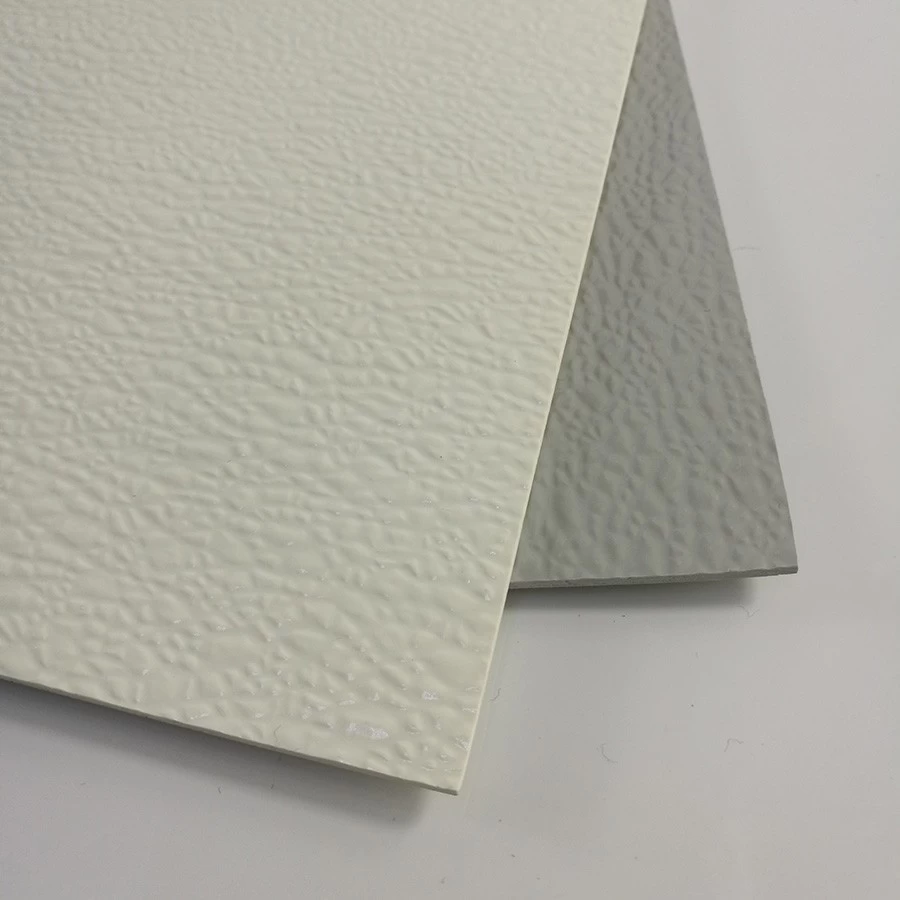

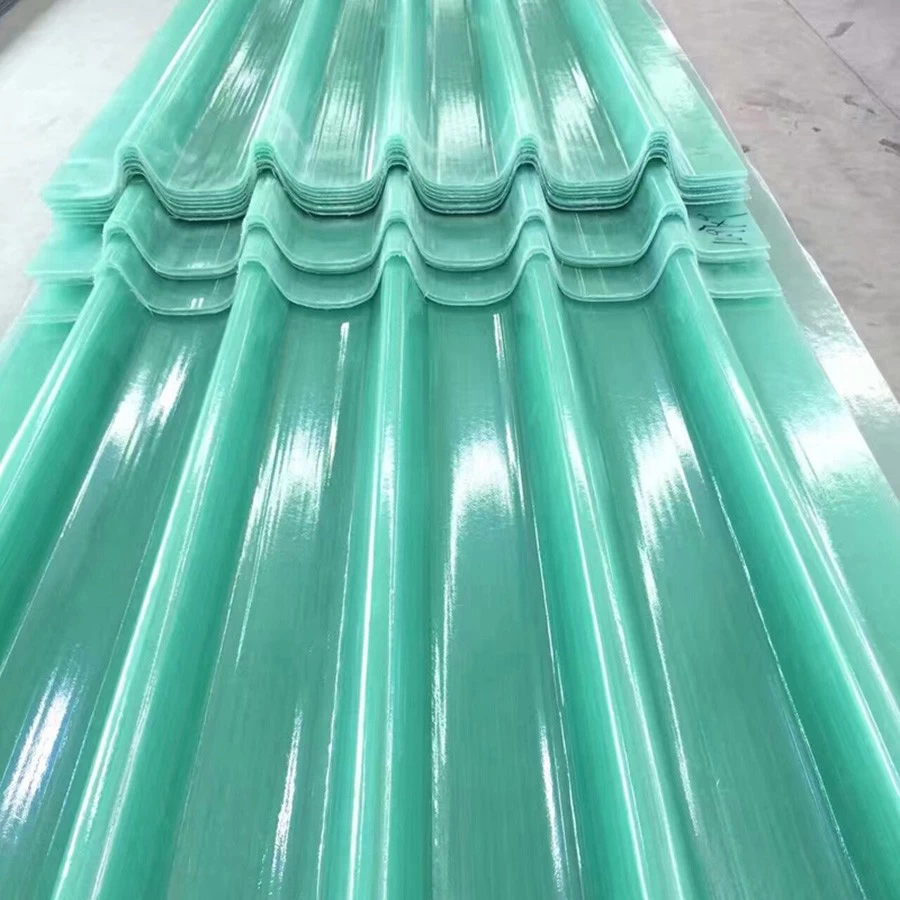

FRP panels characteristics and applicable scenarios

FRP panels (fiber reinforced composite panels) are mainly used in the fields of lighting, structural support and protection in buildings. Their characteristics and applicable scenarios are as follows:

