- Browse Categories

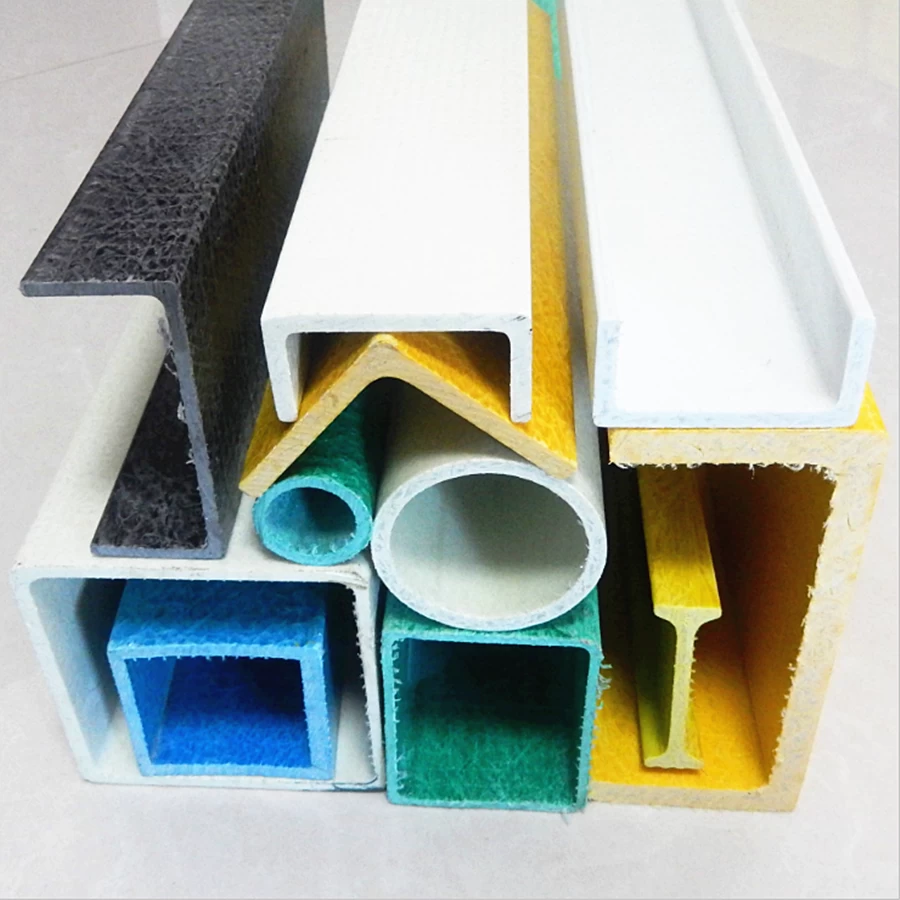

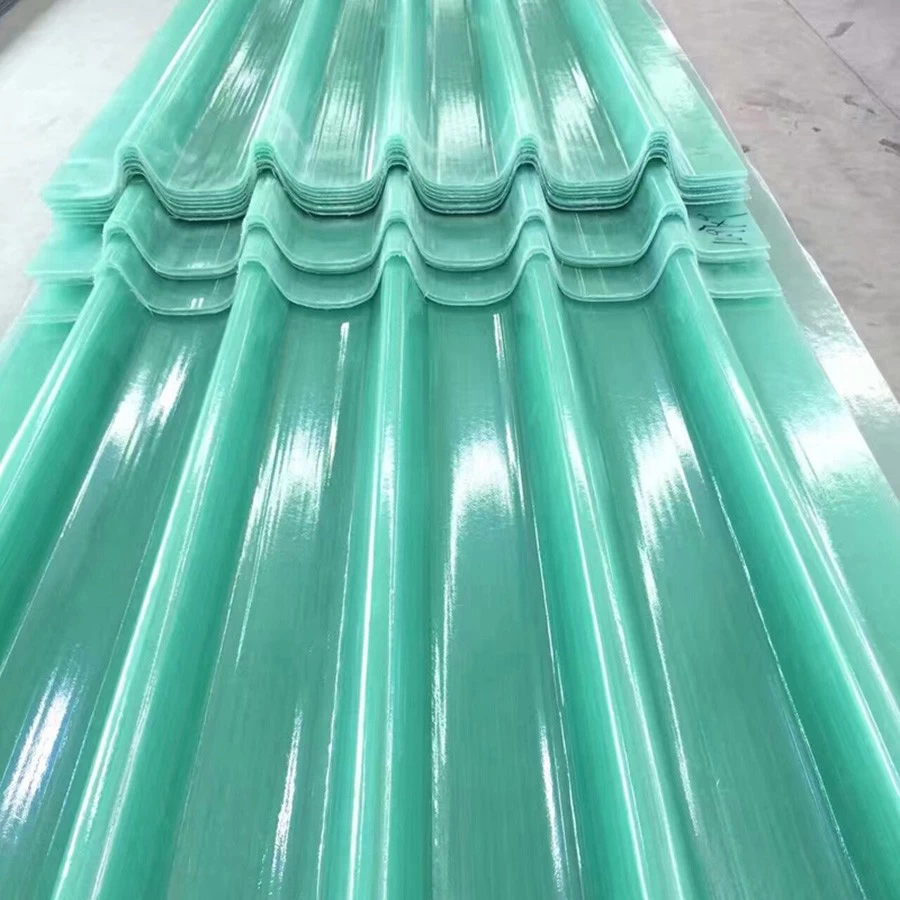

- FRP Product

- Plastic Product

- ABS Sheet

- HIPS Sheet

- PP Sheet

- HDPE Sheet

- Hydroponic Tray

- Vacuum Forming Processing

- Subscribe

-

Get email updates on new products

- Contact Us

-

Telephone: +86-0755-28329102

Mobile Phone: +86-15814411453

Fax: +86-755-28998345

Address:Room 02, 32 Floor, 6 block, Phase 3, Xieli Garden, Longcheng Street, Longgang District, Shenzhen

Zip:518172

Country/Region:China (Mainland)

