- 1.Are you a factory or trading company?

- 2.How to send inquiry?

- 3.Do you accept customized products?

- 4.How to get sample?

- 5.Why choose us

- 6.Will you keep my information safe?

- 7.What kind of shipping method?

- 8.Lead time?

- 9.Is customized package available?

- 10.Polypropylene (PP) Sheet: A versatile sheet for diverse applications!

- 11.What is HDPE Sheet?

- 12.How does aluminum honeycomb perform?

- 13.What crops are suitable for tidal bed irrigation systems?

- 14.Can't be ignored! 5 common problems and solutions of FRP skylights in use

- 15.How to make payment?

- 1.Are you a factory or trading company?

-

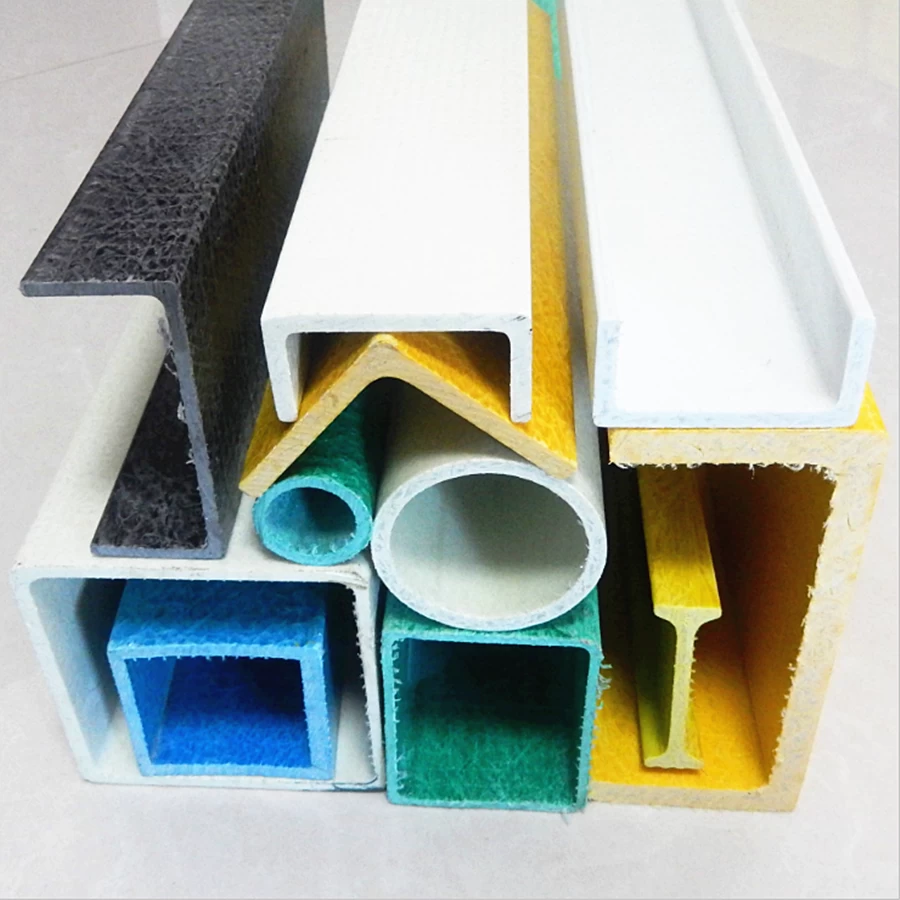

We are a factory has more than 16 years experiences in fiberglass reinforced industry and plastic sheet extrusion industry

- 2.How to send inquiry?

-

1) Send inquiry directly to our sales email.

2) Add other contact ways such as skype, wechat, whatsapp etc.

3) Or leave the message on the product information below.We will get back to you within 24 hours. - 3.Do you accept customized products?

-

Yes, ODM or OEM both OK.

You could tell us you requirements, we can discuss designs together,

Or send us 3D drawings, we will produce according to your drwaings - 4.How to get sample?

