- Browse Categories

- FRP Product

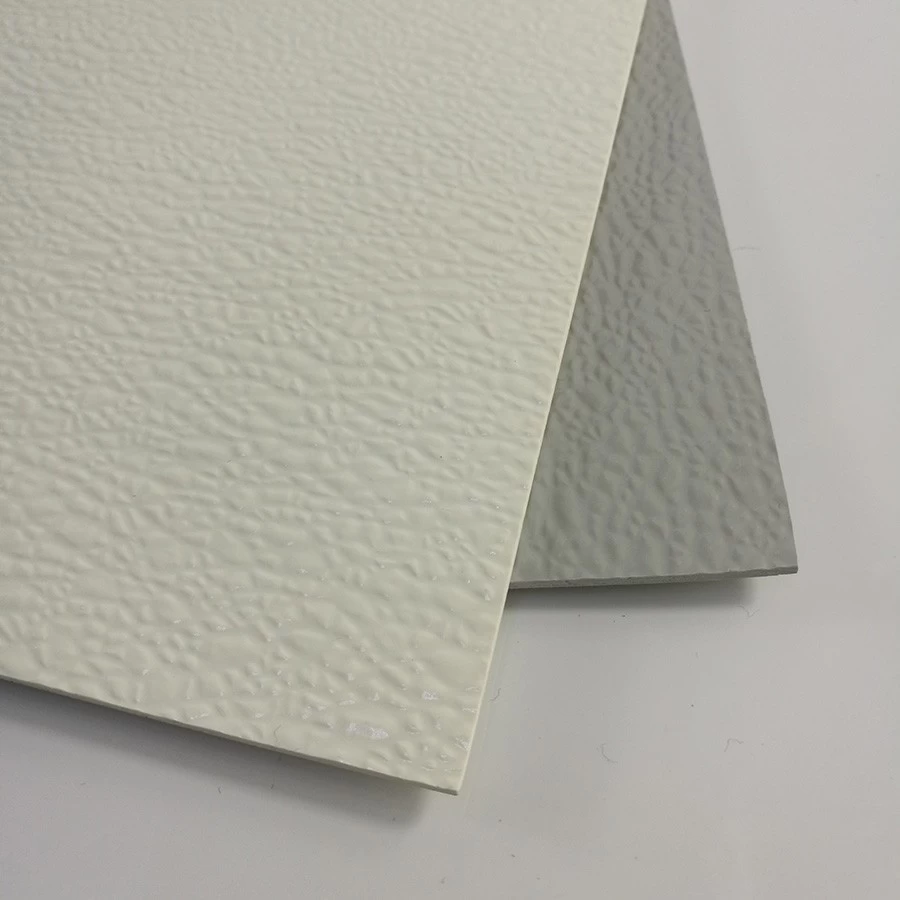

- FRP Sheet

- FRP Panel

- FRP Grating

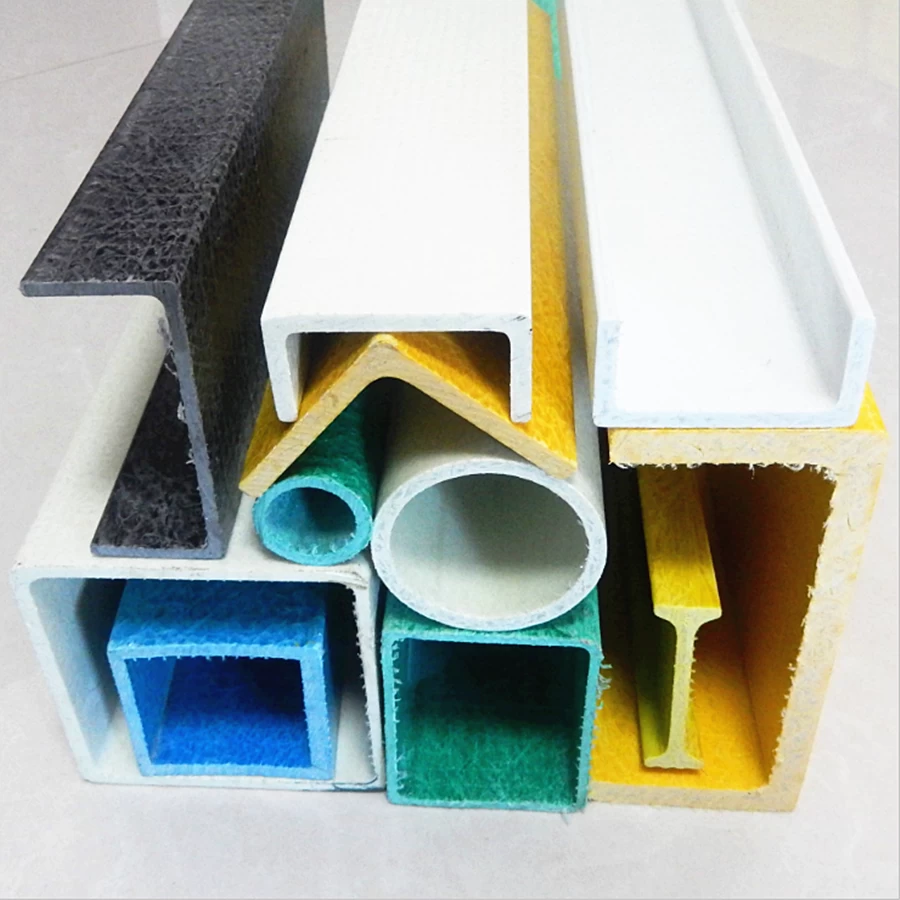

- FRP Profiles

- FRP Roofing Sheet

- FRP Manhole Cover

- FRP Sandwich Panel

- Plastic Product

- Subscribe

-

Get email updates on new products

- Contact Us

-

Telephone: +86-0755-28329102

Mobile Phone: +86-15814411453

Fax: +86-755-28998345

Address:Room 02, 32 Floor, 6 block, Phase 3, Xieli Garden, Longcheng Street, Longgang District, Shenzhen

Zip:518172

Country/Region:China (Mainland)