Province/State:Guangdong

City:Shenzhen Contact Now

- FRP Product

- News

-

How to Choose Refrigerated Truck Body Panels

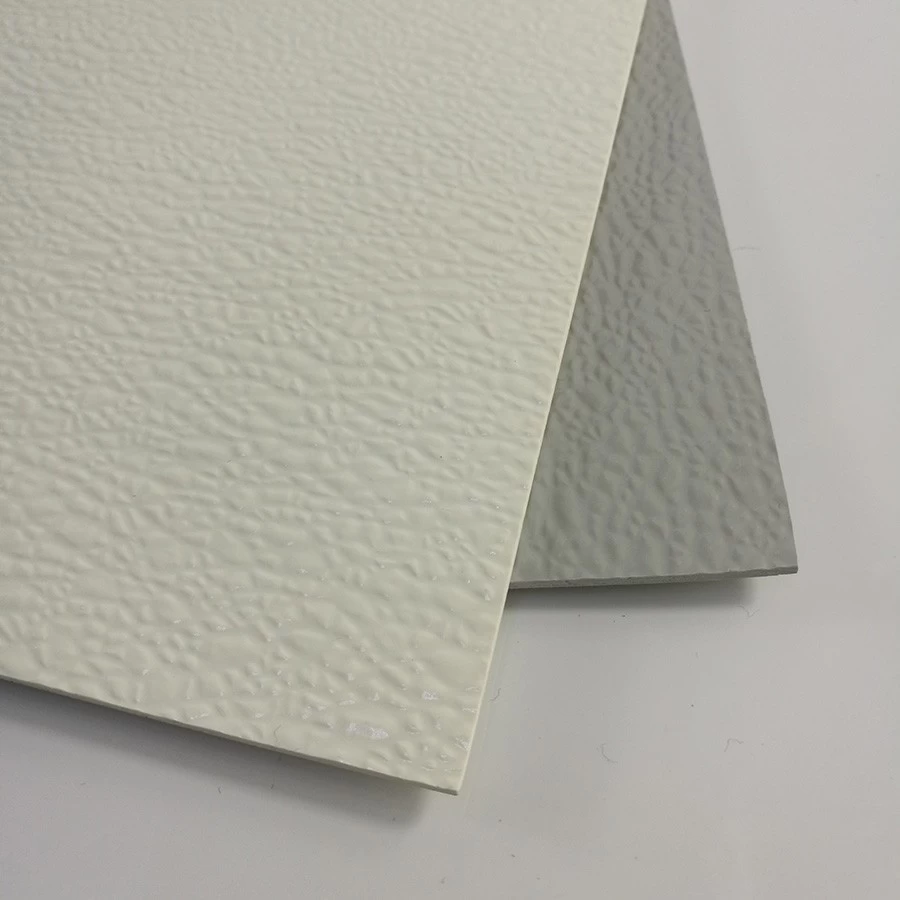

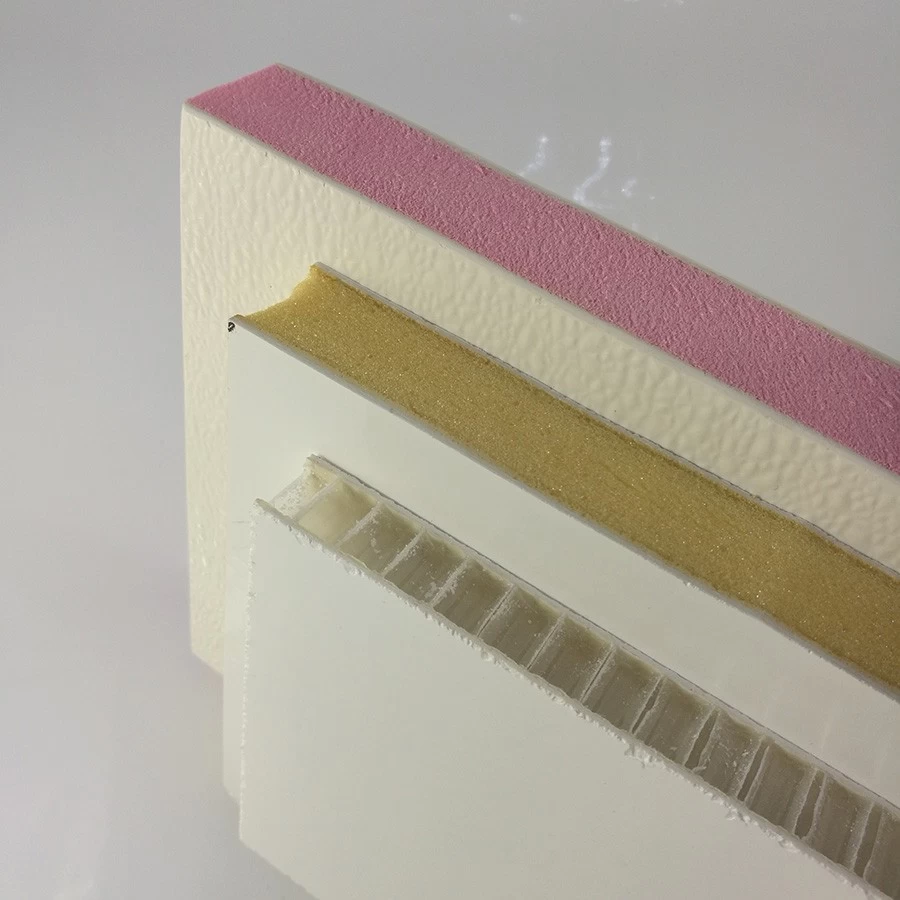

Due to cost, installation and construction, the refrigerated truck van panels were gradually made of FRP composite panels. FRP composite panels are made of FRP flats and used as two layers of the bottom and the top, in addition to the role of controlling the weight, and also have good impact resistance. The middle layer uses different kinds of core materials, such as PP honeycomb core material, XPS core material, PU core material, etc.,The differences between FRP mechanism sheet and Hand Lay-up sheets

At the beginning of the industry, manpower was usually used to make FRP, but most manufacturers use production line to produce FRP sheet now. FRP mechanism sheet gradually replaced hand lay-up sheet. The FRP mechanism sheet has many advantages over the hand lay-up. The FRP mechanism plate has stable quality and uniform thickness. Cost-effective, neat and shiny surface.Hydroponics Overview Technique and Advantages

1) Hydroponic OverviewHydroponics is a new type of plant soilless culture method, also known as nutrient solution culture. Its core is to directly inf...Can Flame-retardant Fiberglass Lighting Roofing Panels Be Still Used After Yellowing?

A, Fire-retardant FRP lighting roofing panels are mainly used in steel mills and blast furnaces with high temperatures, fire point splashes or some sp...ABS Sheet Performance and Applications

ABS sheet is an emerging material in the plastic sheet industry. The full name is Acrylonitrile butdiene styrene. It is a polymer with a relatively la...RV Traveling Are Getting More and More Popular

Do you know what a RV is? The concept of the beginning of RV is “movable house”. The RV has all the necessary items for life, including bedr...FRP Gratings Applications

