- Browse Categories

- FRP Product

- FRP Sheet

- FRP Panel

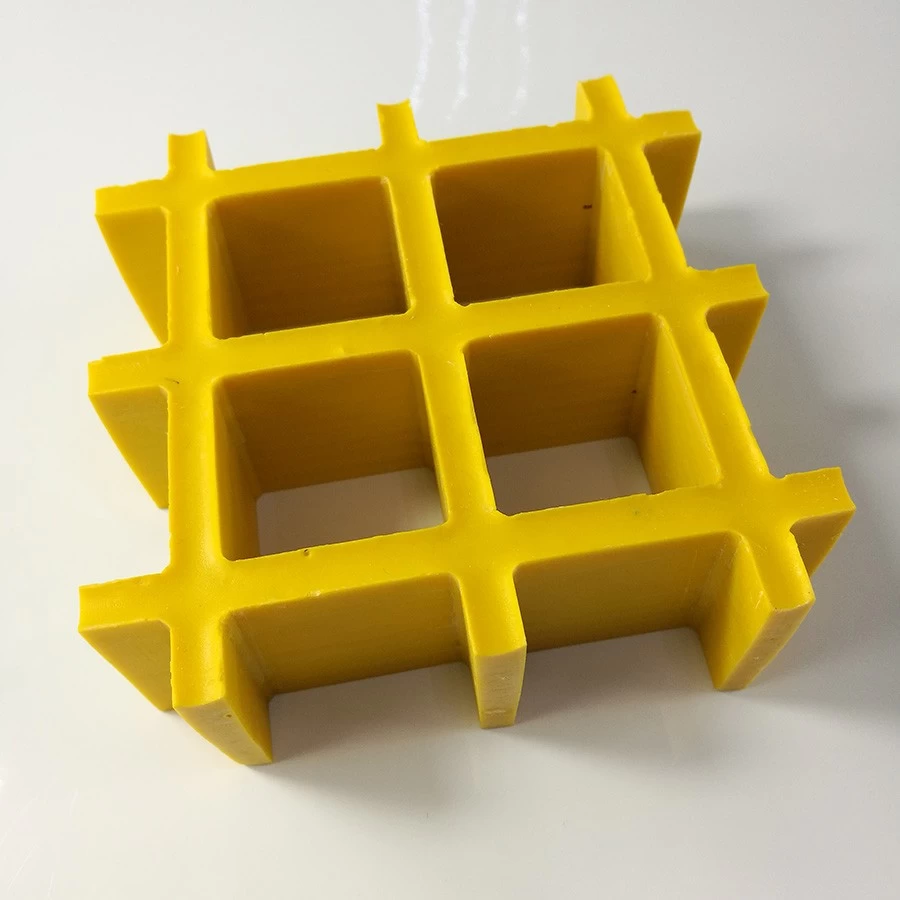

- FRP Grating

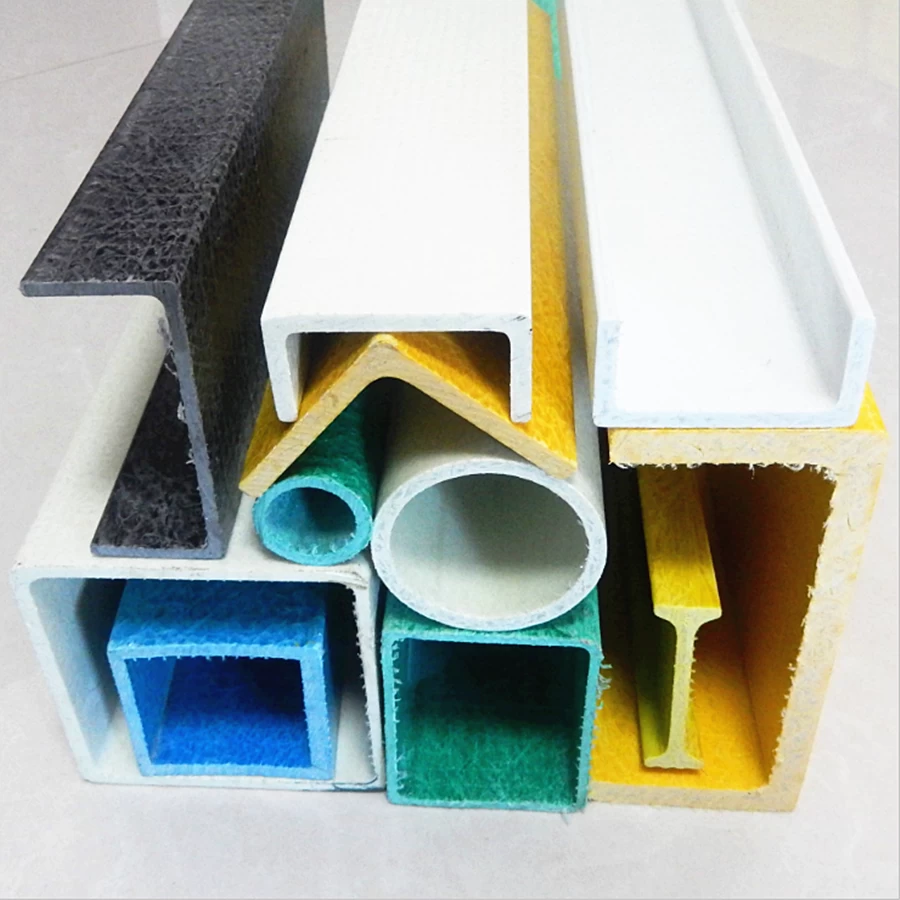

- FRP Profiles

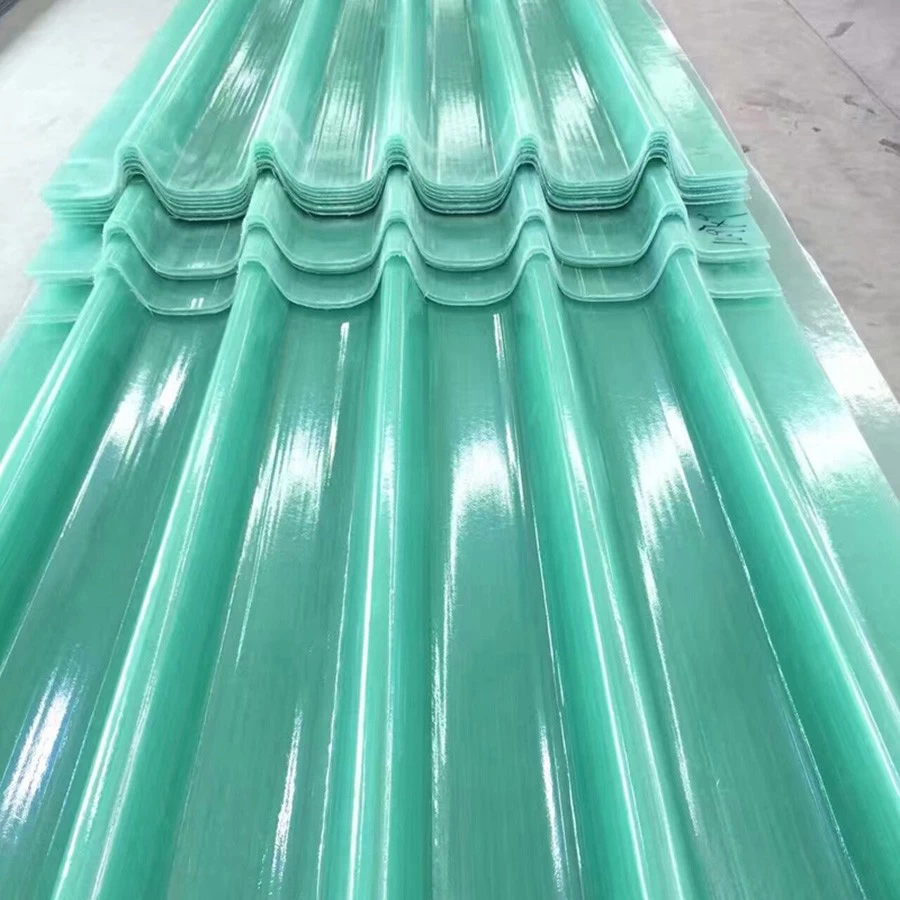

- FRP Roofing Sheet

- FRP Manhole Cover

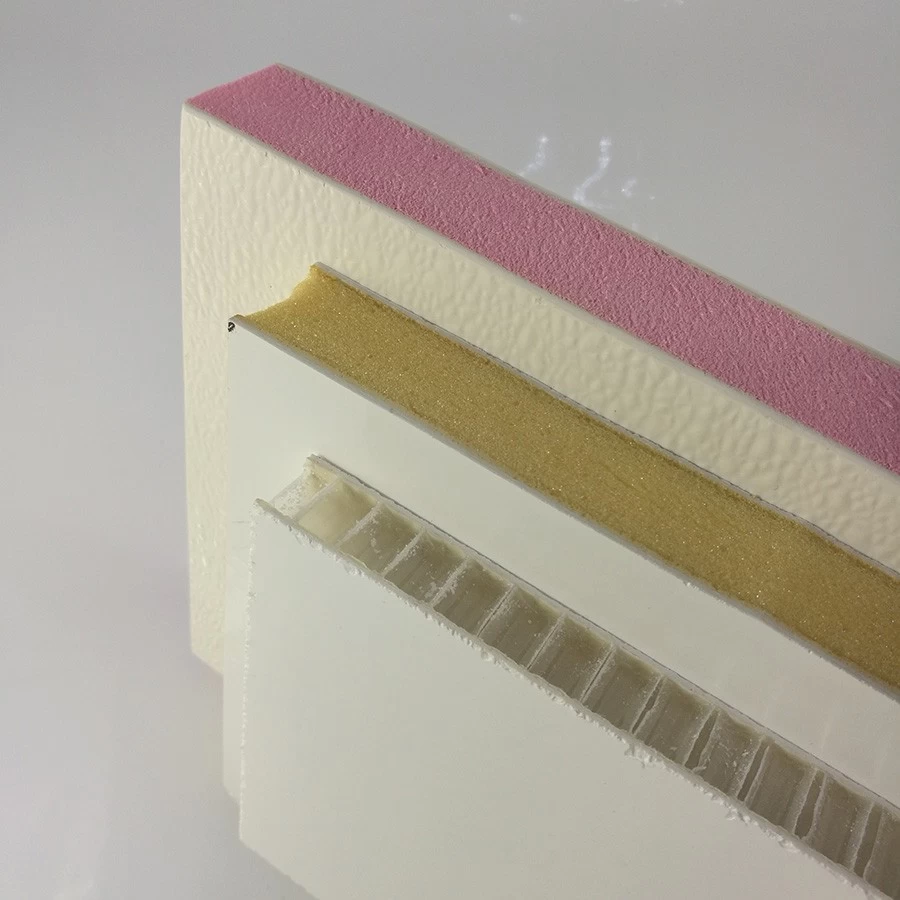

- FRP Sandwich Panel

- Plastic Product

- Subscribe

-

Get email updates on new products

- Contact Us

-

Telephone: +86-0755-28329102

Mobile Phone: +86-15814411453

Fax: +86-755-28998345

Address:Room 02, 32 Floor, 6 block, Phase 3, Xieli Garden, Longcheng Street, Longgang District, Shenzhen