Province/State:Guangdong

City:Shenzhen Contact Now

- FRP Product

- News

-

How to Choose Refrigerated Truck Body Panels

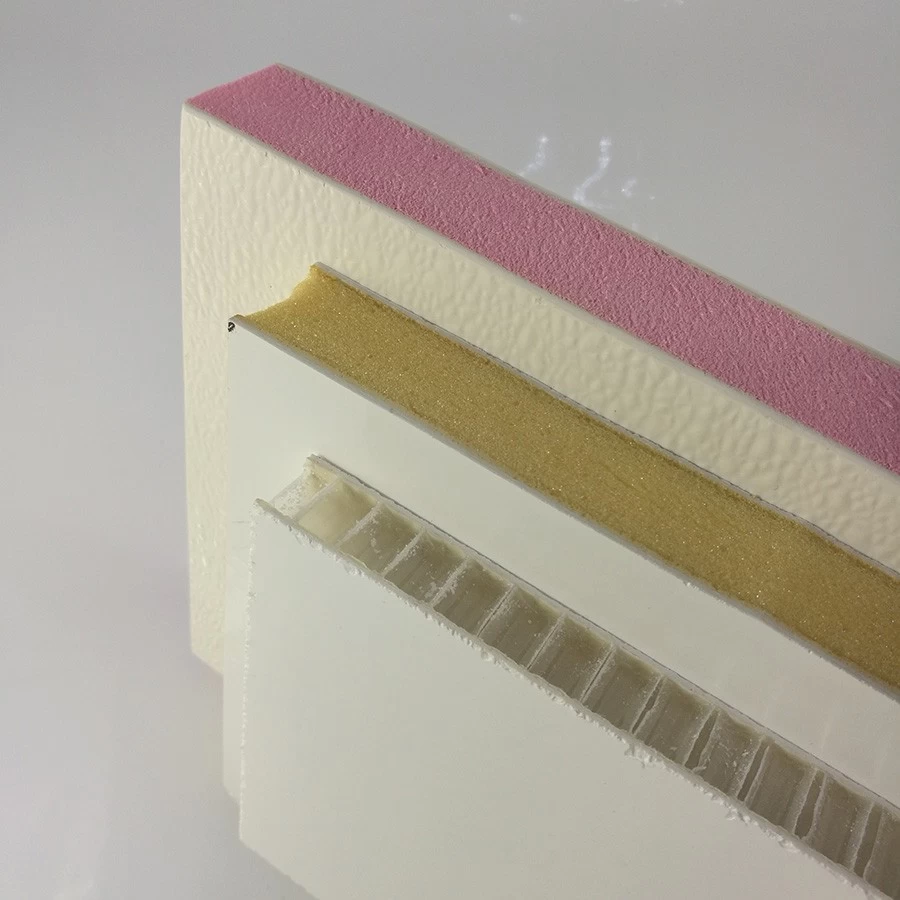

Due to cost, installation and construction, the refrigerated truck van panels were gradually made of FRP composite panels. FRP composite panels are made of FRP flats and used as two layers of the bottom and the top, in addition to the role of controlling the weight, and also have good impact resistance. The middle layer uses different kinds of core materials, such as PP honeycomb core material, XPS core material, PU core material, etc.,The differences between FRP mechanism sheet and Hand Lay-up sheets

At the beginning of the industry, manpower was usually used to make FRP, but most manufacturers use production line to produce FRP sheet now. FRP mechanism sheet gradually replaced hand lay-up sheet. The FRP mechanism sheet has many advantages over the hand lay-up. The FRP mechanism plate has stable quality and uniform thickness. Cost-effective, neat and shiny surface.Hydroponics Overview Technique and Advantages

1) Hydroponic OverviewHydroponics is a new type of plant soilless culture method, also known as nutrient solution culture. Its core is to directly inf...ABS Sheet Performance and Applications

ABS sheet is an emerging material in the plastic sheet industry. The full name is Acrylonitrile butdiene styrene. It is a polymer with a relatively la...Can Flame-retardant Fiberglass Lighting Roofing Panels Be Still Used After Yellowing?

A, Fire-retardant FRP lighting roofing panels are mainly used in steel mills and blast furnaces with high temperatures, fire point splashes or some sp...RV Traveling Are Getting More and More Popular

Do you know what a RV is? The concept of the beginning of RV is “movable house”. The RV has all the necessary items for life, including bedr...FRP Gratings Applications

