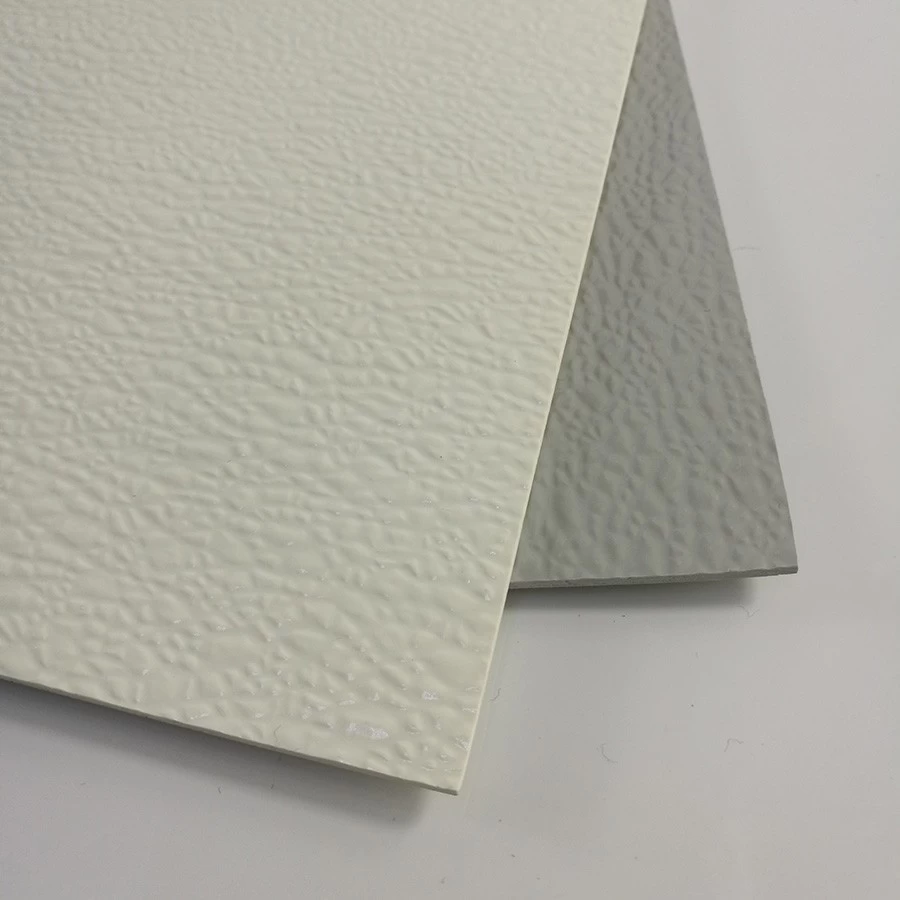

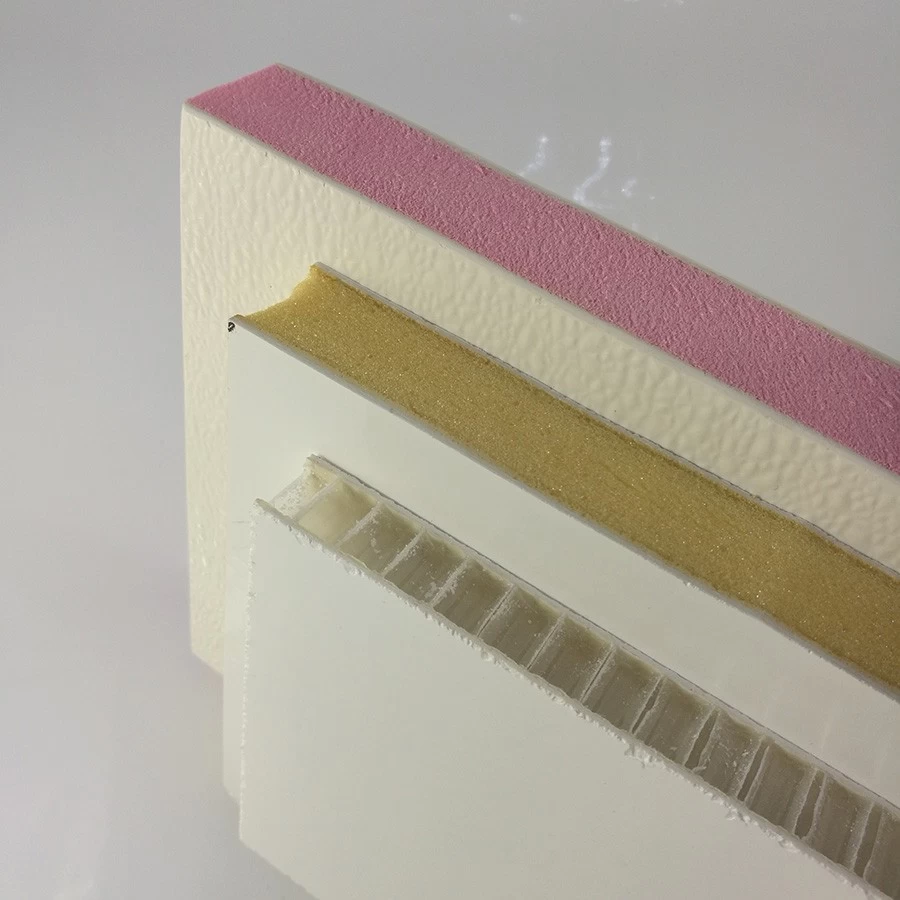

Due to cost, installation and construction, the refrigerated truck van panels were gradually made of FRP composite panels. FRP composite panels are made of FRP flats and used as two layers of the bottom and the top, in addition to the role of controlling the weight, and also have good impact resistance. The middle layer uses different kinds of core materials, such as PP honeycomb core material, XPS core material, PU core material, etc.,