Zip:518172

Country/Region:China (Mainland)

Province/State:Guangdong

City:Shenzhen Contact Now

- FRP Product

- News

-

How to Choose Refrigerated Truck Body Panels

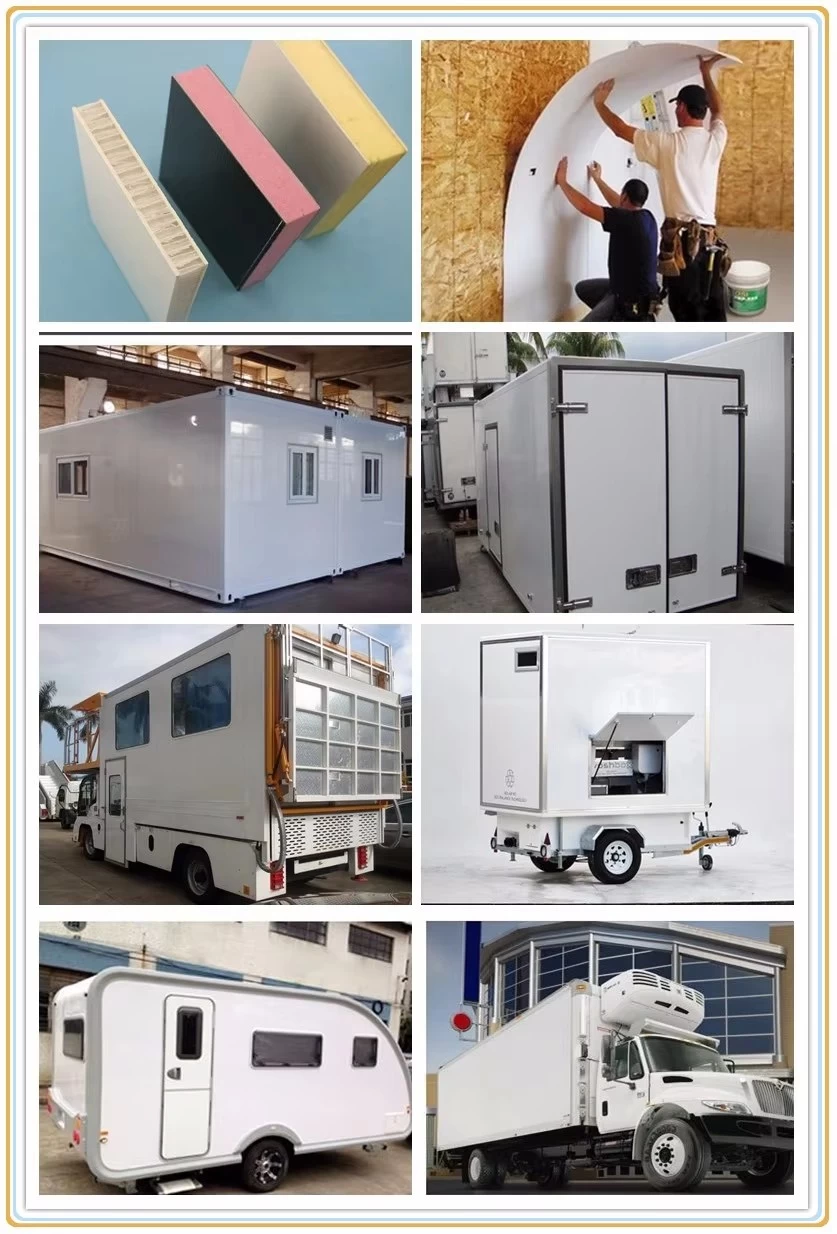

Due to cost, installation and construction, the refrigerated truck van panels were gradually made of FRP composite panels. FRP composite panels are made of FRP flats and used as two layers of the bottom and the top, in addition to the role of controlling the weight, and also have good impact resistance. The middle layer uses different kinds of core materials, such as PP honeycomb core material, XPS core material, PU core material, etc.,The differences between FRP mechanism sheet and Hand Lay-up sheets

At the beginning of the industry, manpower was usually used to make FRP, but most manufacturers use production line to produce FRP sheet now. FRP mechanism sheet gradually replaced hand lay-up sheet. The FRP mechanism sheet has many advantages over the hand lay-up. The FRP mechanism plate has stable quality and uniform thickness. Cost-effective, neat and shiny surface.Hydroponics Overview Technique and Advantages

1) Hydroponic OverviewHydroponics is a new type of plant soilless culture method, also known as nutrient solution culture. Its core is to directly inf...ABS Sheet Performance and Applications

ABS sheet is an emerging material in the plastic sheet industry. The full name is Acrylonitrile butdiene styrene. It is a polymer with a relatively la...Can Flame-retardant Fiberglass Lighting Roofing Panels Be Still Used After Yellowing?