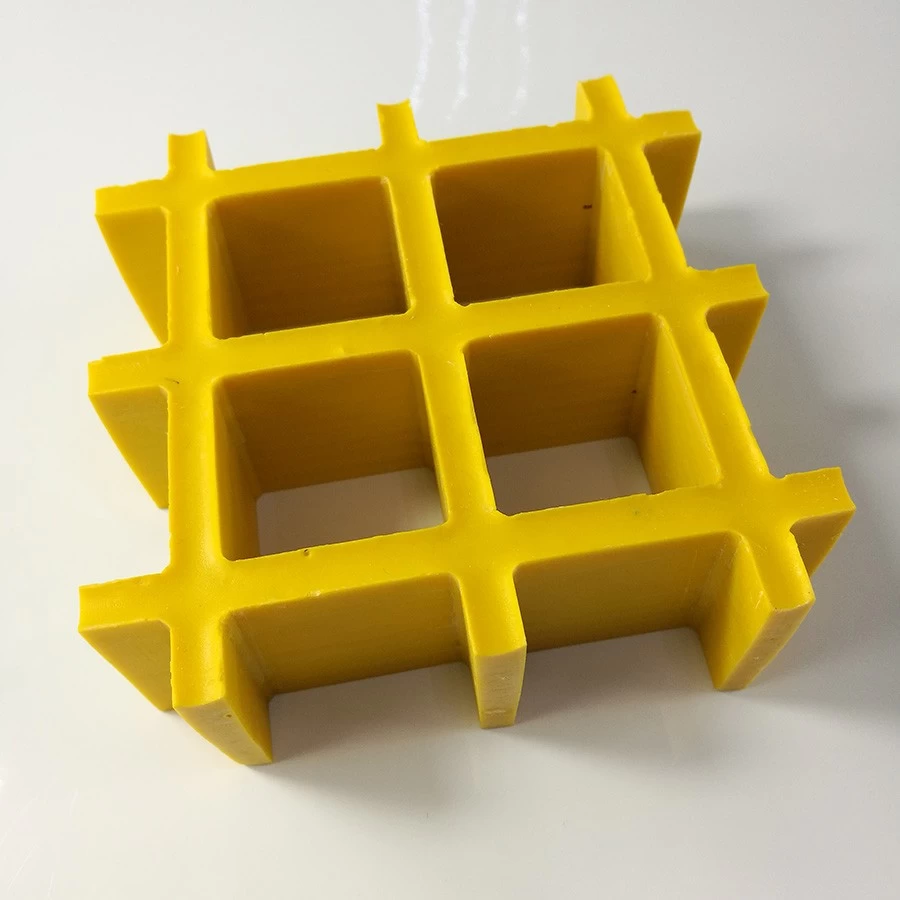

Thanks of the excellent properties of FRP gratings, they are replacing carbon steel, stainless steel, wood and non-ferrous metals. The fiberglass gra...FRP Sheet & Panel Project

Fibre Reinforced Plastic (FRP) Grating Description

The Fibre Reinforced Plastic (FRP) grating is a moulded, one-piece fibreglass reinforced plastic grating, available in standard panels or fabricated i...FORE PP Sheet for Tanks

FORE PP Sheet for Tanks Foreth PP Sheet has good acid and alkali resistance properties,excellent welding processability and non-toxic environmental ...

Decoration Alu Alloy Skin Aluminium Honeycomb Core Composite Sandwich Panels Suppliers

- Use:Outdoor

- After-sale Service:Online technical support, Other

- Warranty:More than 5 years

- Surface Treatment:PE Coated, PVDF Coated

- Function:Anti-static, Fireproof, Mould-Proof

- Feature:Sound Insulation, Light Weight

- Material:Aluminum Alloy

- Size:Customized

- Project Solution Capability:graphic design, 3D model design, Others

- Application:Building Decoration, Partition, furniture

- Design Style:Customized

- Model Number:Aluminium Honeycomb Core Composite Panels

- Thickness:5-100mm

- Width:<2000mm

- Length:<12000mm

- Density:Customized

- Processing Service:Bending, Welding, Cutting, Punching

- Aluminum Alloy Thickness:0.7, 0.8, 1.0mm

- Main market:North America, Europe, southeast Asia, Brazil, etc

- Other Skin:Marble, SPC, HPL, Melamine sheet etc

Decoration Alu Alloy Skin Aluminium Honeycomb Core Composite Sandwich Panels Suppliers