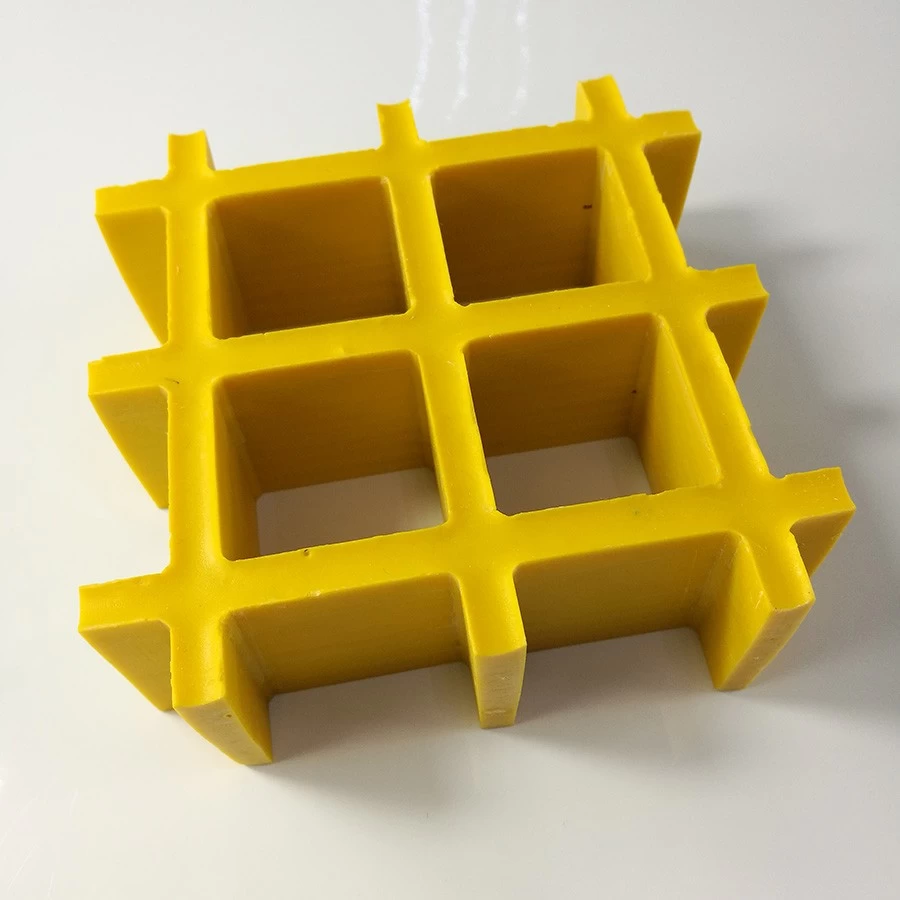

Thanks of the excellent properties of FRP gratings, they are replacing carbon steel, stainless steel, wood and non-ferrous metals. The fiberglass gra...FRP Sheet & Panel Project

Fibre Reinforced Plastic (FRP) Grating Description

The Fibre Reinforced Plastic (FRP) grating is a moulded, one-piece fibreglass reinforced plastic grating, available in standard panels or fabricated i...FORE PP Sheet for Tanks

FORE PP Sheet for Tanks Foreth PP Sheet has good acid and alkali resistance properties,excellent welding processability and non-toxic environmental ...

China OEM ABS HIPS HDPE Plastic Uptake Thermoforming Process Factory

- Material: ABS, PS, HDPE, PP, PMMA, PC, PMMA/ABS, PC/ABS etc.

- Max size: 2000x4000x800mm

- Thickness: 0.8mm - 12mm

- Color: White, Black, Red, Yellow or customized

- Logo: Sticker & Screen Print etc

- Surface: Matte, Glossy, Textured, Paiting, Chrome, Customized

- Service: OEM or ODM

- Process: Plastic Sheet extrusion, Vacuum forming and CNC processing

China OEM ABS HIPS HDPE Plastic Uptake Thermoforming Process Factory

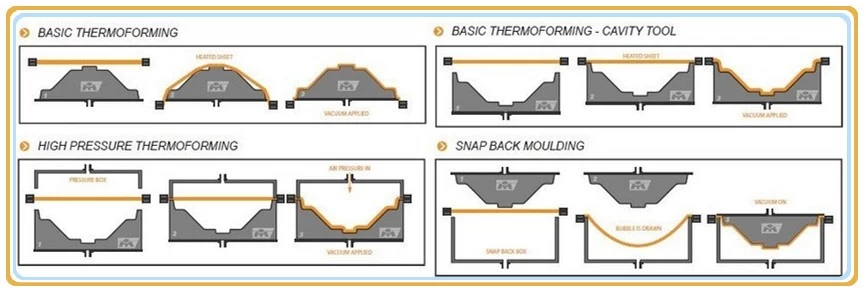

A. Thermoforming Process Description

Vacuum forming is a simplified version of thermoforming, whereby a sheet of plastic is heated to a forming temperature, stretched onto or into a single-surface mold, and held against the mold by applying a vacuum between the mold surface and the sheet. The vacuum forming process can be used to make most product packaging and speaker casings. It is also used to fabricate car dashboards. The first commercial manufacturer of vacuum-formed plastics was Robinson Industries of Coleman, Michigan.