A, Fire-retardant FRP lighting roofing panels are mainly used in steel mills and blast furnaces with high temperatures, fire point splashes or some sp...RV Traveling Are Getting More and More Popular

Do you know what a RV is? The concept of the beginning of RV is “movable house”. The RV has all the necessary items for life, including bedr...FRP Gratings Applications

Thanks of the excellent properties of FRP gratings, they are replacing carbon steel, stainless steel, wood and non-ferrous metals. The fiberglass gra...FRP Sheet & Panel Project

Fibre Reinforced Plastic (FRP) Grating Description

The Fibre Reinforced Plastic (FRP) grating is a moulded, one-piece fibreglass reinforced plastic grating, available in standard panels or fabricated i...FORE PP Sheet for Tanks

FORE PP Sheet for Tanks Foreth PP Sheet has good acid and alkali resistance properties,excellent welding processability and non-toxic environmental ...

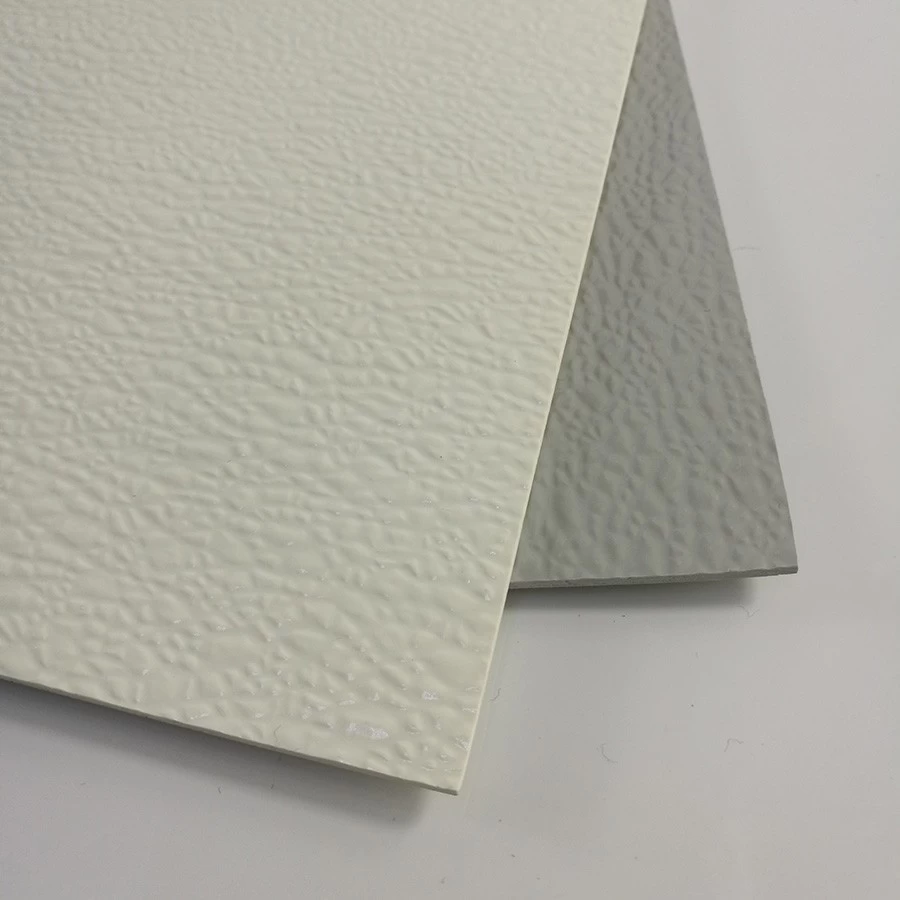

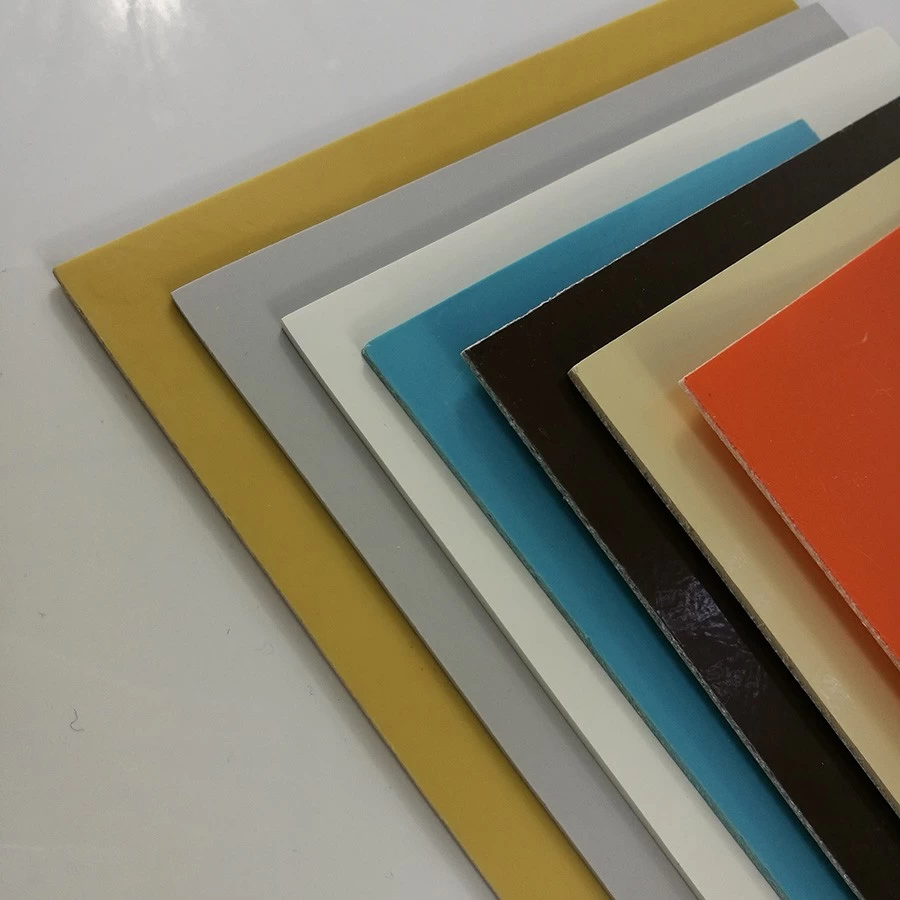

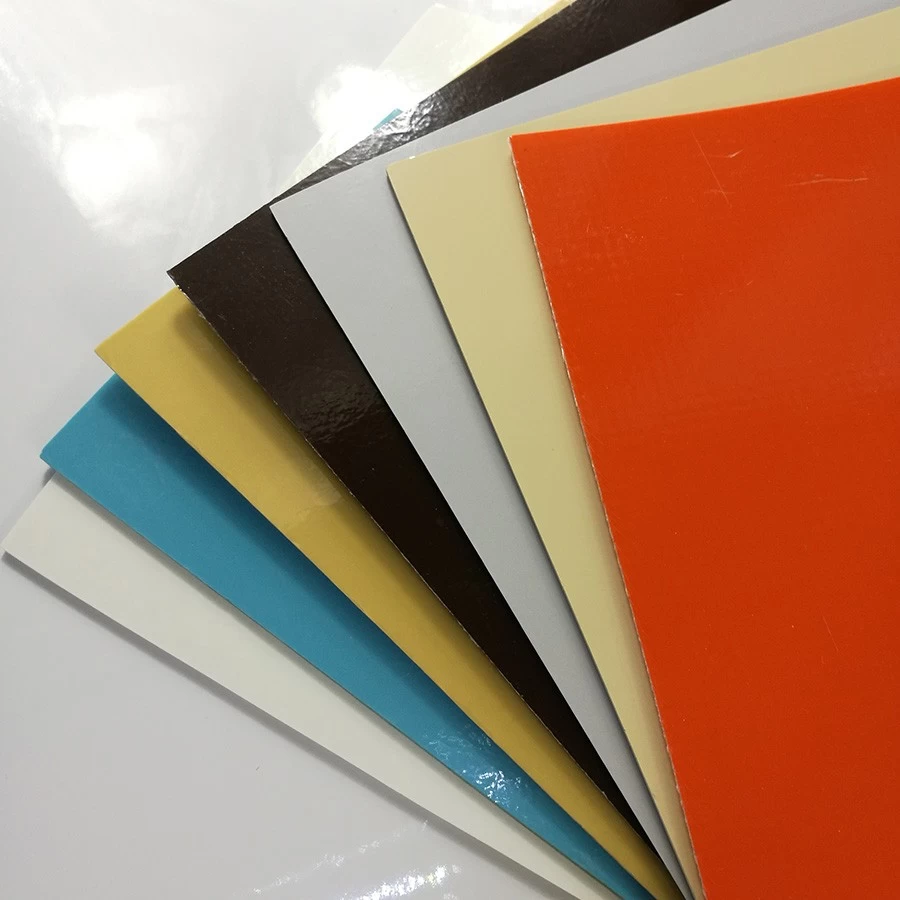

Flat Gelcoat FRP Sheet

- Processing Service:Cutting