Lighting applications

The light transmittance of FRP lighting panels can reach 87%-89%, which is close to glass but more weather-resistant. It is suitable for roof lighting in industrial plants, commercial buildings and civil buildings. Its impact resistance is 2-20 times that of tempered glass. Its weather resistance can block ultraviolet rays and keep the light soft. During installation, the panel type can be customized according to needs to match the roof structure.

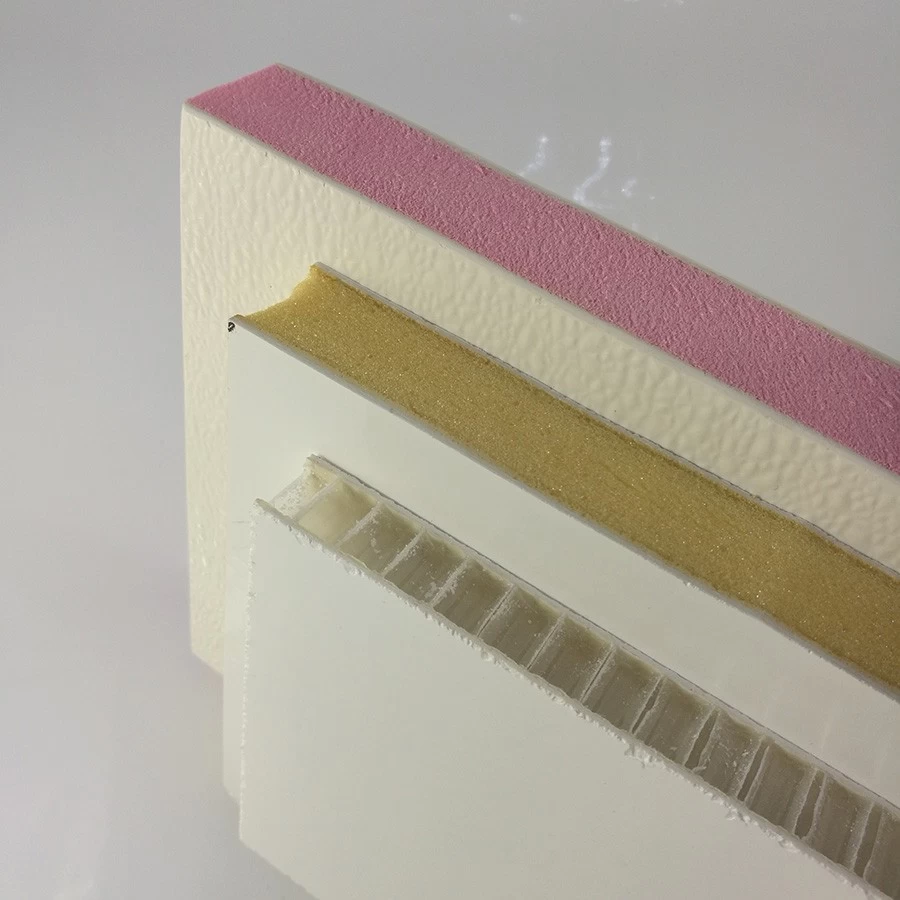

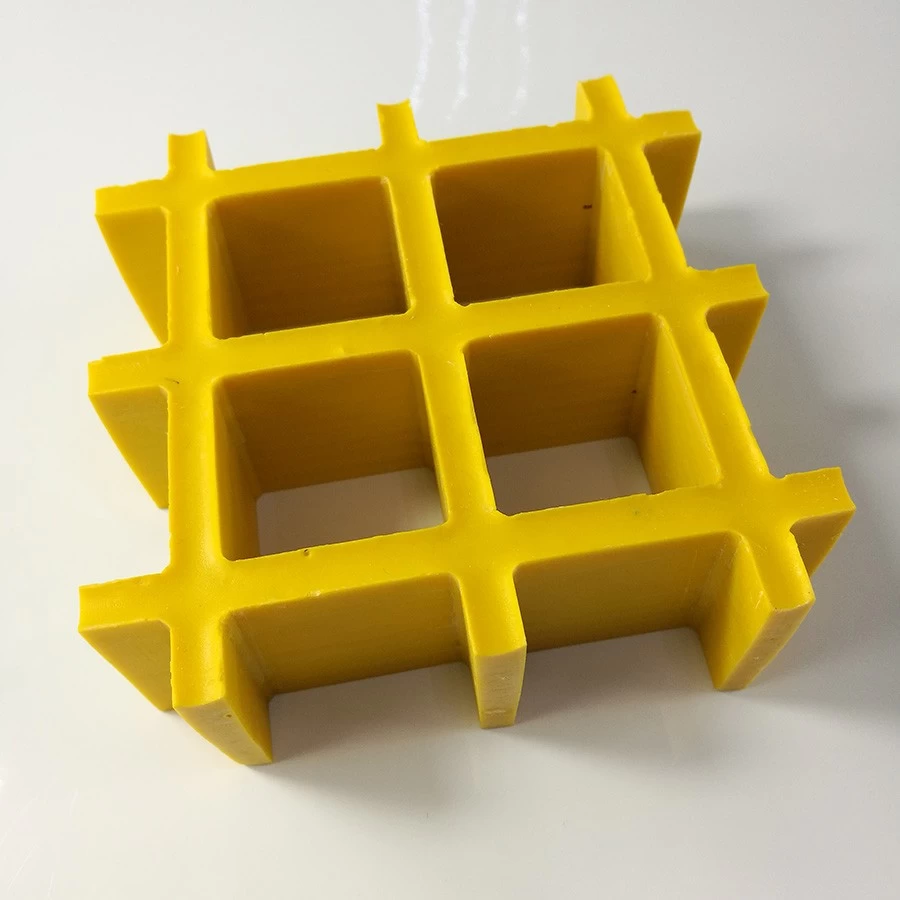

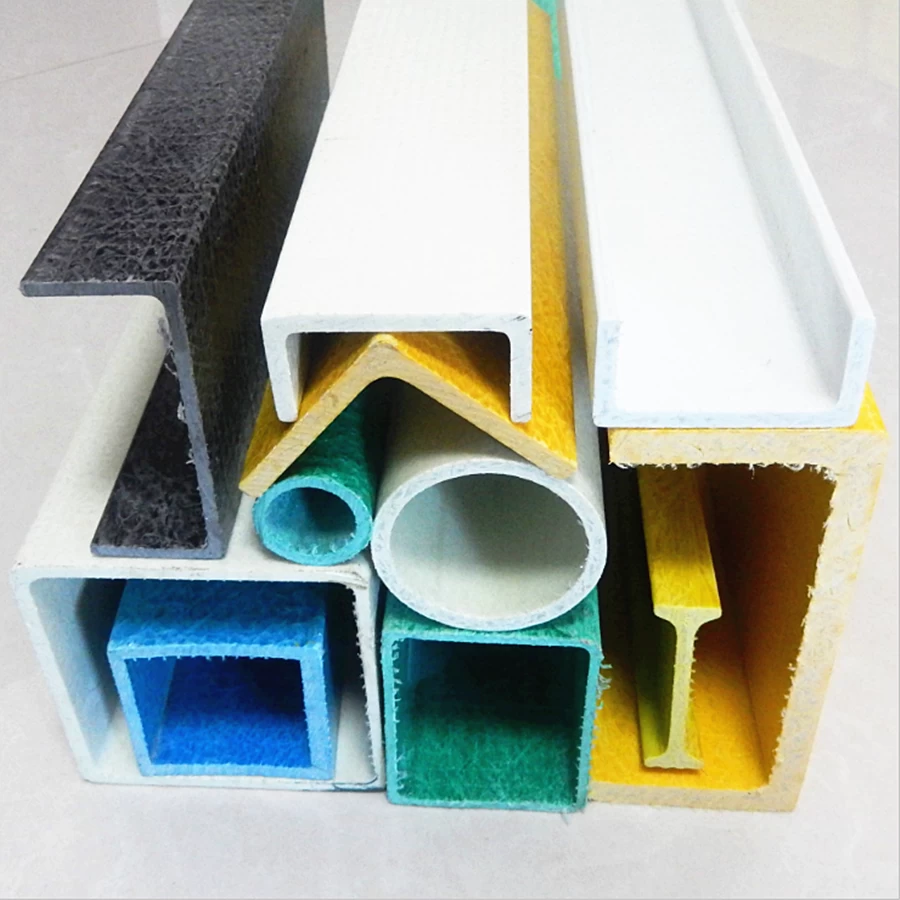

Structural support

FRP materials are light and corrosion-resistant. They are often used in structural components such as bridges, guardrails, and air-conditioning brackets. They have both strength and durability. For example, the use of FRP materials in structural elements such as bridge decks, columns, and beams can reduce weight and improve safety.

Protective use

FRP panels are resistant to acid and alkali corrosion and are suitable for anti-corrosion needs in corrosive environments such as chemical plants and sewage treatment plants. Its surface can be customized with anti-aging coating, with a service life of up to 20 years. Some models have flame retardant properties, no melting dripping in fire and reduced smoke generation.

Development trend

In the future, FRP sheets will focus more on customized production, developing products with high light transmittance (close to glass) and higher impact resistance. Application scenarios will be expanded to more civil building facades and large-span structures, replacing traditional building materials to achieve a balance between lightweight and durability.