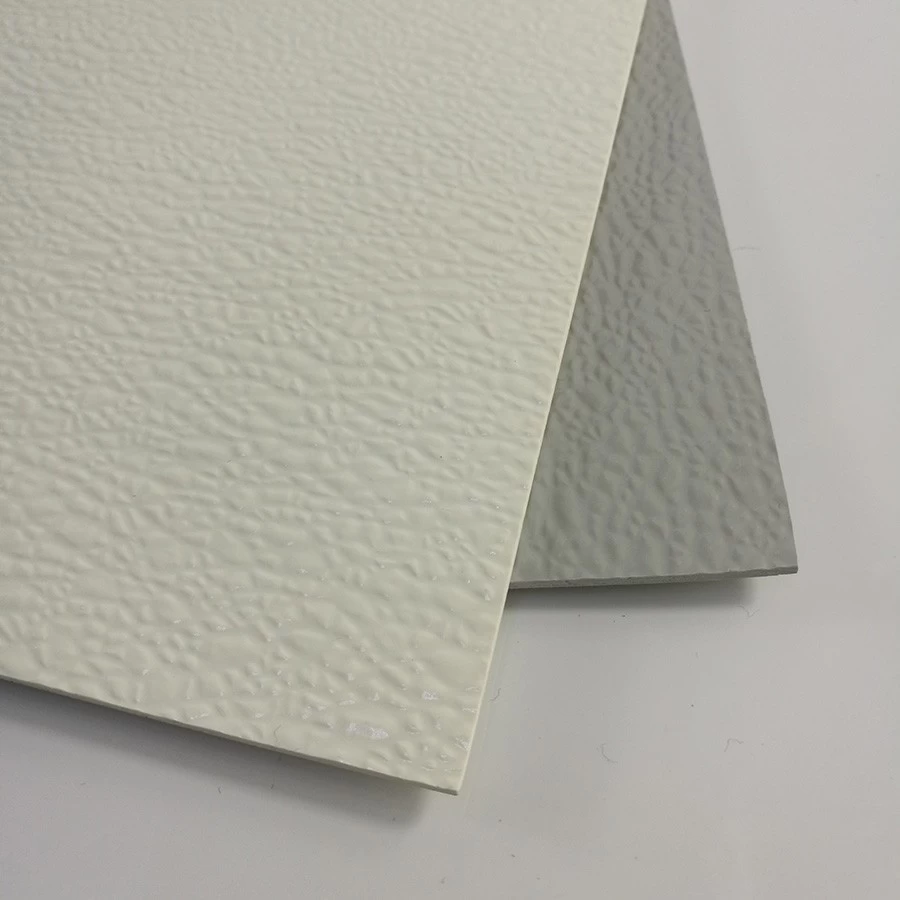

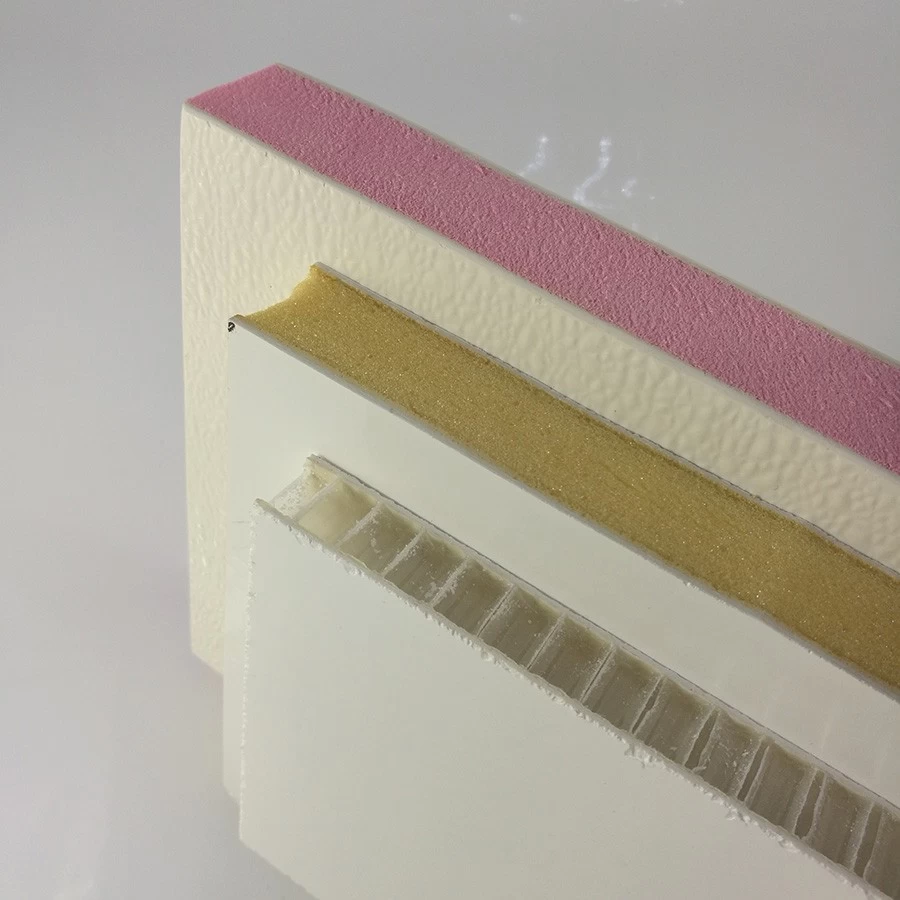

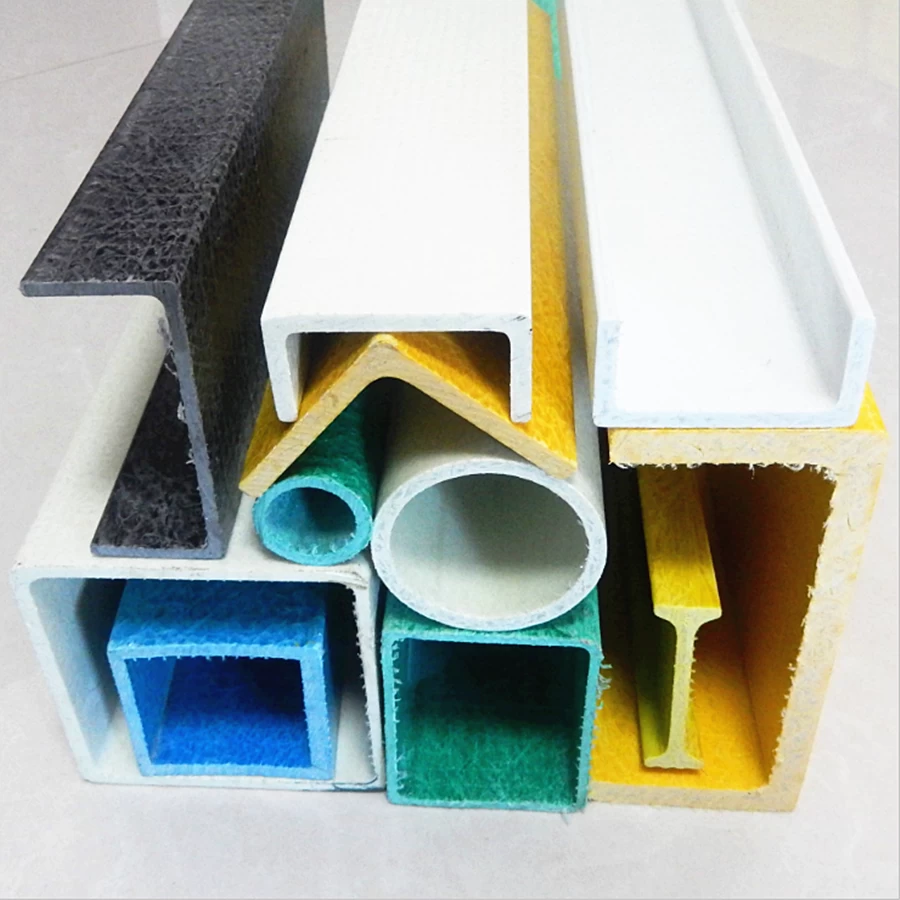

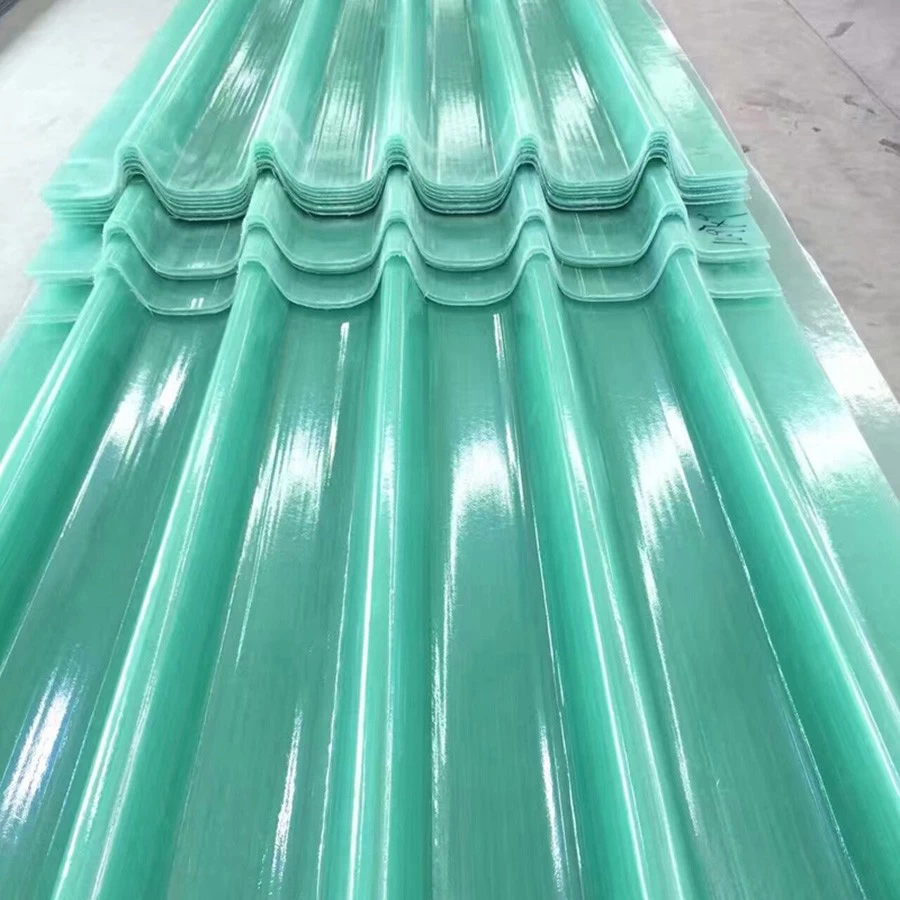

Refrigerated van compartment design is mainly airtight performance and thermal insulation performance. Generally, the structure of refrigerated truck adopts three-layer structure. The inner and outer skin are made of composite materials, such as FRP plate, color steel plate, aluminum alloy and other materials. The inner plate material should be made of different materials for transporting different goods. The most expensive inner material plate should be a stainless steel plate. The middle sandwich is a heat-insulating material, and polyurethane foam is mainly used. On the four sides, high-strength adhesive is used to bond the FRP plate with polyurethane foam to form a closed plate.

Refrigerated van compartment design is mainly airtight performance and thermal insulation performance. Generally, the structure of refrigerated truck adopts three-layer structure. The inner and outer skin are made of composite materials, such as FRP plate, color steel plate, aluminum alloy and other materials. The inner plate material should be made of different materials for transporting different goods. The most expensive inner material plate should be a stainless steel plate. The middle sandwich is a heat-insulating material, and polyurethane foam is mainly used. On the four sides, high-strength adhesive is used to bond the FRP plate with polyurethane foam to form a closed plate.