- Place of Origin:Guangdong, China

- Brand Name:fore

- Material:FRP

- Size:customized

- Material:Fiberglass Reinforced Plastic

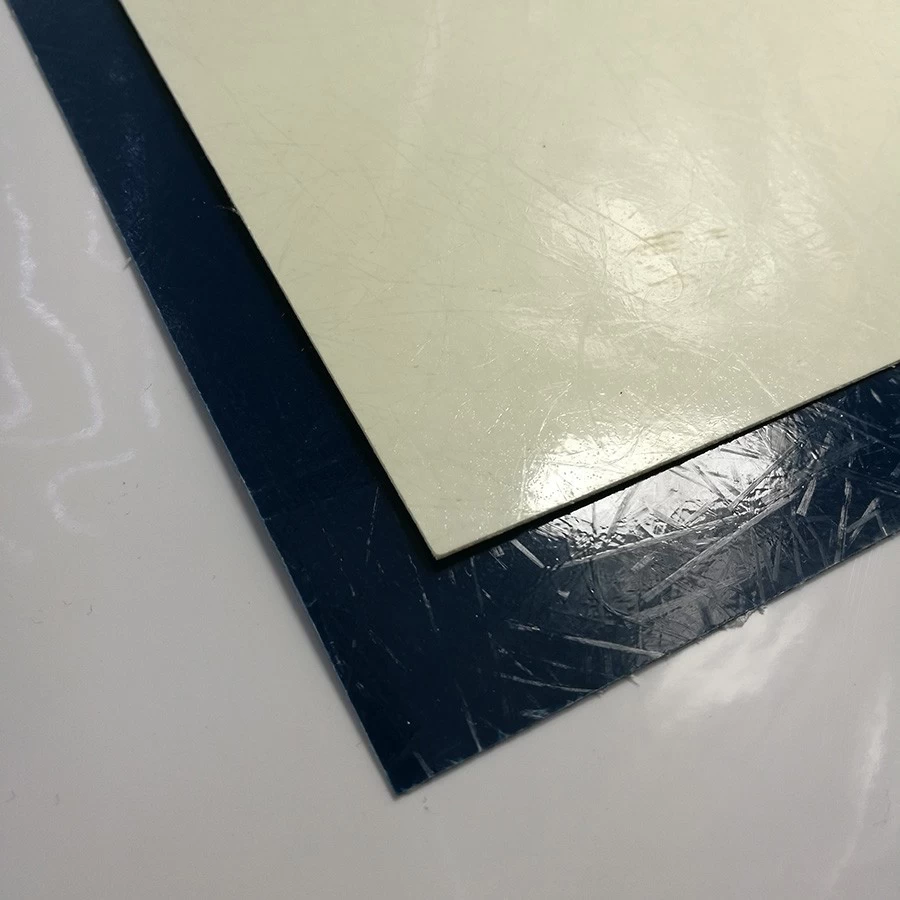

- Thickness:1.0-5.0mm

- Width:<2500mm

- Length:100 meters per roll or Customized

- Density:1.45g/cm3

- Tensile strength:124MPa

- Bending strength:195.8MPa

- Service:Cutting and Free sample

- Main market:North America, Europe, southeast Asia, Brazil, the Middle East

- Product name;Fiberglass Reinforced Plastic FRP Sheet

Introduction

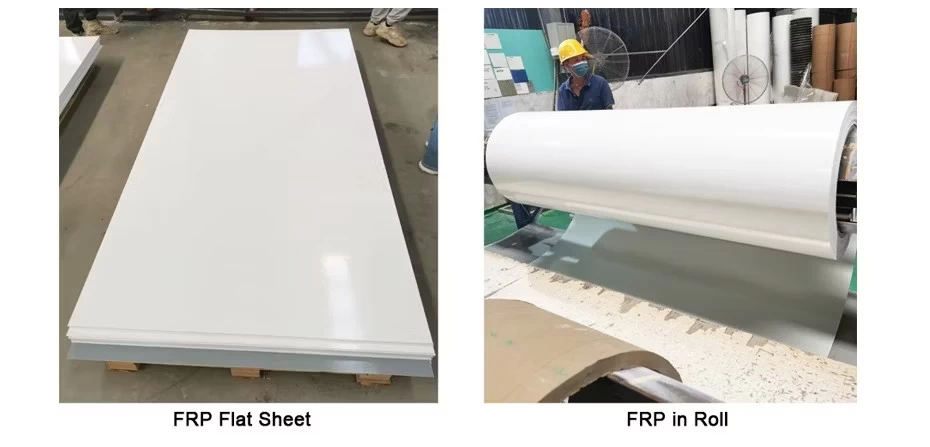

In the world of construction and manufacturing, choosing the right materials can significantly impact the outcome of a project. When it comes to fiberglass, it offers a wide range of applications due to its exceptional strength, durability, and versatility. Two common forms of fiberglass materials used in various industries are fiberglass flat sheets and fiberglass flat sheets in rolls. In this article, we'll explore the characteristics, advantages, and ideal uses of these two fiberglass forms to help you make an informed decision for your specific project.