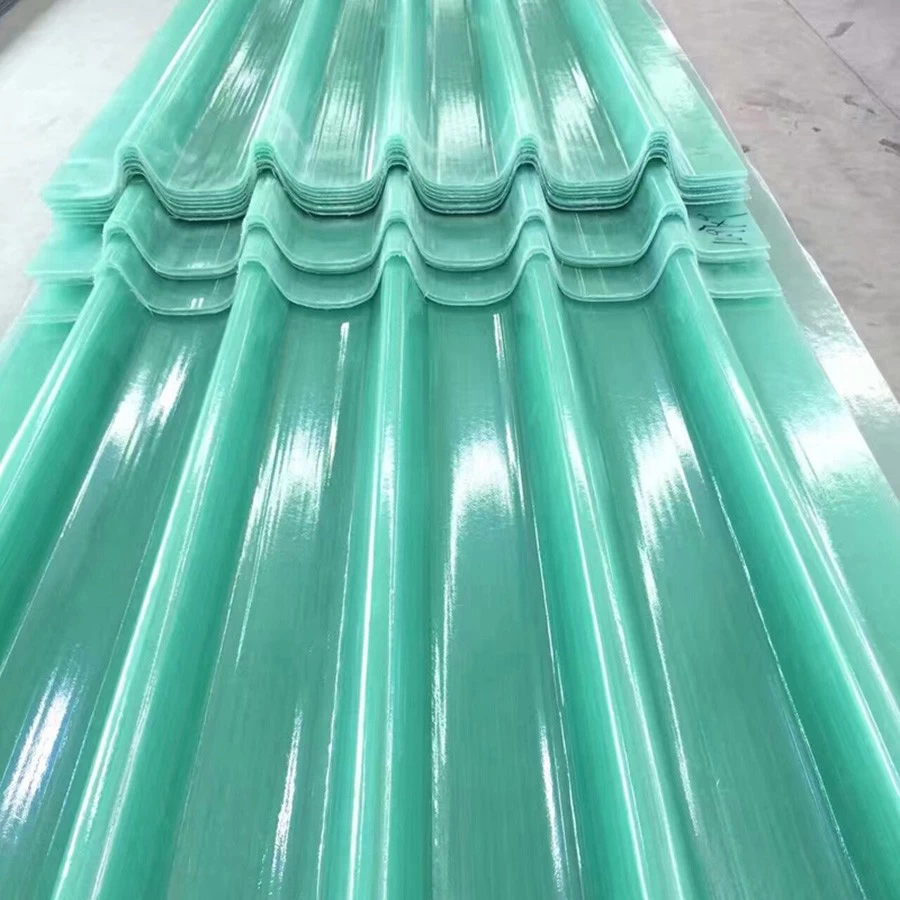

At the beginning of the industry, manpower was usually used to make FRP, but most manufacturers use production line to produce FRP sheet now. FRP mechanism sheet gradually replaced hand lay-up sheet. The FRP mechanism sheet has many advantages over the hand lay-up. The FRP mechanism plate has stable quality and uniform thickness. Cost-effective, neat and shiny surface.

1) Hydroponic OverviewHydroponics is a new type of plant soilless culture method, also known as nutrient solution culture. Its core is to directly inf...

ABS sheet is an emerging material in the plastic sheet industry. The full name is Acrylonitrile butdiene styrene. It is a polymer with a relatively la...

A, Fire-retardant FRP lighting roofing panels are mainly used in steel mills and blast furnaces with high temperatures, fire point splashes or some sp...

Do you know what a RV is? The concept of the beginning of RV is “movable house”. The RV has all the necessary items for life, including bedr...

