What materials are used to make the composite panels for RVs and refrigerated trucks?

With the development of cold chain logistics, refrigerated trucks have become crucial equipment for ensuring the quality of refrigerated transport of goods such as food and pharmaceuticals. A key element in achieving efficient thermal insulation in refrigerated trucks is the application of fiberglass composite panels.

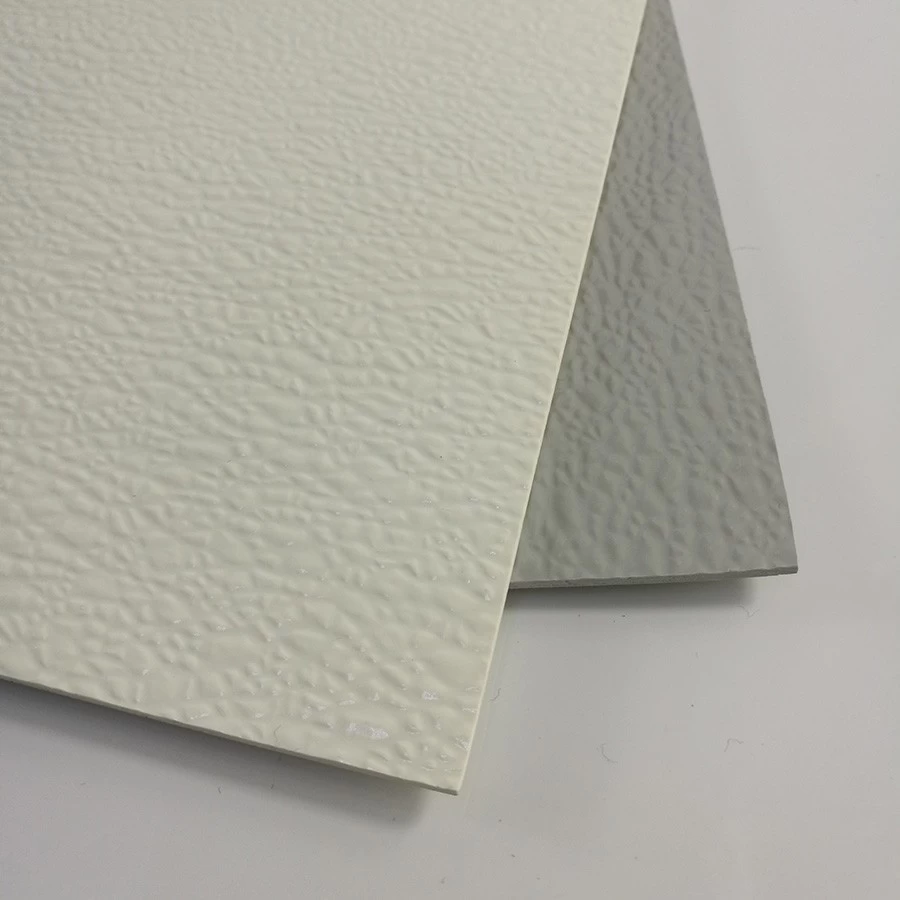

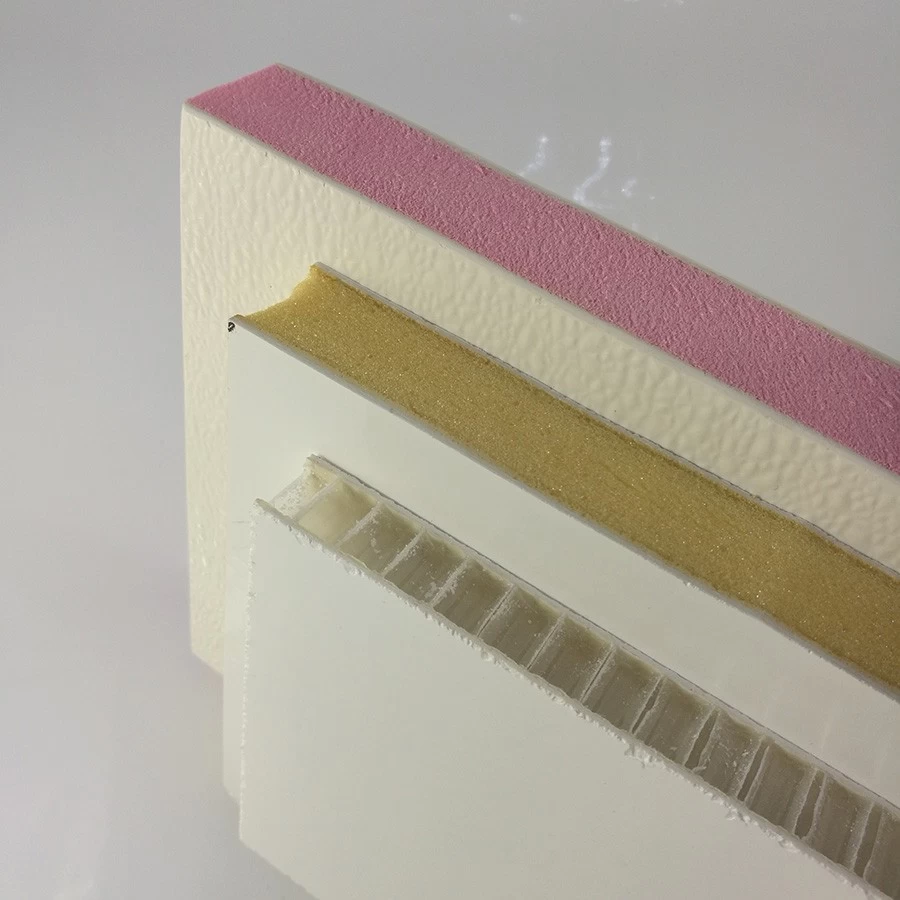

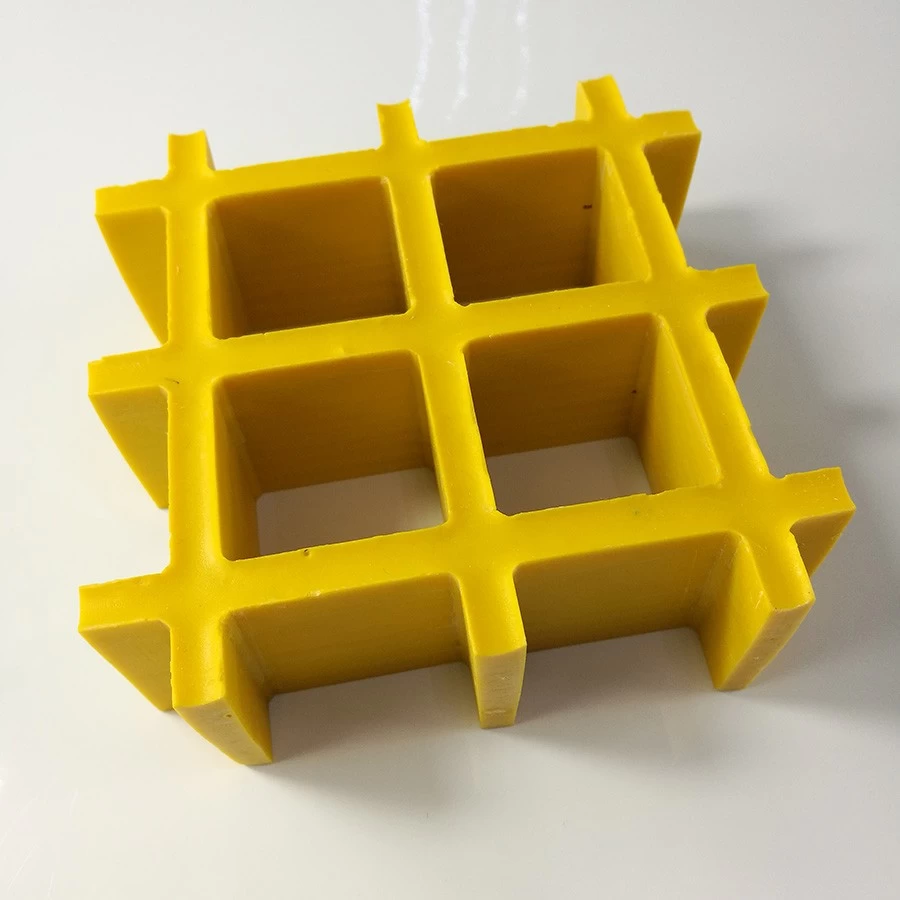

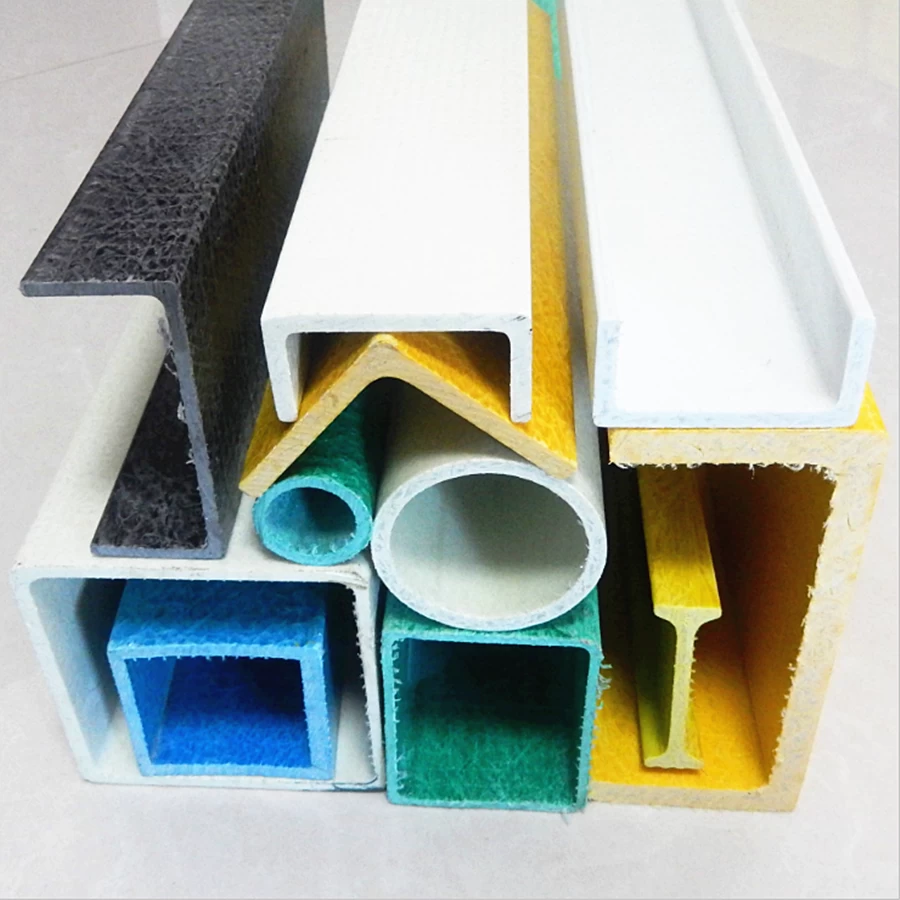

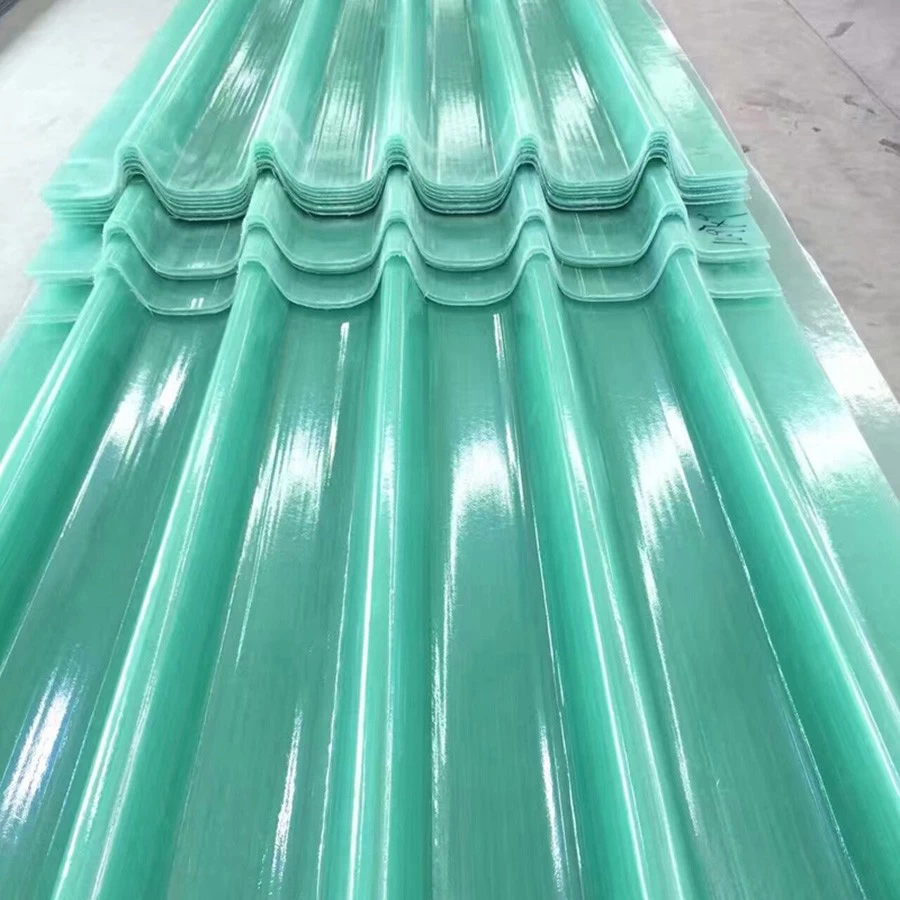

