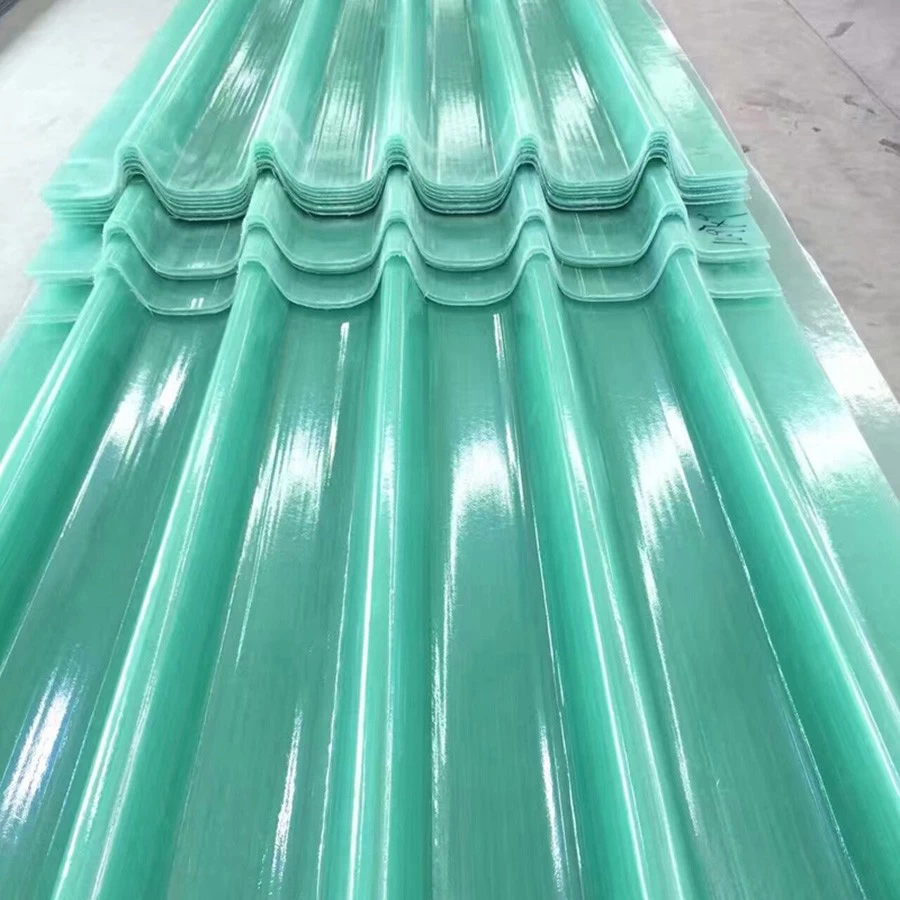

FRP wall panels, interior wall decorative panels

FRP wall panels, interior wall decorative panels

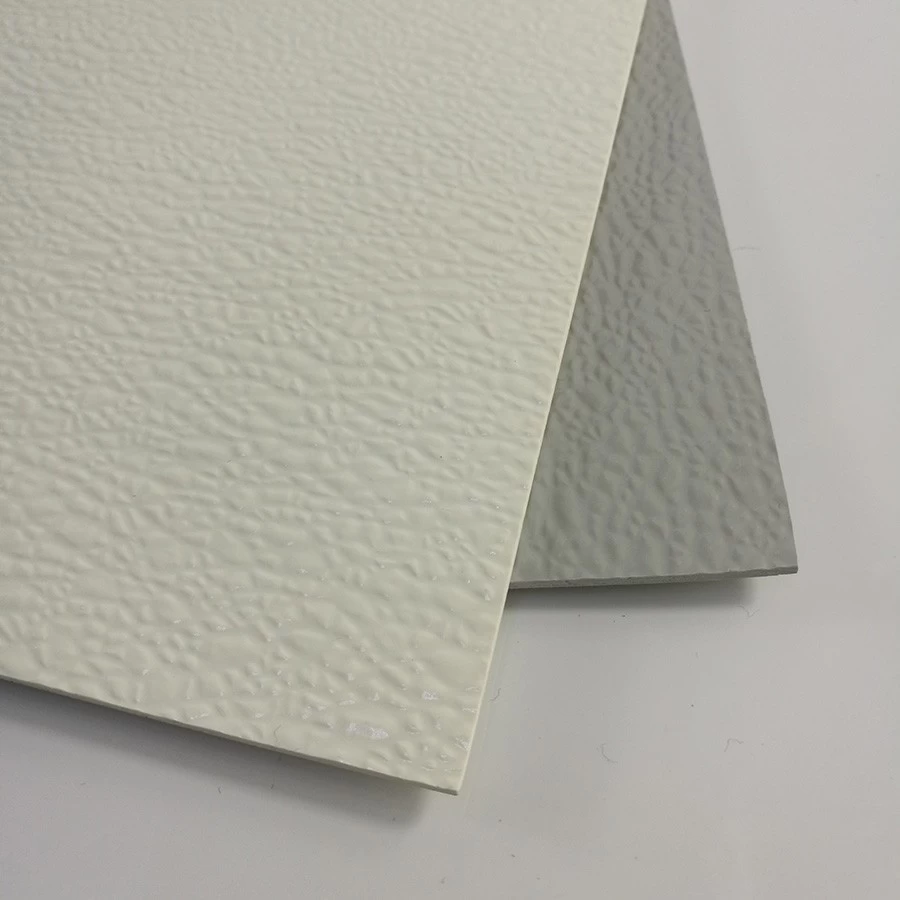

Fiberglass decorative panels, interior wall panels, clean panels, wall skirts, ceilings