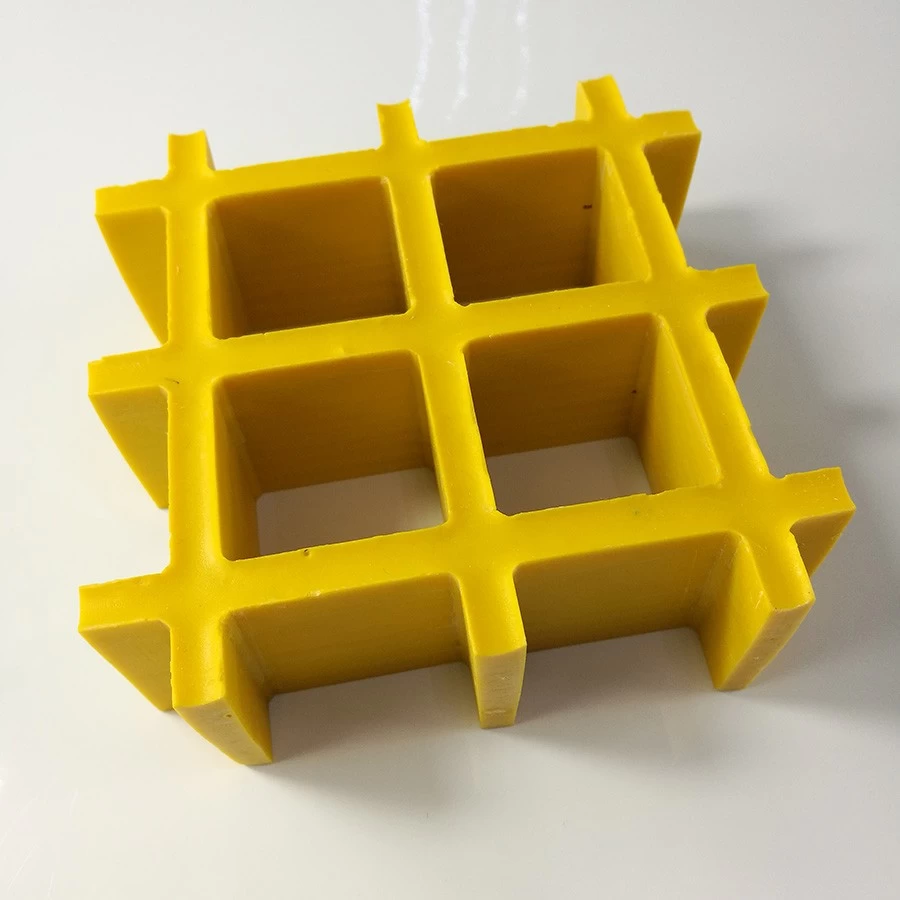

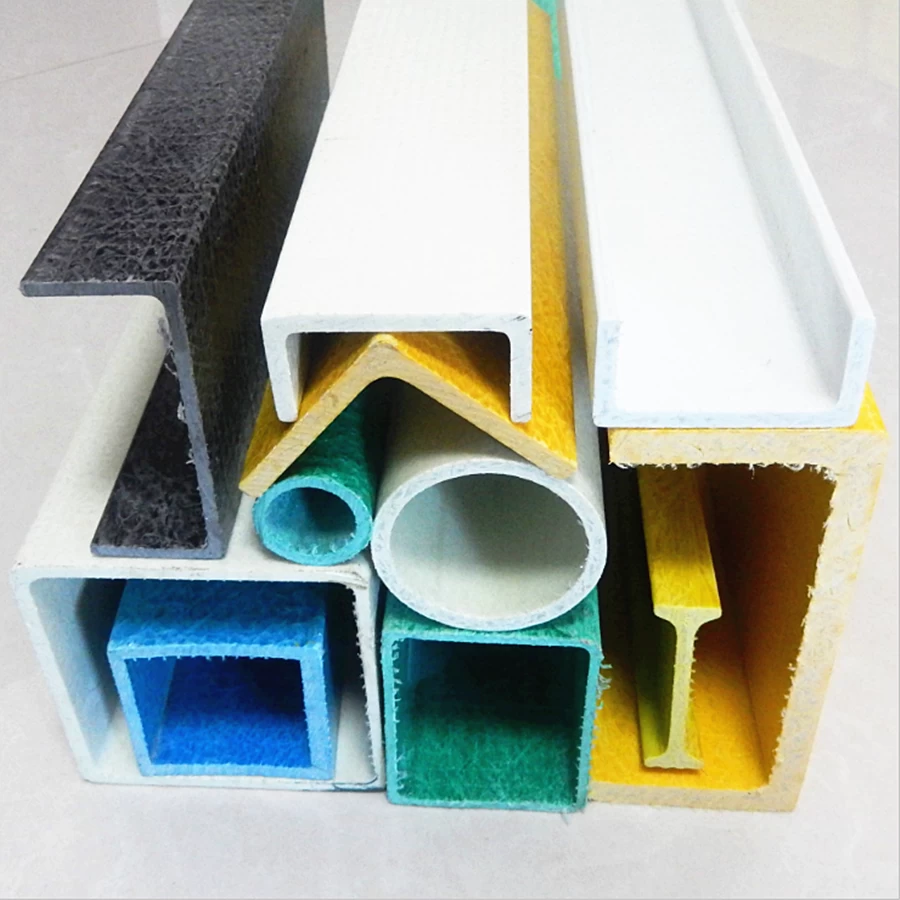

Thanks of the excellent properties of FRP gratings, they are replacing carbon steel, stainless steel, wood and non-ferrous metals. The fiberglass gra...

The Fibre Reinforced Plastic (FRP) grating is a moulded, one-piece fibreglass reinforced plastic grating, available in standard panels or fabricated i...

FORE PP Sheet for Tanks Foreth PP Sheet has good acid and alkali resistance properties,excellent welding processability and non-toxic environmental ...