-

Just email us or contact via other contact ways, and tell us details of which series products & which product samples you need.

- 5.Why choose us

-

1.High quality product to suit your needs

2.Reliable customer service in 24 hours.

3.Fluent English communication for you todiscuss easily.

4.Fast delivery, usually can ship out 3days after get your deposit

5.Customized or OEM design is acceptable. - 6.Will you keep my information safe?

-

We will take seriously ofcustomers’ contact conformation and keep it confidential

Never ever share your informationto third party or other customer without your approval. - 7.What kind of shipping method?

-

Express: DHL,UPS.Fedex, TNT.EMS, etc.

Shipping by sea: from Shenzhen Port.

Air shipping: Shenzhen airport. - 8.Lead time?

-

If there is inventory, can be shipped out within 7 days.

If no stock, please contact us for detailed - 9.Is customized package available?

-

Yes, customized package is acceptable, just tell us your requirements, we will help you check.

- 10.Polypropylene (PP) Sheet: A versatile sheet for diverse applications!

-

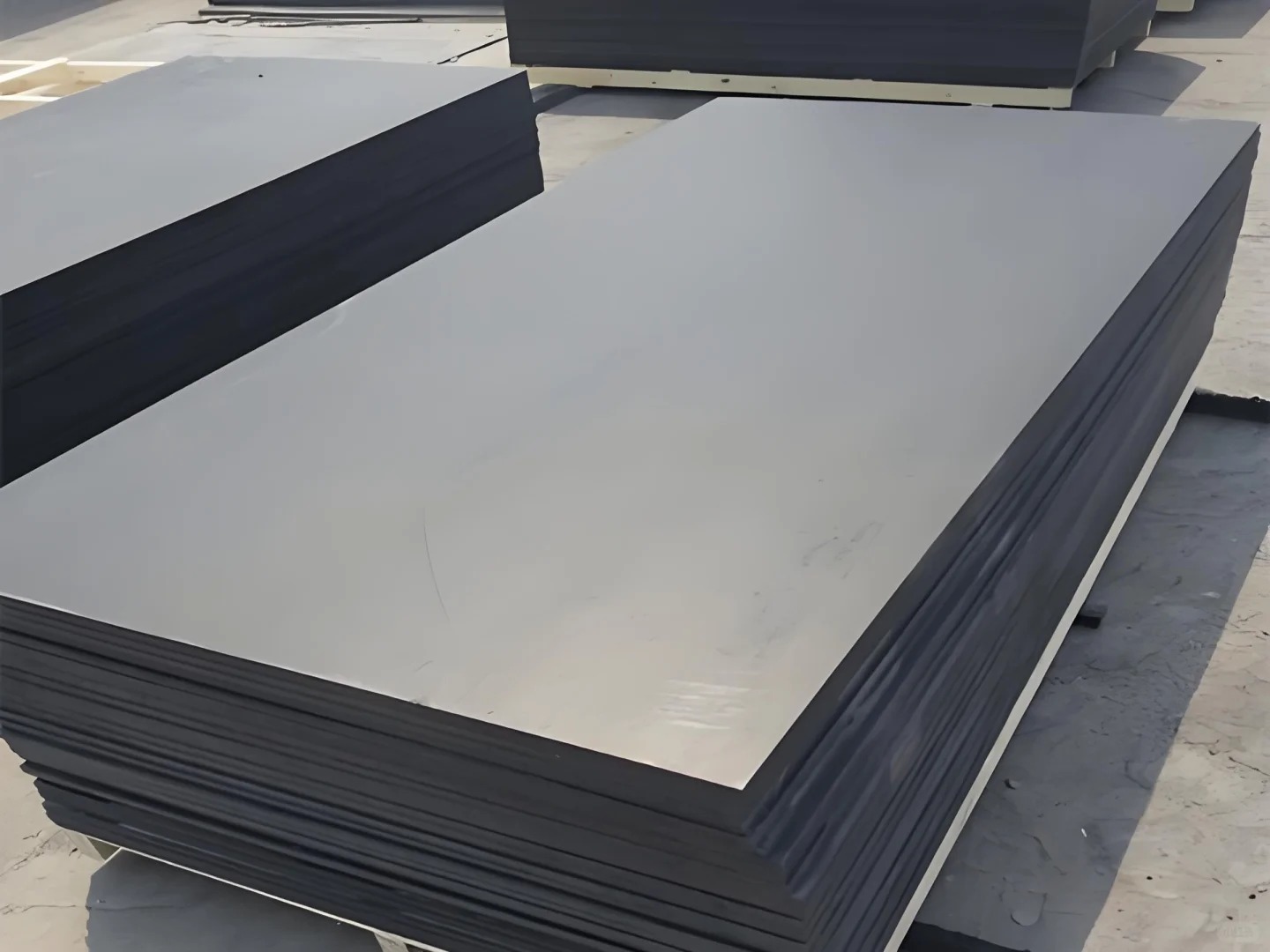

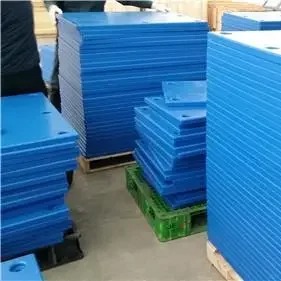

- 11.What is HDPE Sheet?