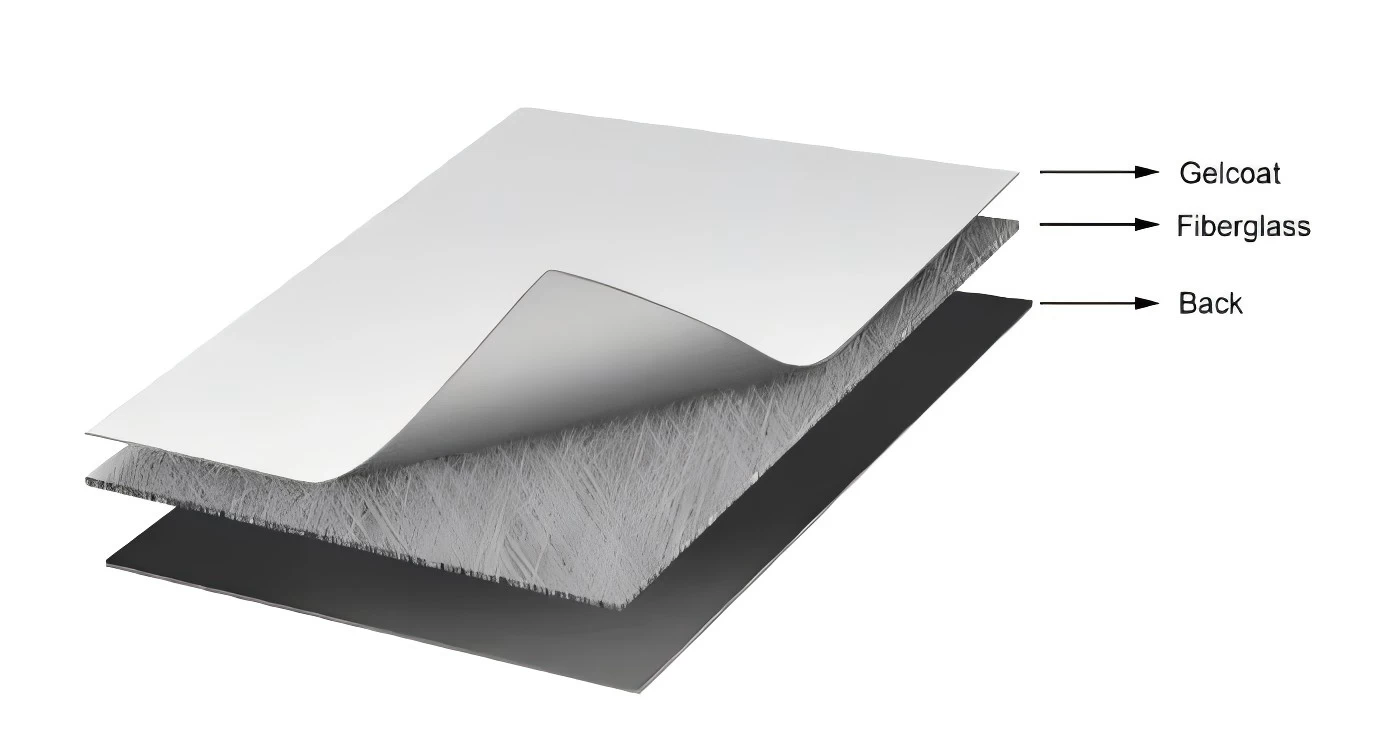

Fiberglass Flat Sheets

Fiberglass flat sheets are solid panels made from layers of fiberglass fabric saturated with a thermosetting resin, typically polyester or epoxy. These sheets are manufactured in various sizes and thicknesses, allowing for flexibility in choosing the right dimensions for a particular application.

Advantages of Fiberglass Flat Sheets:

-

Strength and Durability: Fiberglass flat sheets are known for their impressive strength-to-weight ratio, making them exceptionally strong and durable. They can withstand a wide range of environmental factors, including moisture, UV radiation, and temperature fluctuations, without compromising their structural integrity.

-

Chemical Resistance: Fiberglass flat sheets are highly resistant to chemicals and corrosion, making them suitable for use in harsh industrial environments where exposure to corrosive substances is a concern.

-

Fire Resistance: Many fiberglass flat sheets are designed to be fire-resistant, adding an extra layer of safety in buildings and applications where fire hazards are a concern.

