What precautions should be taken when using tidal irrigation mobile seedbeds in greenhouses?

What precautions should be taken when using a hand-cranked mobile seedbed in a greenhouse: 1. Hardened greenhouse ground. When installing a mobile seedbed in a greenhouse, the ground is typically partitioned and hardened, leaving a 0.8-meter-wide gravel path beneath the seedbed for water seepage. The gravel path is flanked by a 0.8-meter-wide hardened pavement. The seedbed legs are 1.08 meters wide and positioned directly above the gravel path, leaving 0.3 meters on each side of the hardened pavement, ensuring a normal working space.

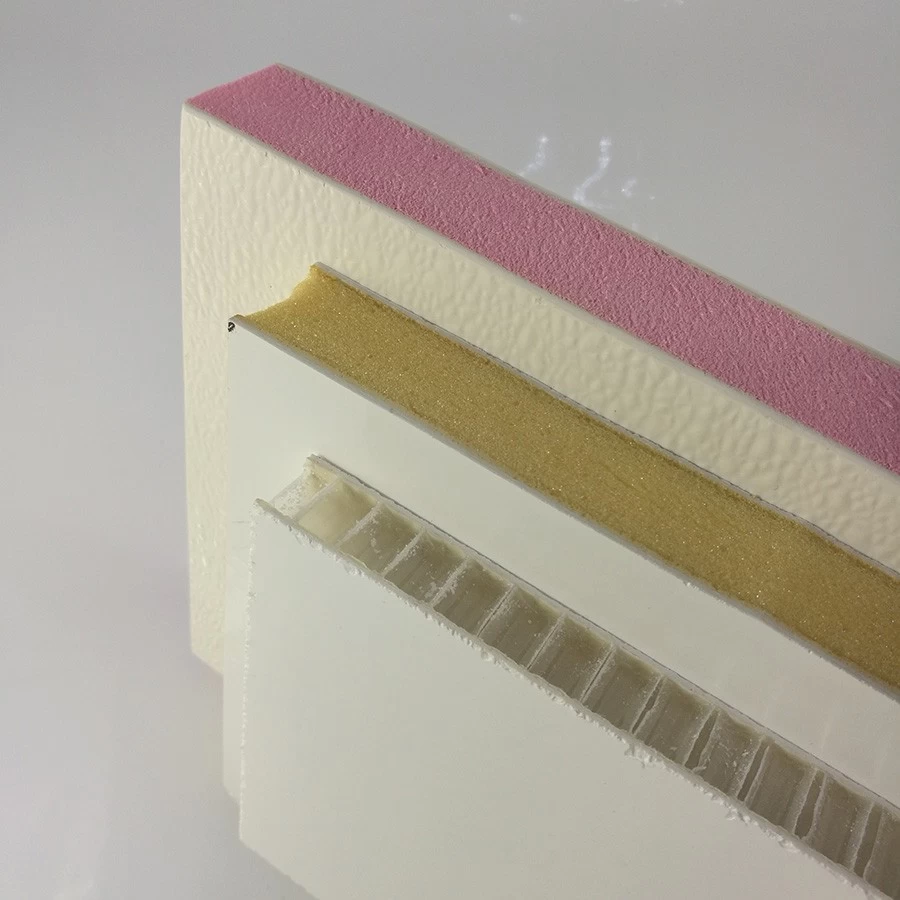

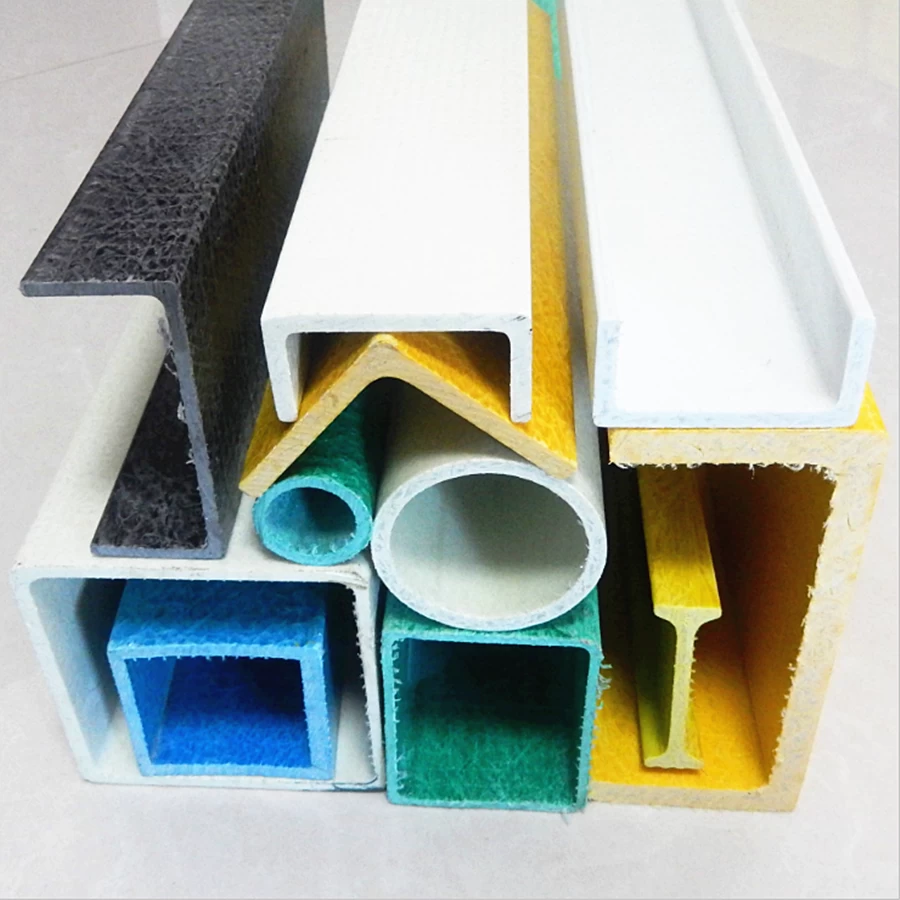

Installation and Commissioning of the Mobile Seedbed Structure: From bottom to top, the seedbed structure consists of: a seedbed base (with height adjustment), seedbed legs (typically 20*40*2.0mm hot-dip galvanized pipes), roller