-

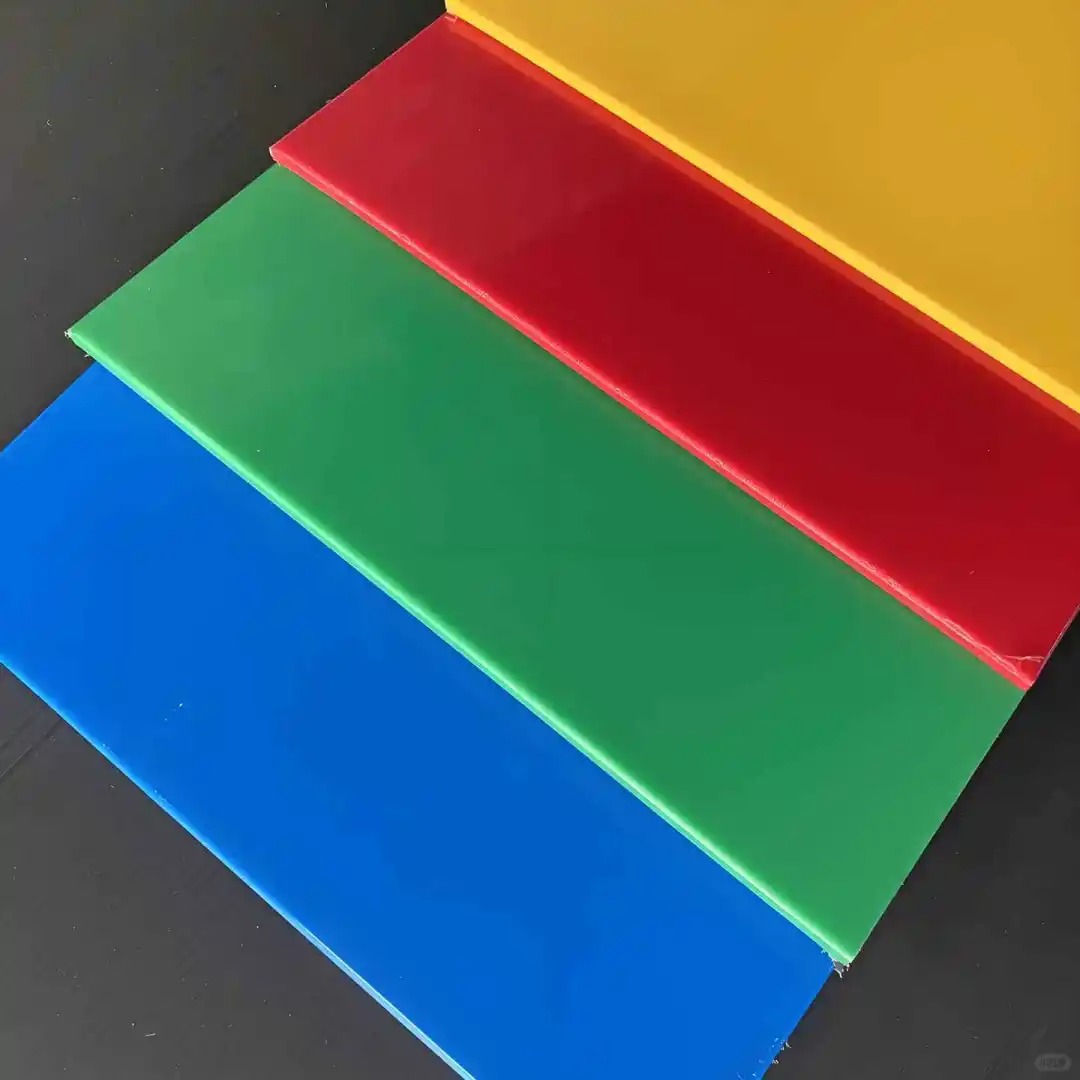

HDPE sheet, or high-density polyethylene sheet, is a plastic sheet made from high-density polyethylene (HDPE) resin through extrusion and pressing processes. Its excellent overall performance makes it widely used in a variety of fields. The following is a detailed introduction to HDPE sheet:

I. Performance Characteristics

Physical Properties:

Its low density (0.941-0.965 g/cm³) makes it lightweight and easy to transport and install.

Its smooth surface, low coefficient of friction, and excellent self-lubricating properties reduce wear when objects come into contact.

Its extremely low water absorption (typically less than 0.01%) and excellent water resistance make it suitable for use in humid or underwater environments.

Mechanical Properties:

It has high impact strength and maintains good toughness even at low temperatures (e.g., -40°C), making it resistant to brittle cracking.

It has moderate tensile strength and rigidity, allowing it to withstand certain loads. However, its low elastic modulus makes it susceptible to creep (slow deformation) under long-term stress.

It has excellent fatigue resistance and can withstand repeated bending or impact without damage.

Chemical Properties:

It is chemically stable and resistant to most acids, alkalis, salts, and organic solvents (such as alcohol and gasoline). However, it has poor resistance to strong oxidizing acids (such as concentrated nitric acid and sulfuric acid) and certain halogenated hydrocarbons (such as carbon tetrachloride).

It is odorless and non-toxic, meeting food hygiene standards and suitable for food contact applications.

Heat and Weather Resistance:

It has a wide operating temperature range, generally operating stably between -40°C and 60°C, and can withstand temperatures around 80°C for short-term use.

It has good weather resistance and some resistance to UV rays, but long-term exposure to outdoor sunlight may cause gradual degradation. This can be improved by adding antioxidants and UV absorbers.

Processability:

It is easy to process and can be processed through cutting, welding, drilling, bending, and other secondary processes. Welding can form a well-sealed integral structure.