-

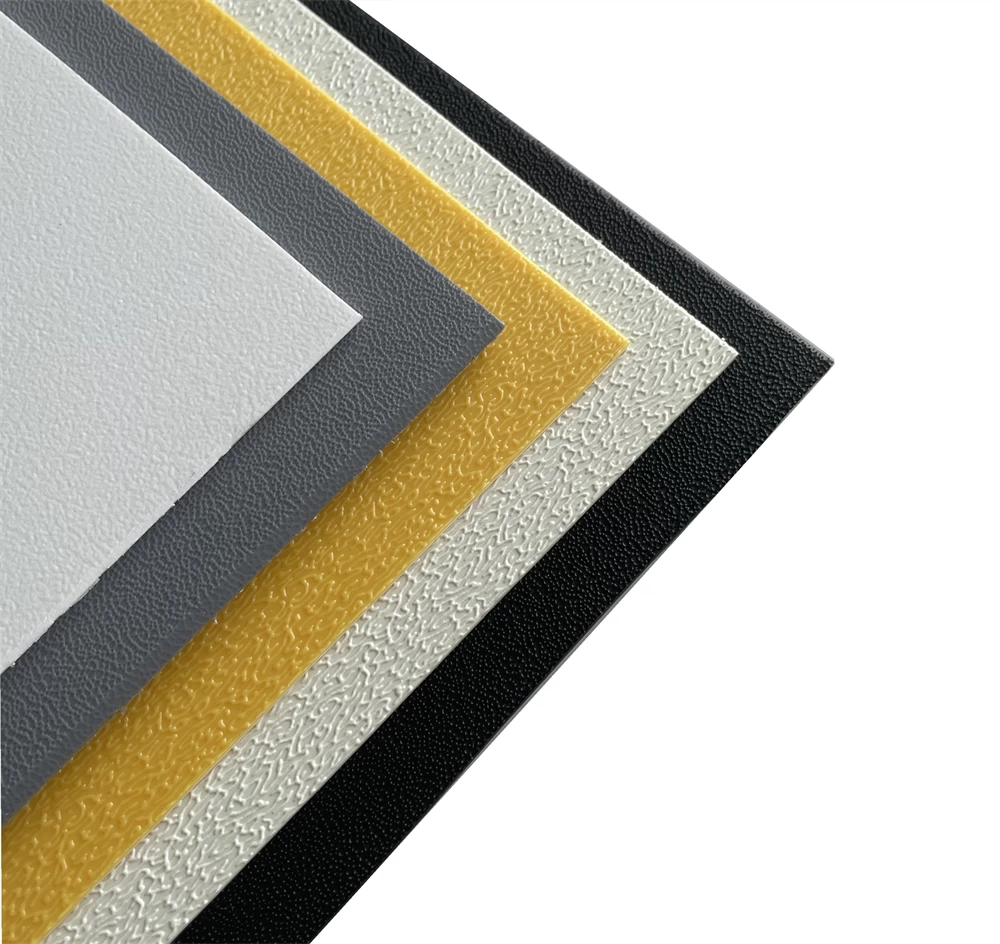

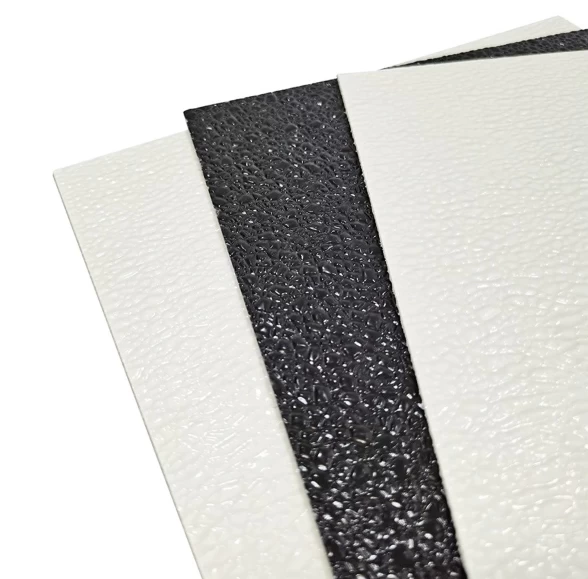

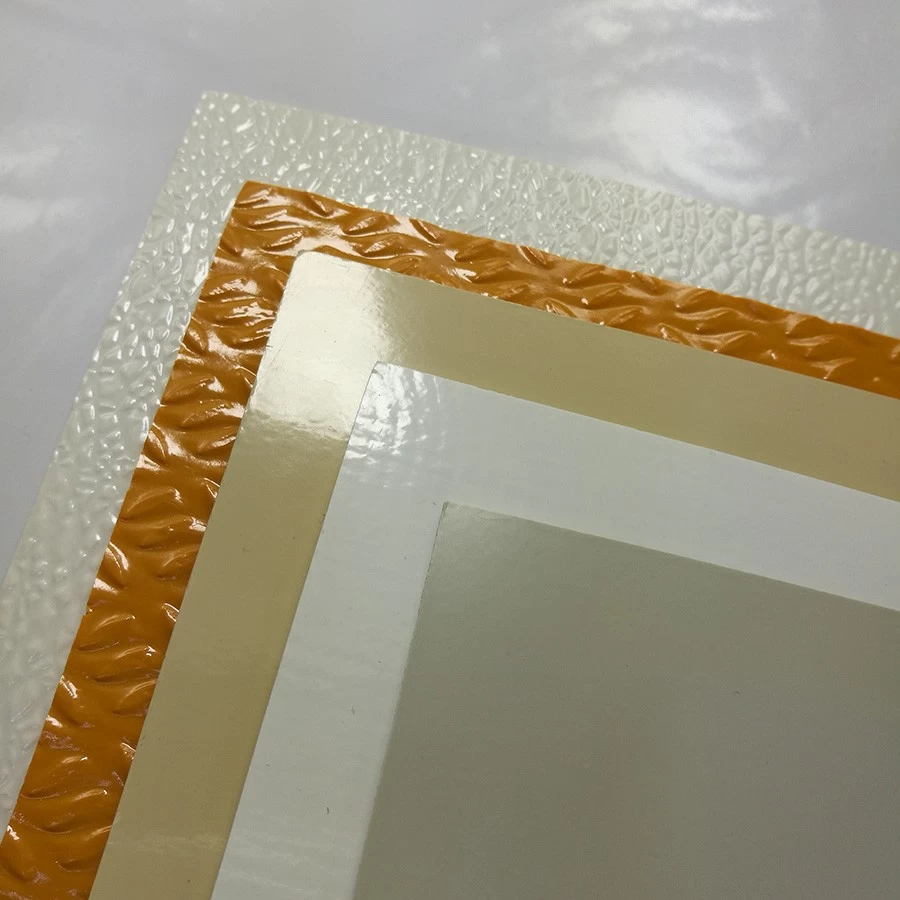

Customizability: These sheets can be easily cut, drilled, and shaped to fit specific project requirements. They also come in various colors and finishes, making them suitable for both functional and aesthetic applications.

Common Uses for Fiberglass Flat Sheets:

- Wall panels in cleanrooms and laboratories

- Boat hulls and marine applications

- Structural components in buildings

- Automotive parts

- Aerospace components

- Electrical insulation

Fiberglass Flat Sheets in Rolls

Fiberglass flat sheets in rolls are essentially continuous sheets of fiberglass material wound into a roll, similar to a carpet roll. This form offers several advantages over individual flat sheets.

Advantages of Fiberglass Flat Sheets in Rolls:

-

Versatility: The roll format allows for easy transportation and storage, making it a practical choice for large-scale projects. The continuous nature of the material also eliminates the need for seams, reducing the risk of leakage or weak points in applications such as roofing.

-

Efficiency: Installation of fiberglass flat sheets in rolls is often faster and more efficient compared to cutting and fitting individual sheets. This can lead to cost savings on labor and installation time.

-

Reduced Waste: Rolls can be cut to the desired length, minimizing material waste compared to pre-cut flat sheets, which may result in unused scraps.

Common Uses for Fiberglass Flat Sheets in Rolls:

- Roofing membranes

- Liners for tanks and pipes

- Insulation material