FRP (fiberglass reinforced plastic) composite panels: Utilizing a sandwich structure, the outer layer is an FRP sheet, with a polyurethane foam layer (50-100mm thick) in the middle. They offer advantages such as high and low temperature resistance, excellent thermal insulation, and lightweight construction, making them a mainstream international choice.

As a high-quality building material, fiberglass composite panels possess superior performance and multifunctional characteristics. In refrigerated trucks, they play a vital role:

Excellent thermal insulation performance: Fiberglass composite panels have excellent thermal insulation properties, effectively isolating the temperature difference between the inside and outside of the truck. Their superior insulation properties effectively reduce heat conduction, ensuring a stable low-temperature environment inside the truck, thereby protecting the quality and safety of the goods.

Lightweight and durable: Fiberglass composite panels are lightweight and high-strength, providing excellent structural support and seismic performance, ensuring the stability and safety of the refrigerated truck during operation.

Corrosion and Water Resistance: Fiberglass composite panels possess excellent corrosion resistance, resisting humid environments and chemical corrosion, ensuring a long service life for the truck compartment. Simultaneously, their superior waterproofing effectively prevents moisture penetration, avoiding moisture damage and spoilage of goods.

Easy and Quick Installation: Fiberglass composite panels are prefabricated, with precise dimensions and easy assembly, enabling rapid completion of interior construction, reducing vehicle downtime, and improving work efficiency.

In conclusion, fiberglass composite panels play a vital role in refrigerated truck compartments, providing a reliable solution for ensuring the refrigerated transport of goods. Their excellent thermal insulation performance, lightweight durability, corrosion and water resistance, and convenient installation make them an ideal choice for thermal insulation in refrigerated truck compartments.