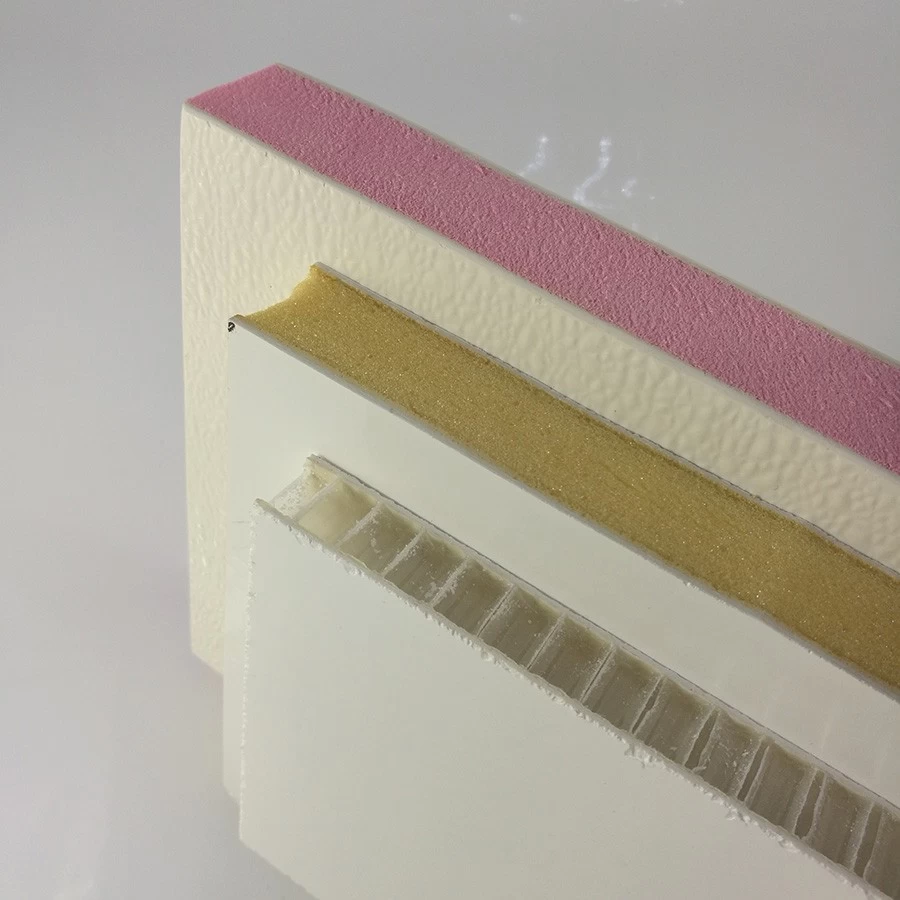

- 12.How does aluminum honeycomb perform?