B. Thermoforming Process schematic diagram:

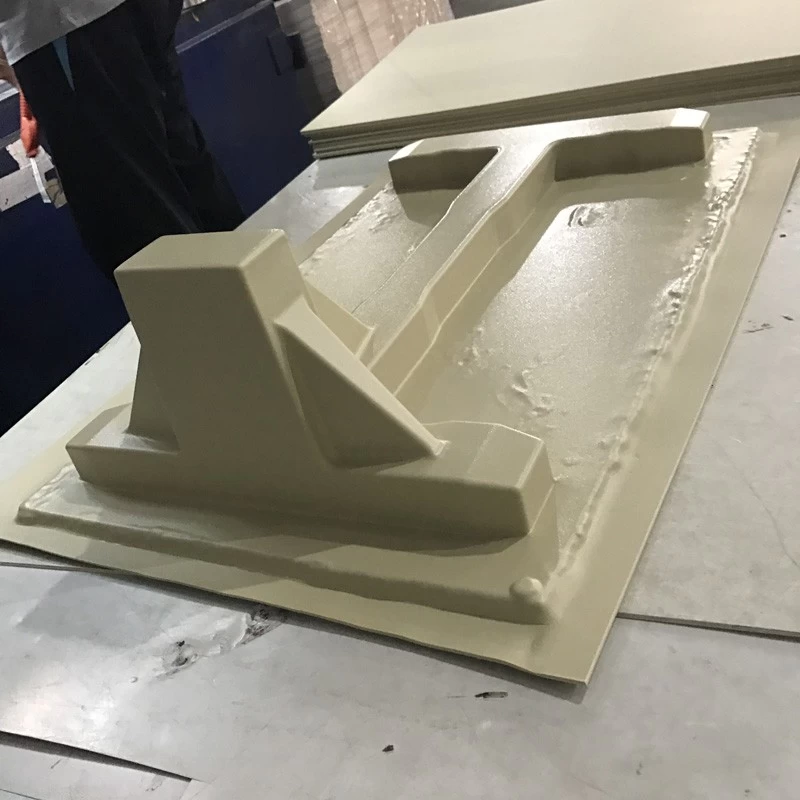

C. Thermoforming Process production steps

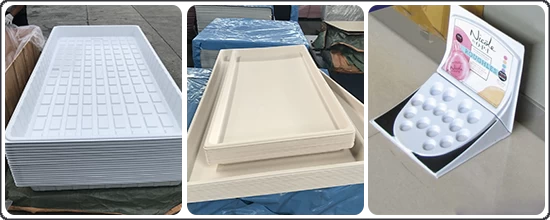

D. Thermoforming Process Products

| Main Category | Products | Images |

| Plastic Trays | Hydroponic Trays |  |

| Pet Trays | ||

| Makeup Trays | ||

| Plastic Auto Parts | Car Mats |  |

| Car Roof Box | ||

| Pickup Bed Liner | ||

| Plastic Cover & Shell | Antenna Radome |  |

| Surfboard Cover | ||

| Equipment Shell | ||

| Advertising & Display | Sign Board |  |

| Light Box | ||

| Display Stand | ||

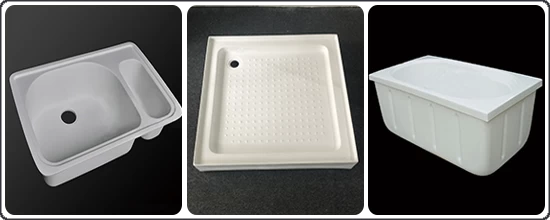

| Bathroom Products | Wash Basin |  |

| Shower Tray | ||

| Bathtub |

E. Package & Delivery

| Package | Delivery |

| 1.Packed on plywood pallet | 1. Samples: 2-3 dyas |

| 2.Packed in plywood case | 2. Mass production: 7-15 working days after receive payment |

| 3.Load in container directly | 3. Delivery terms: EXW, FOB. CIF, DDP all can be accepted |