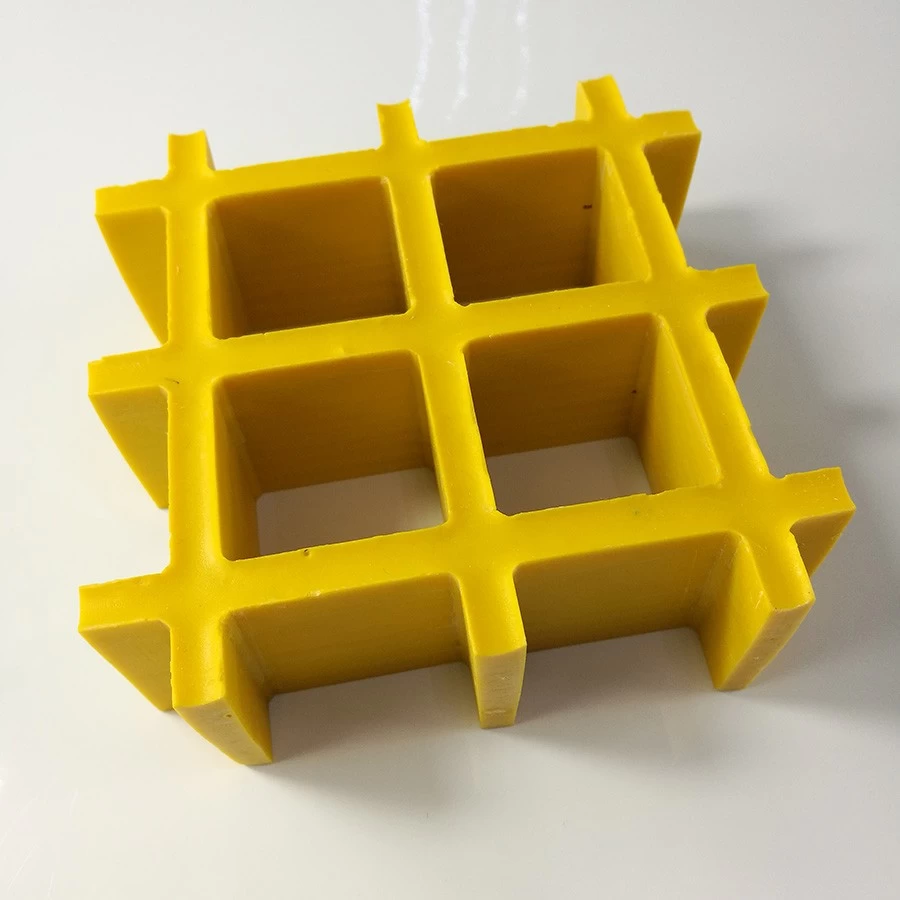

Due to cost, installation and construction, the refrigerated truck van panels were gradually made of FRP composite panels. FRP composite panels are made of FRP flats and used as two layers of the bottom and the top, in addition to the role of controlling the weight, and also have good impact resistance. The middle layer uses different kinds of core materials, such as PP honeycomb core material, XPS core material, PU core material, etc., which have better heat-insulating properties and are used for composite FRP composite panels. At the same time, high-quality polyurethane glue is used for bonding between the panel and the core material, and the adhesiveness is extremely strong. FRP composite panels have the advantages of light weight, high strength, strong impact resistance, good thermal insulation performance, corrosion resistance, etc., and are suitable for the production of refrigerated truck compartment panels.

In addition to materials, the thickness of the cargo compartment also determines the effect of insulation. The thicker the insulation layer of the cargo bed, the better the insulation effect. However, the space inside the cargo compartment will be reduced, and the cargo load will be reduced. The user needs to be based on his own Need to choose the appropriate thickness.

In addition to materials, the thickness of the cargo compartment also determines the effect of insulation. The thicker the insulation layer of the cargo bed, the better the insulation effect. However, the space inside the cargo compartment will be reduced, and the cargo load will be reduced. The user needs to be based on his own Need to choose the appropriate thickness.