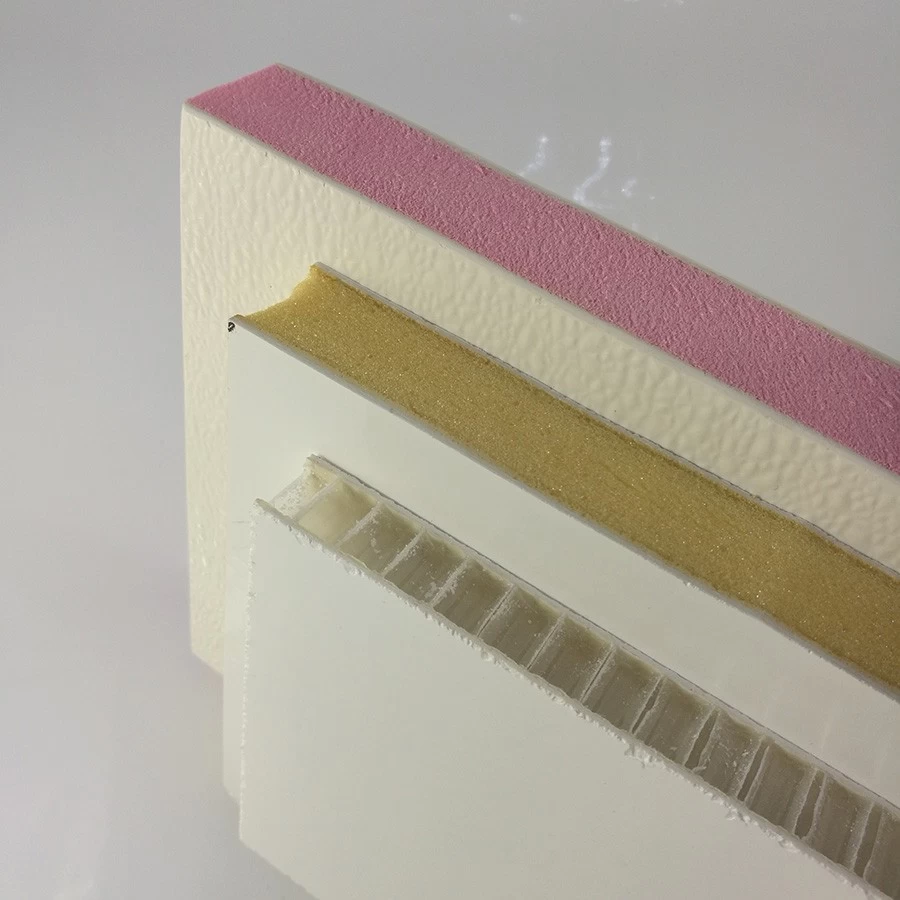

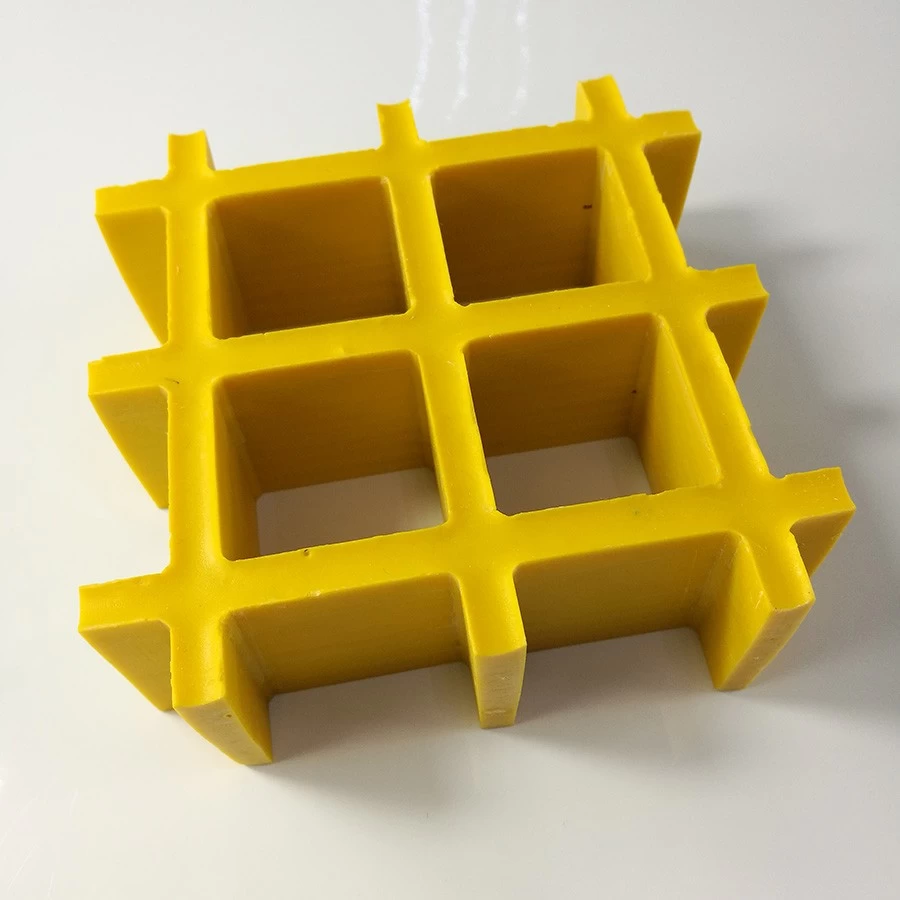

As interior wall and ceiling materials, FRP flat panels do not contain harmful substances, are moisture-proof, mildew-proof, scratch-resistant, easy to clean, resistant to chemical corrosion, and effectively reduce virus attachment. They are very suitable for places with high hygiene requirements and need to be constantly cleaned and maintained. Such as: the interior walls of hospital operating rooms, wards, precision electronic equipment workshops, laboratories, kitchens, slaughterhouses, cold storage rooms, dairies, bakeries, food stores, schools, camps, bathrooms, etc.

In harsh environments such as corrosive gases, water mist and long-term humidity, choosing FRP flat panels and Case panels (FRP stone grain panels) as wall panels can be said to be the only correct solution!