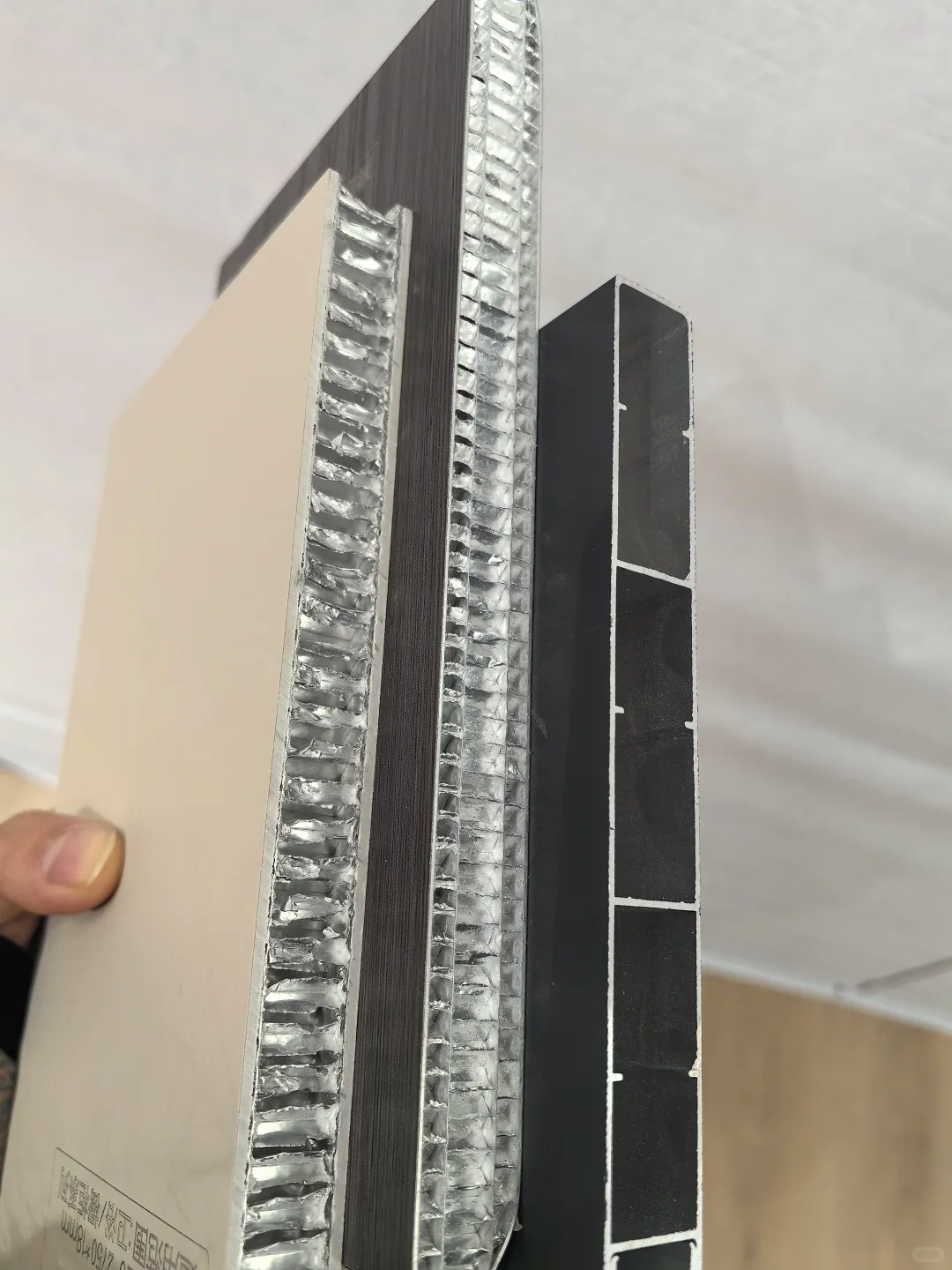

-

- Lightweight and High-Strength: The unique honeycomb structure of honeycomb aluminum makes it lightweight and easy to transport and install. It can also withstand significant pressure and resist deformation, ensuring the cabinet's durability.

- Sound and Heat Insulation: The honeycomb-shaped air cavities effectively block the transmission of sound and heat, providing excellent sound and heat insulation, making the cabinet suitable for spaces requiring sound and heat insulation.

- Moisture and Fireproof: Aluminum itself is moisture-resistant and unaffected by moisture. Furthermore, honeycomb aluminum is an inorganic material, non-combustible, and has a high fire rating, enhancing home safety.

- Corrosion Resistance: Aluminum easily forms an oxide film on its surface, providing strong corrosion resistance. Honeycomb aluminum cabinets are resistant to rust and corrosion in all environments, ensuring a long service life. - 13.What crops are suitable for tidal bed irrigation systems?

-

1. Vegetable crops such as tomatoes, cucumbers, eggplants, lettuce, and spinach grow quickly and maintain high quality in tidal beds.

2. Flower crops such as roses, African violets, and carnations. Tidal beds provide stable water and nutrients for flowers, helping to improve their quality and yield.

3. Herbal crops: Some herbs that require meticulous care, such as mint and rosemary, are also suitable for growing in tidal beds.

4. Seedling crops: Tidal beds are particularly suitable for raising seedlings. Whether it's vegetables, flowers, or other cash crops, seedlings can grow well in this system. - 14.Can't be ignored! 5 common problems and solutions of FRP skylights in use