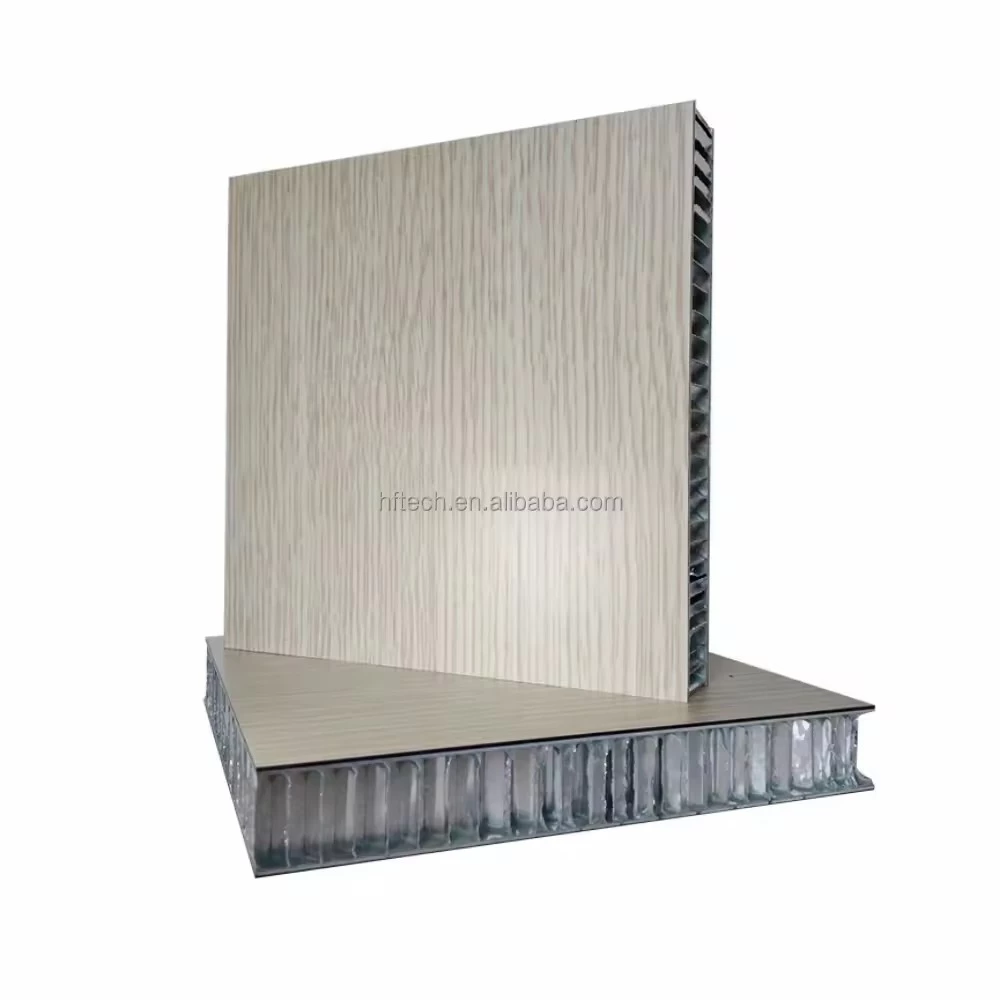

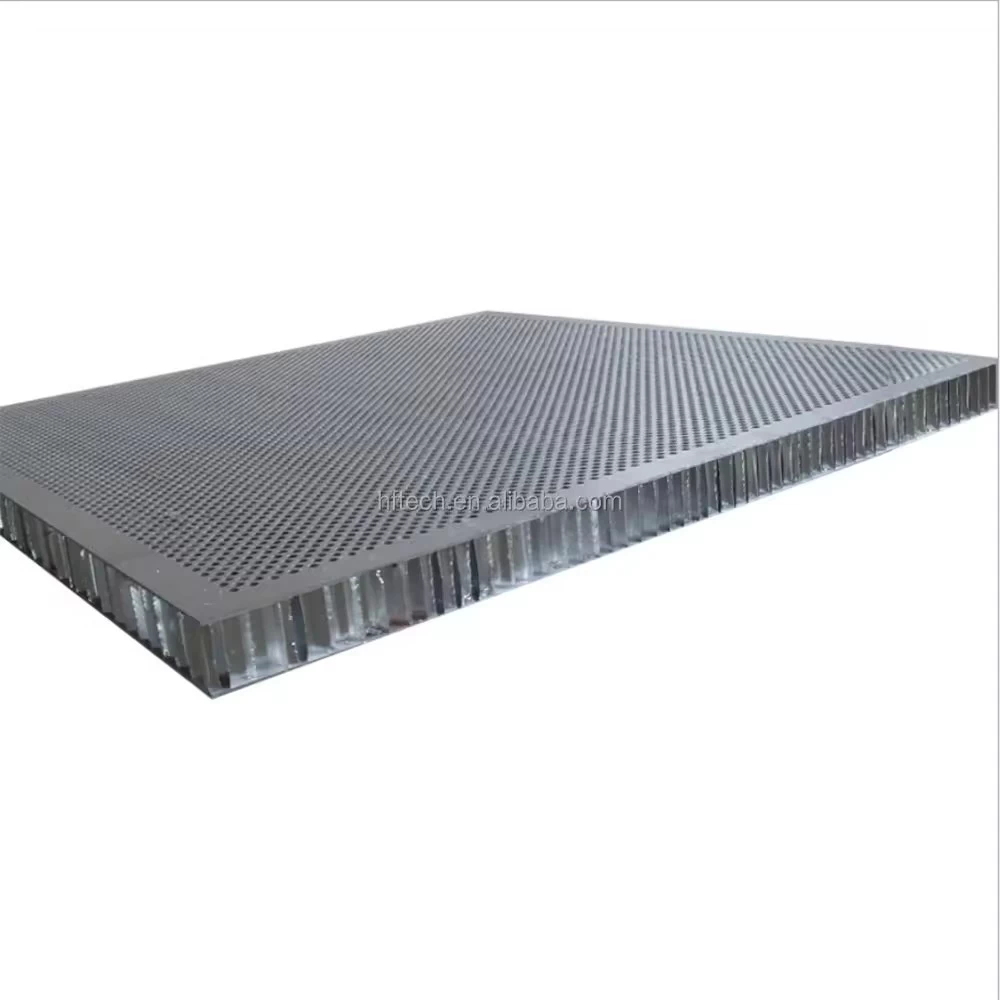

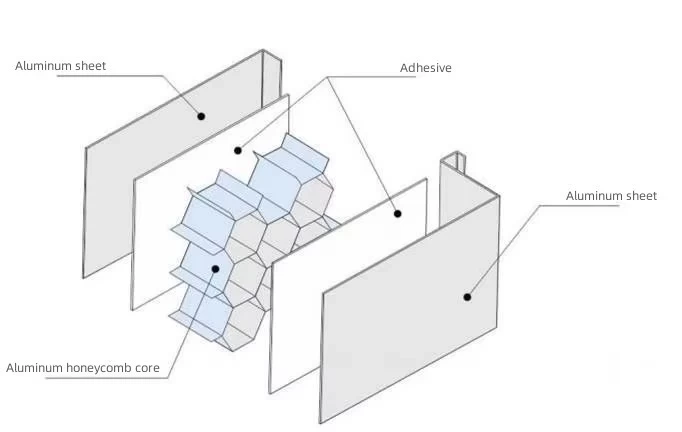

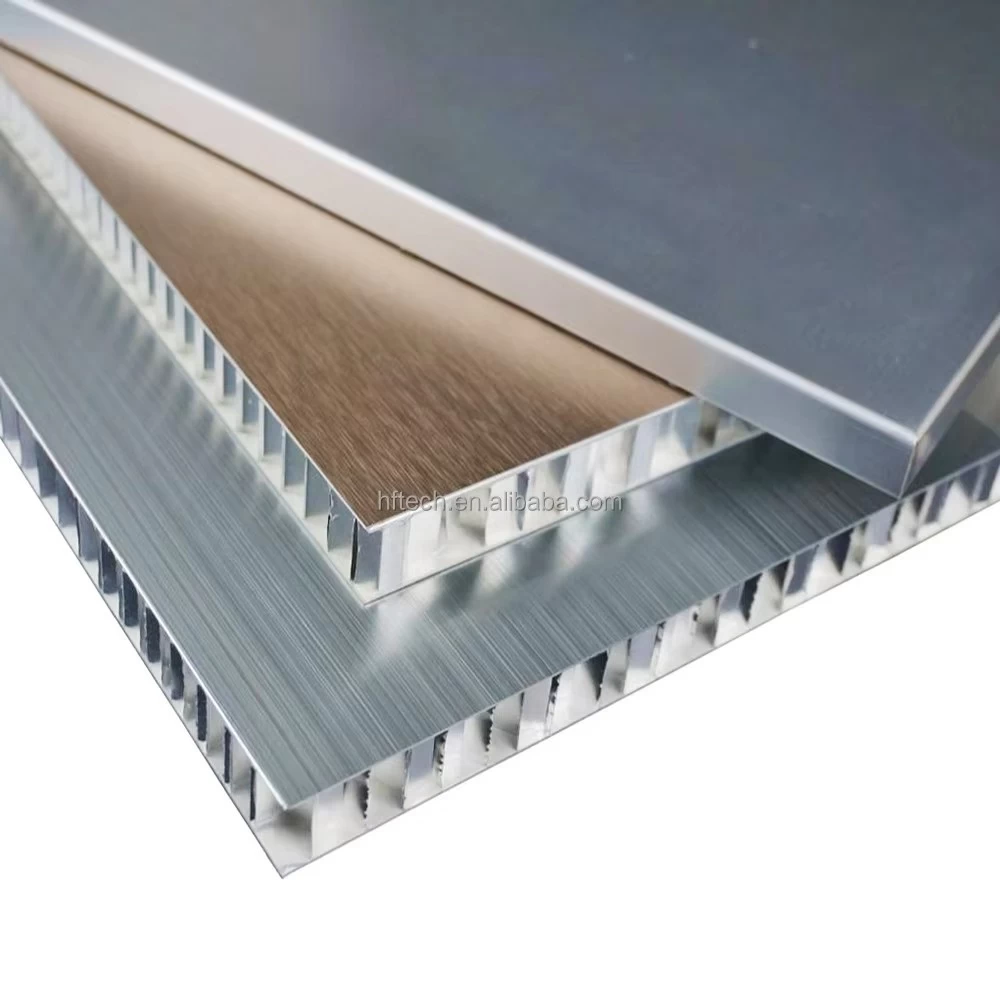

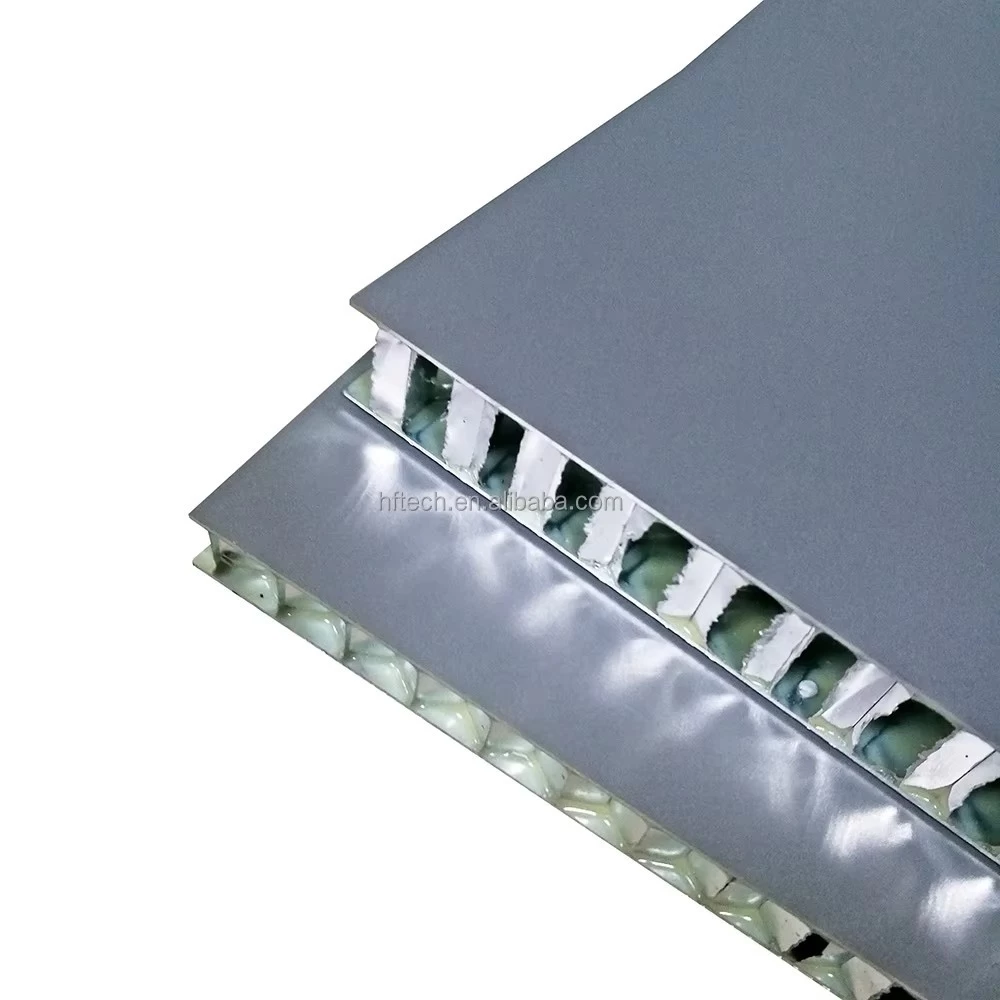

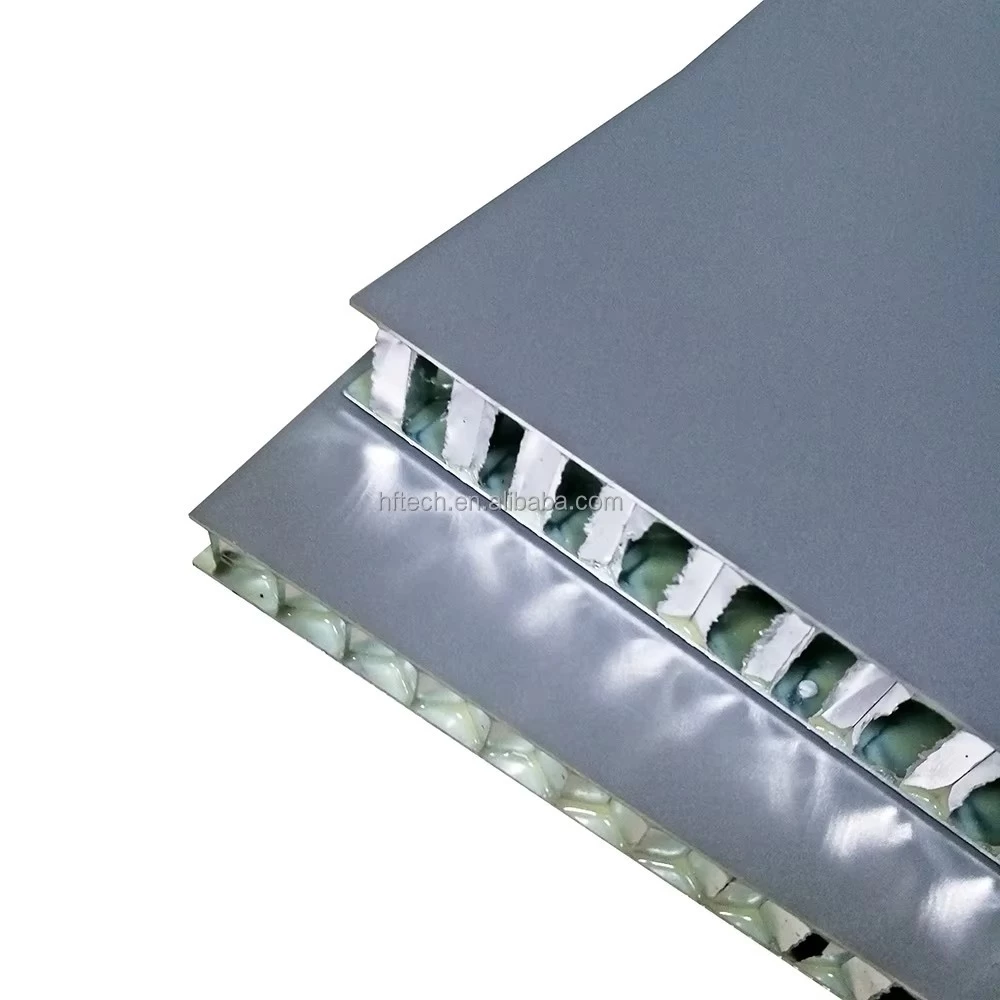

Aluminum Sandwich Panel

The aluminum honeycomb panel is completely made of aluminum material. The surface, bottom plate, and core material