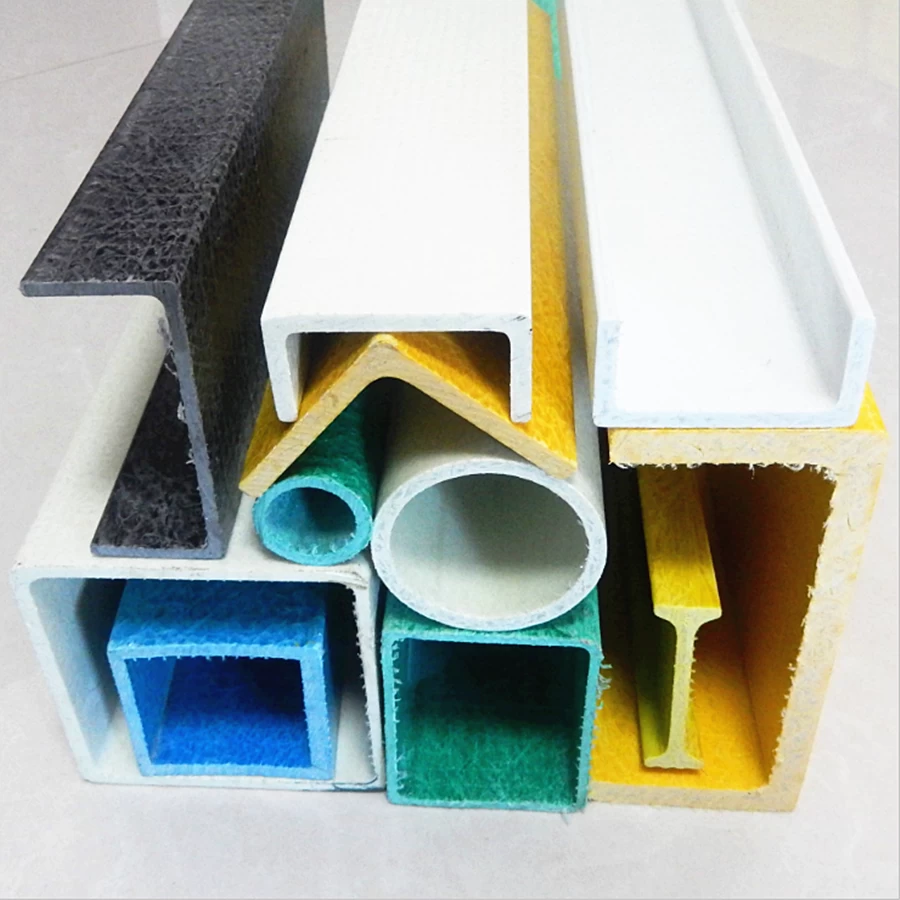

FRP flat panels are used as interior wall decorative panels. Features:

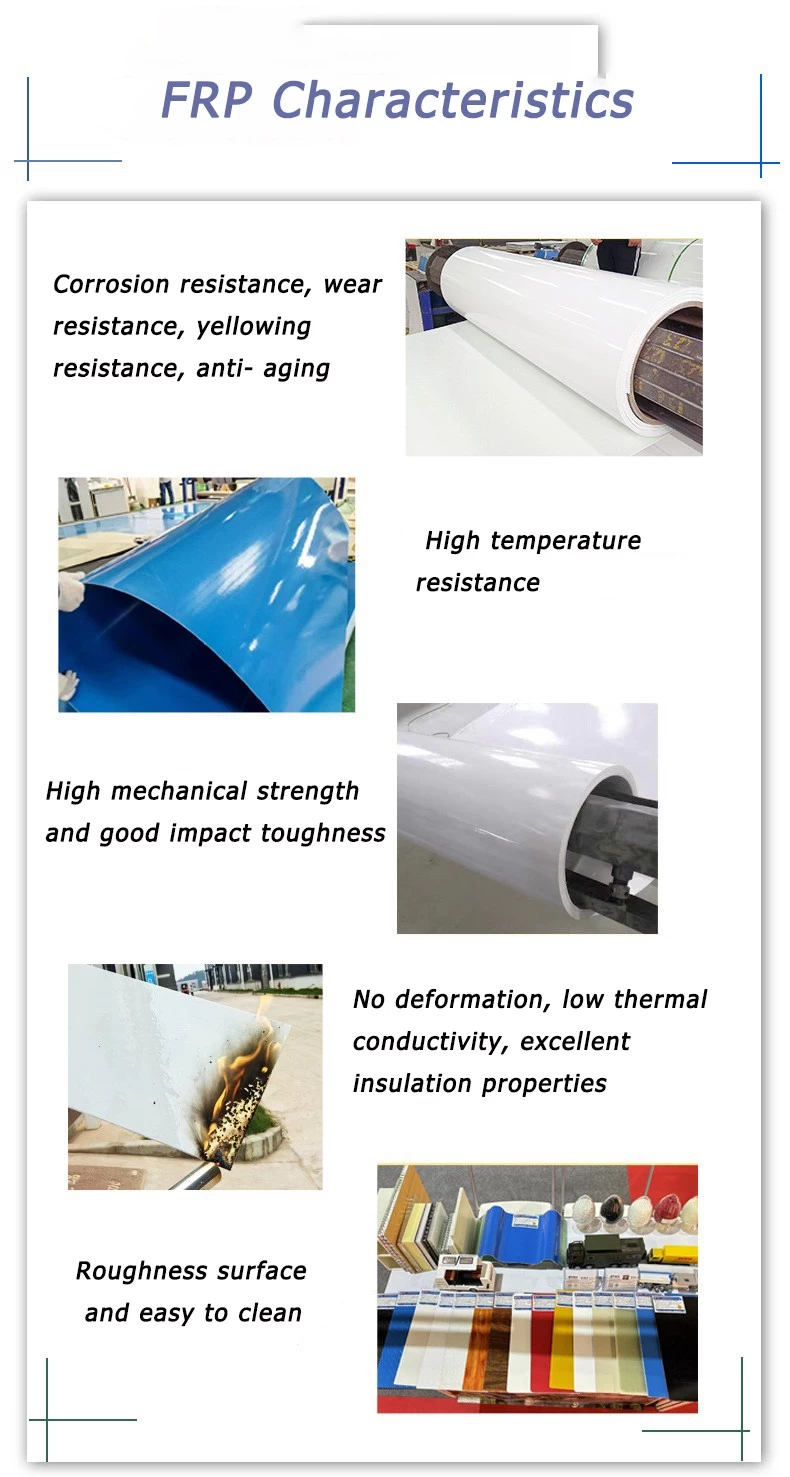

(1) Temperature resistance: long-term use temperature is -30℃~90℃

(2) Corrosion resistance: acid, alkali and salt spray corrosion resistant, can be cleaned with high-pressure water gun or steam

(3) Impact resistance: has the characteristics of engineering plastics

(4) Easy to clean: the gel coat surface has lotus leaf-like self-cleaning properties

(5) Environmentally friendly, mildew-proof and antibacterial

(6) Easy to install: can use rivets or glue, no special tools are required

(7) Flame retardant: flame retardant panels, oxygen index can reach more than 30

Flat curtain wall installation instructions:

No special tools are required for cutting FRP gel coat flat panels. A simple electric saw is enough to cope with large-scale installation and construction. It can be directly attached to the wall, ceiling, or even tiles.

1. Common installation process

① Use profiles to simplify the installation process;

② The edges of adjacent panels must be fixed with rivets in an alternating manner;

③ This process must be used in humid environments;

④ When sealing the edges, the edges of the panels are sealed with glass glue to prevent water mist from entering the gap between the panels and the wall.

2. Adhesive sticker installation

① Make sure the wall is free of grease, dirt, and dust, and polish it flat;

② The glue must be applied vertically to prevent dust from accumulating on the glue;

③ In a humid environment, the adhesive sticker process cannot be used;

④ When sealing the edges, the edges of the board should be sealed with glass glue to prevent water mist from entering the gap between the board and the wall.