-

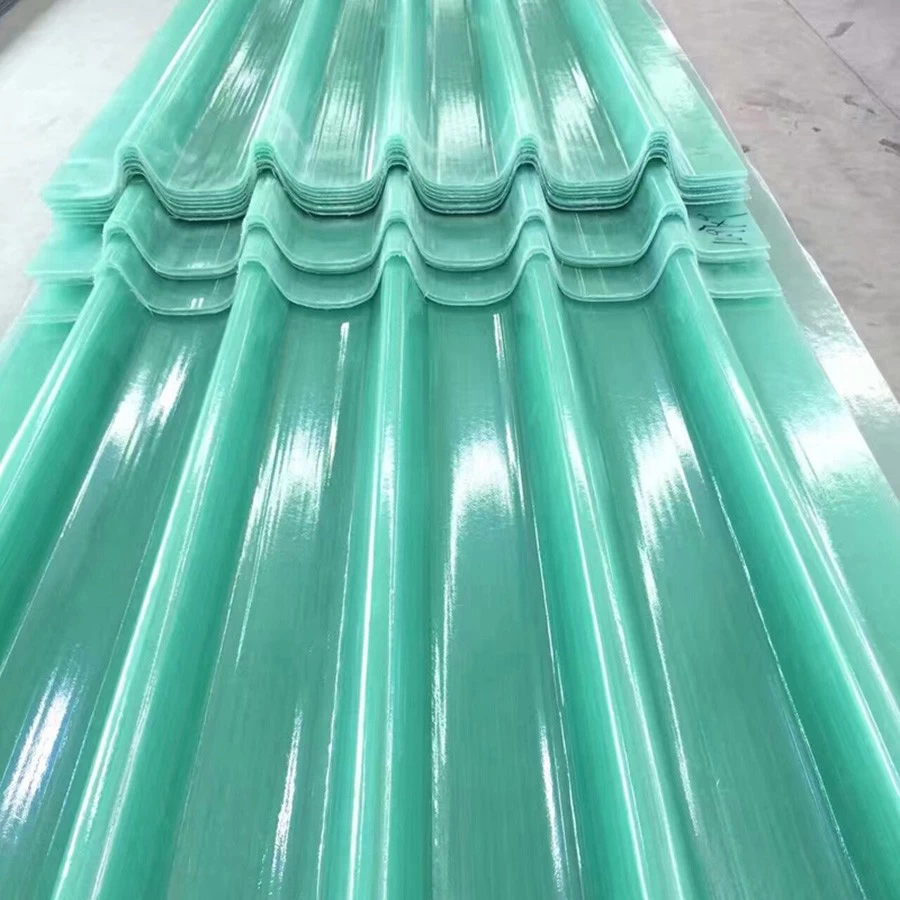

In today's building materials market, FRP (glass reinforced plastic) skylights have become an indispensable material with its excellent performance and economic benefits. However, even such high-quality materials will inevitably have some common problems during use.

Problem 1: Color fading

FRP skylights are exposed to sunlight for a long time, and ultraviolet rays may cause the color to gradually lose its original brightness.In order to solve this problem, you can choose products with anti-UV layers or UV stabilizers added to the materials when purchasing, which can effectively extend the color life of the skylights.

Problem 2: Strength reduction

Over time, FRP skylights may experience a decrease in strength, which is mainly due to erosion from the external environment.In response to this problem, regular surface cleaning and maintenance are necessary. In addition, choosing high-quality FRP materials, their better weather resistance can also slow down the decrease in strength.

Problem 3: Leakage

Leakage is one of the common problems in the application of FRP skylights. Once leakage occurs, it not only affects the lighting effect, but may also cause damage to the interior of the building.Ensuring proper sealing during installation is the key to preventing leakage. If leakage has occurred, check the sealing strips at the joints as soon as possible and replace them if necessary.

Question 4: Contamination and Cleaning

Contaminants such as dust and other residues will adhere to the surface of the FRP skylight, affecting its light transmittance. Therefore, it is particularly important to clean the skylight regularly.Manual cleaning with a mild detergent and a soft cloth is the simplest and most effective method, while avoiding the use of highly corrosive detergents to avoid damaging the panels.

Question 5: Thermal Expansion and Contraction

FRP skylights will expand and contract due to temperature. If this is not taken into account during installation, it may cause the panels to crack or deform.Therefore, appropriate expansion gaps should be reserved during installation to accommodate temperature changes. At the same time, choosing FRP skylights with good thermal stability can also reduce the occurrence of this problem.

- 15.How to make payment?

-

We accept Paypal, Credit card, TT transfer, Alibaba, Western Union etc.