- Flooring and decking

- Wall coverings

- Reinforcement for composite materials

|

Textured With high impact resistance, ensuring they withstand collisions, abrasions, and rough handling, preserving the appearance and functionality |

|

Smooth

easy to clean and maintain

offering a smooth finish that resists dirt, grime, and stains for hassle-free upkeep.

|

|

>>FRP Sheet date

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

||

>>Company Profile

Welcome to Shenzhen Hongfu Tongxin Technology Co., Ltd! Shenzhen Hongfu Tongxin Technology Co., Ltd is a professional manufacturer of glass fiber products and plastic products. Our group had two factories, one is FRP production in Dongguan, the other is plastic sheet extrusion and vacuum forming in Foshan. We have been in fiberglass products and plastic products processing and customized design industry for 16 years, and have rich experience in providing project solution with excellent service. We are not only material suppliers, but also the provider of project solutions. We appreciate your visit on our site, welcome to contact us!

FAQ

1. Can I order panels to my exact dimensions ?

Yes,so panels are ready to be mounted to the exact dimensions required.color and profiles can be customized according to your request.

Q2: What´s the MOQ?

A: 500 meters

3. How are your panels packed ?

There's protective film on both sides of each panel.

Panels then into pallet.

These packs are covered with polythene to protect the panels during transport.

Each pack is placed on wooden supports to facilitate unloading either using straps or with a fork-lift.