are all made of high-strength alloy aluminum. The inner layer is a hexagonal aluminum honeycomb. These

dense honeycombs that contain each other can disperse the pressure from the surface direction. Coat the surface of the aluminum sheet with a thin layer of adhesive to firmly bond the honeycomb core and the upper and lower aluminum sheets together. Hence the honeycomb panel has the advantages of being lightweight, high strength, and good rigidity.

|

A. Introduction

Aluminum Honeycomb Panel is a high-end building decoration material, which is used in the aerospace field with high requirements.

The surface layer of the panel is aluminum alloy plate, and the middle layer is honeycomb structure made of aluminum foil, a lightweight core material, with excellent rigidity. It is currently the best product in metal curtain wall materials. |

|

B. Features

Lightweight, high strength, not easy to deform

Sound insulation, anti-vibration, fireproof and moisture-proof, flame retardant Fungal resistance, resistant to weathering and chemical corrosion Easy to install and maintain Luxurious and beautiful, the finish paint is durable |

|

|

C. Applications

Aluminum Honeycomb panels can be used indoors and outdoors. From buildings, elevator walls, amusement park rides, fine art backing and restoration, stone backing panels for thin cut granite and marble, to wide use

in the transportation industry in light rails, yachts, boats, trucks, RV’s & toy haulers. Almost anytime lightweight and strong support is needed, this will fit the bill. |