pipes, seedbed cross pipes, seedbed string pipes, seedbed mesh, seedbed frame, handwheel, seedbed frame corners, seedbed leg plugs, and anti-tip latches. First, secure the seedbed base to the hardened pavement with expansion bolts. Then, secure the seedbed legs and base with hot-dip galvanized bolts. Once everything is secure, perform a uniform leveling and fine-tuning.

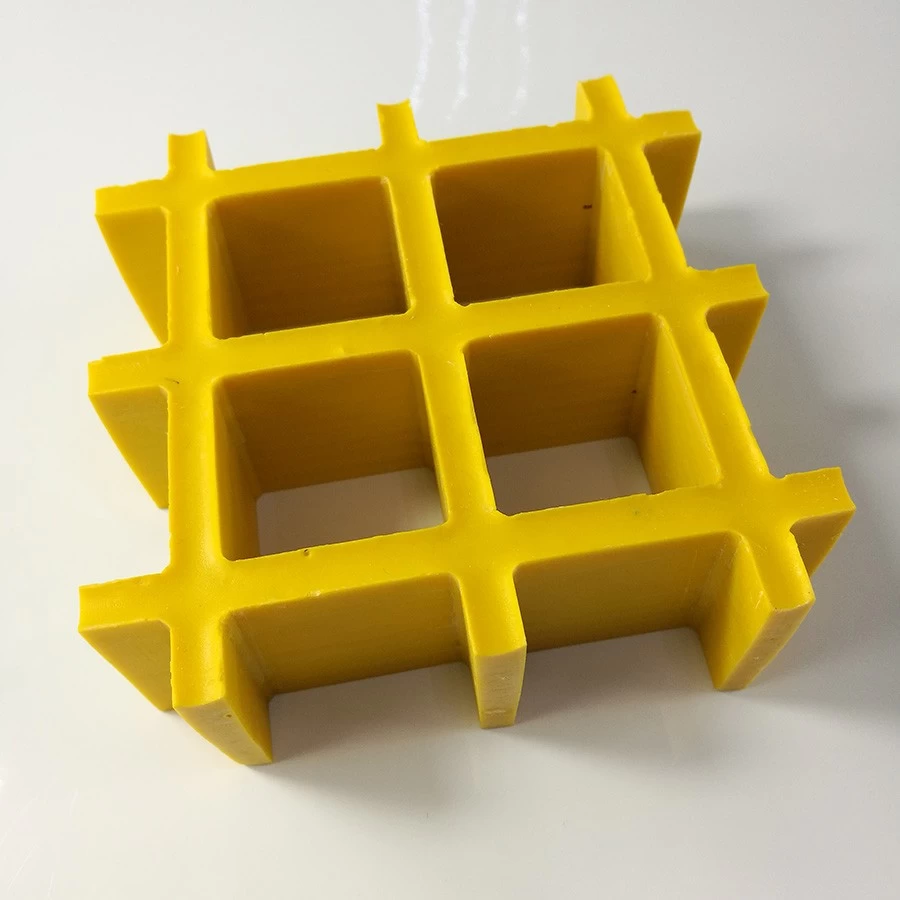

After the greenhouse seedbed legs are leveled, install the seedbed roller tubes, cross tubes, and diagonal braces in sequence. Note that there should be four diagonal braces; fewer will result in poor support. The distance between seedbed legs is generally two meters, and the distance between cross tubes is normally 0.65 meters. When securing the seedbed mesh and frame, pay attention to the location of the anti-rollover clips underneath. These clips prevent the seedbed from rolling further after it has rolled 30 centimeters.