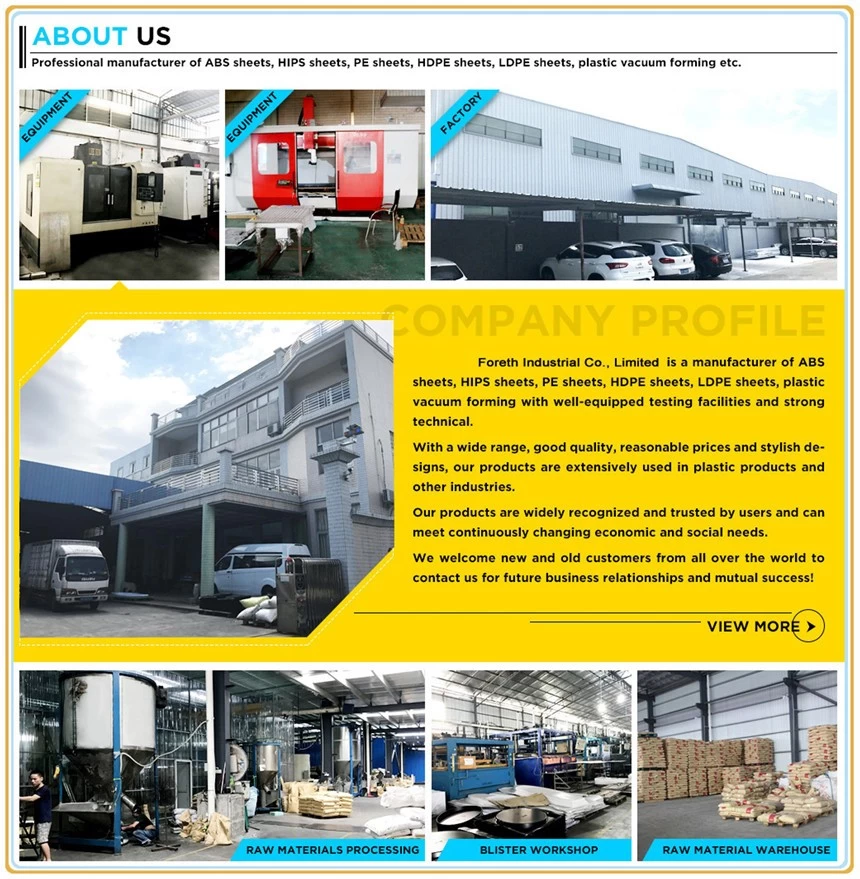

F. Factory Profiles

We are the largest-scaled and best-equipped manufacturer in the field of plastic sheet and thick guage vacuum forming in china. We also own a well-experienced team--more than 15 years experience--of desingers and technicians, which enable us to supply you the most ideal products.

We integrate product design, prototype, tooling , vacuum forming, CNC trimming,silk-screen printing, spray painting,packaging in one company. In addition, we own our skilled acrylic displays craftsmen.All these help us to provide you with one-stop service from your designs/samples and even ideas to final products.

1. Raw material inslude PMMA, ABS, PS, PP, APET, PVC, PET, PET-G, and HIPS.

2. Plastic sheets max width can be 2000mm.

3. The Max forming products size can be 4000*2000*800mm.

4. The material thickness can reach 12mm.

5. we are able to do silkscreen, spray painting and prototype etc.

6. Products are widely applied in toy, catering, auto, mechanism, household appliance, tourism, printing, medical equipment, architecture, touring, advertising, furniture etc.

7. Lower tooling costs.

8. Extremely adaptive to customer design needs

We integrate product design, prototype, tooling , vacuum forming, CNC trimming,silk-screen printing, spray painting,packaging in one company. In addition, we own our skilled acrylic displays craftsmen.All these help us to provide you with one-stop service from your designs/samples and even ideas to final products.

1. Raw material inslude PMMA, ABS, PS, PP, APET, PVC, PET, PET-G, and HIPS.

2. Plastic sheets max width can be 2000mm.

3. The Max forming products size can be 4000*2000*800mm.

4. The material thickness can reach 12mm.

5. we are able to do silkscreen, spray painting and prototype etc.

6. Products are widely applied in toy, catering, auto, mechanism, household appliance, tourism, printing, medical equipment, architecture, touring, advertising, furniture etc.

7. Lower tooling costs.

8. Extremely adaptive to customer design needs

China OEM ABS HIPS HDPE Plastic Uptake Thermoforming Process Factory